Investing in additive manufacturing

Manufacturing is arguable one of the most important industries in our world. Unfortunately, the weight of that characterization holds back development to an extent. Rather than risking capitol on a future technology many businesses instead focus on what works for as long as possible before adopting something new. This conservative bet is understandable when opportunity costs can go through the roof while installing a new technology or methodology. But for a, relatively, new and exciting technology like additive manufacturing (AM) this has some unwanted effects, namely investment. Without companies investing in the technology it does not improve, and without improvement fewer businesses look to deploy it in their everyday operations. This is where external investment makes a big difference in adopting a new technology like AM – through private organizations and government intervention.

The latter is being spearheaded in the United States through initiatives like the Additive Manufacturing Forward Program, which connects industry experts, academic researchers, and government investment to accelerate the technology. And there is lots of precedent in these types of collaborations between private industry and public investment – even CNC saw collaboration between the US Department of Defense and IBM – to build further innovation into technologies. But the problem is moving these advancements out of research and development, into commercializable products. Rather than validating a technique is possible, it needs to be made viable in a business setting.

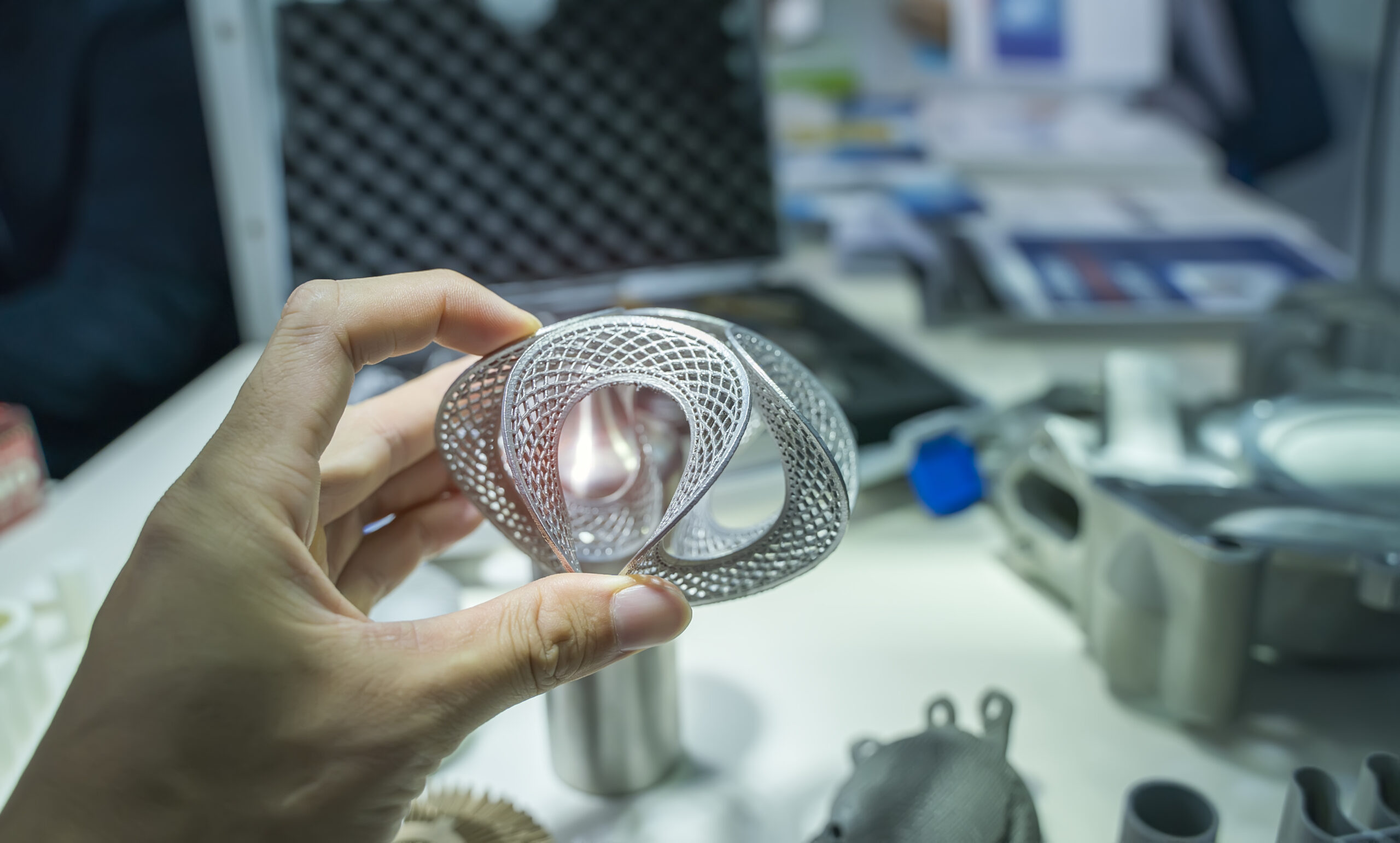

The AM problem is especially complicated and is why investment between government and private industry is so important. Public research provides the much needed data and innovations in the field, while private business adds the experience of how to deploy a technology profitably. But getting there requires bringing together a very diverse group to unravel AM to it’s fundamentals and rebuild it for the future – the technology relies on material science, software optimization, hardware innovations, process optimizations, and a variety of application industries. It is too much for any individual to be an expert on it all. Fortunately, the benefits of figuring out this problem are well worth the investment to many.

Whether the reasoning is geopolitical, environmental, or purely financial, many industries in the US are seeing a push for on-shoring and near-shoring – which mean bringing manufacturing closer to home. For decades, the manufacturing industry in the United States has waned and for a variety of reasons. But with that change a lot of the capability to manufacture things at home fell away – the experienced machinists retired or changed professions, the equipment was sold off or scrapped, and the business networks shifted to benefit globalized manufacturing. Additive manufacturing is seen as a way to bring manufacturing back home, partially because it can provide more value but also because the switch would already require a new set of skills, removing some of the advantage of incumbent factories. There may also be a negative consequence of not adopting AM for local manufacturing, global production is built for efficiency, not flexibility or resilience.

If you are in Chicago for IMTS 2022, you probably already know a lot about the investment being made. But if not there are a few other important ventures coming out of the private sector. EOS continues to reinvest in the technology with capital from AM Ventures, and they have been able to revolutionize the space with a variety of innovative applications. But a little closer to home, Siemens’ Next47 is funding startups around both hardware and software for additive manufacturing – one of the top examples being the investment in Markforged and their continuous-fiber reinforced printing process. But there is so much more, for information on the happenings at IMTS, check out AdditiveManufacturing’s coverage of the event. And be sure to check back here soon for a review of what you may have missed this year at IMTS 2022.

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram. Siemens Digital Industries Software – Where today meets tomorrow