Next generation MBSE solutions

The most important benefit of Model-Based Systems Engineering (MBSE) solutions versus traditional Systems Engineering tools is the use, and specifically reuse, of models throughout development. These models portray a variety of different variables in an interconnected system. For an automotive project that could be the interoperability between the vehicle’s input methods and the vehicle dynamics, this is essentially the different driving modes of a vehicle – winter, sport, gravel, etc. But one these models could enable an upfront balancing of project cost versus final product efficiency. Unfortunately, the growth of complexity in many multidisciplinary industries has far outpaced the modeling language which have underpinned many MBSE tools. The process is still very valuable, but the usability is far from idea to bring better products to market faster.

SysML v1 is not enough

The first version of System Modeling Language, or SysML v1, was originally developed for software applications. Over the years it has been expanded and augmented, partially through first party updates to the standard and partially through extensions created by software vendors and OEMs to make the language work with their MBSE processes. The small updates have not enough to expand the functionality of the standard however, the number of models that can be used simultaneously is very limited. A modern product can include engineering work from mechanical, electrical, electronic and software domains, often with multiple subsystems in each if not hundreds as would be found in a vehicle, aircraft or piece of industrial equipment. That can easily surpass the nine models that SysML v1 can accommodate natively, without even including the studies on risk, feasibility or cost breakdowns.

Some MBSE tool providers have extended the capabilities of SysML v1, though these are more often than not proprietary implementations and are not compliant with the standard. This means in the best case, any external suppliers or collaborators will need the exact same MBSE tool. But according to a 2019 report from CIMdata on MBSE data interoperability, sometimes files don’t function correctly when using the exact same MBSE tool. Customers working with complex designs are far more likely to have large and diverse supply chains, making interoperability paramount to a successful digital enterprise.

A new solution

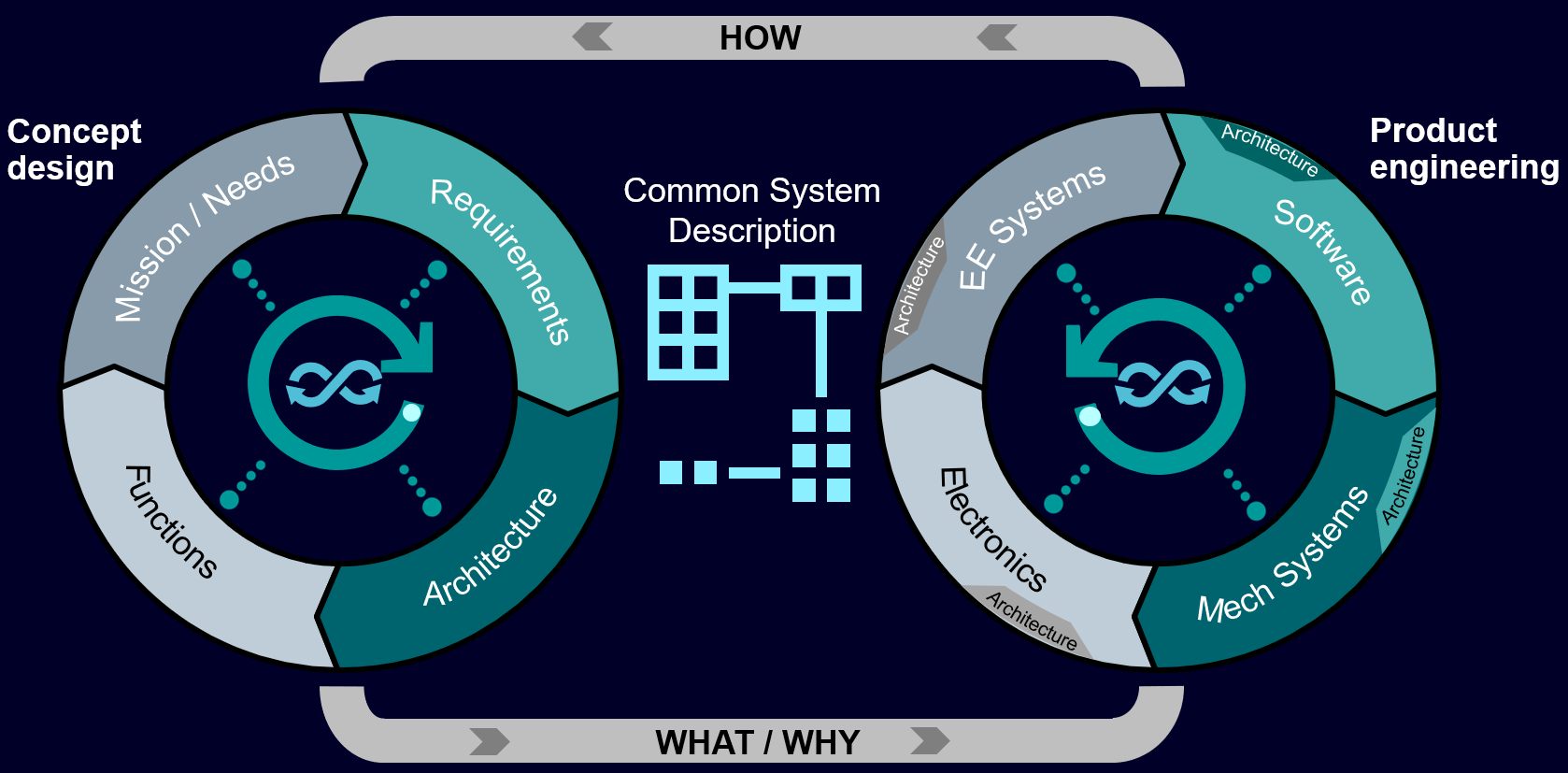

Compliance with a more robust standard is the key for a successful MBSE solution, which is why Siemens is commiitted to SysML v2, as stated in a co-authored piece by our heads of automotive and aerospace software groups – Nand Kochhar and Dale Tutt respectively. But what does that mean for the next generation MBSE solutions? Updating to SysML v2 will bring an increased number of usable system models, a greater selection of model types to create a wider product definition and break down the silos between engineering domains, all while retaining the connection to system requirements. This multi-domain architecture will drive downstream development throughout the enterprise, from in-house departments to suppliers across an ocean.

Standardizing the MBSE process is one of the most requested features by systems engineers in a recent SERC survey on the maturity of MBSE. Siemens Software understands this need, just like the need in CAD applications for a standardized viewing file format with JT. The updates to SysML will be an advancement similar to CAD’s progression from wireframes to photorealistic 3D models, but only with leadership and support from solution providers. An open and flexible ethos sits as an important pillar of our solutions because no business really goes it alone.

With modern products including a greater mixture of mechanical, electrical, electronic and software systems, it is important to use a solution that can understand the interconnects between them the multitudes of subsystems they can encompass. Standardizing on an improved and open modeling language will provide a much more effective avenue for communicating the complex designs and ideas that lay inside tomorrow’s products. For more information on Siemens Software’s commitment to the development and adoption of SysML v2, it would be wise to read the co-authored piece from Nand and Dale. But for more information on the Siemens MBSE solution in general, our hub page is a great place to start.

To read about Siemens Software’s commitment to SysML v2, there is a great blog co-authored by Nand Kochhar and Dale Tutt – the industry heads of Automotive & Transportation and Aerospace & Defense, respectively.

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – Where today meets tomorrow