What´s New in Plant Simulation 2201?

The day before the Realize LIVE Europe conference, at the Plant Simulation User Day 2022 in Berlin, Dr Georg Piepenbrock, Product Manager for Tecnomatix Plant Simulation at Siemens Digital Industry Software, answered this question with an overview of features and functions in two major areas: PLM collaboration and material flow simulation core objects, including a hybrid SaaS solution and HTC VR support.

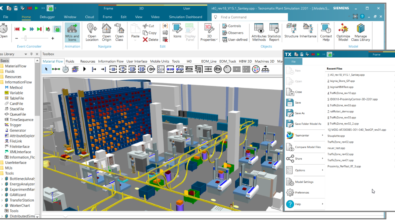

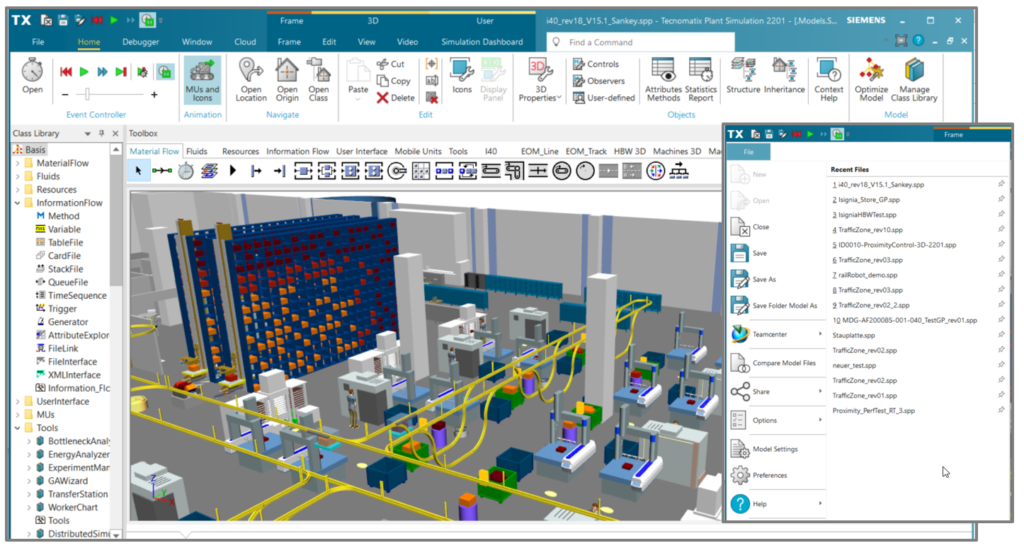

The first innovation is hard to overlook: Plant Simulation Version 2201 comes with a fresh-up of the graphical user interface, using the same color scheme and aligned icons as other manufacturing tools of Siemens´ Xcelerate portfolio. Thus Plant Simulation users will feel immediately at home when recognizing the graphical user interface. This speeds up the learning curves and facilitates switching between multiple software solutions.

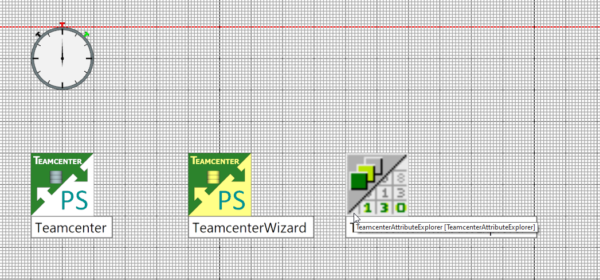

Enabling PLM Collaboration

Siemens implements many seamless PLM workflows through planning and engineering. It improves data sharing and reuse of PLM contexts based on the Teamcenter Wizard. Another functional enhancement in the PLM collaboration is the PLMXML import of kinematic models of manufacturing objects to Plant Simulation. This also allows reusing kinematic models, which already exist e.g. in Line Designer – factory design and simulation. Compare the short video, that shows how to use imported joints for defining individual poses. This works with the kinematic functionality already available in Plant Simulation 3D.

For the Teamcenter interface, Siemens introduced an enhanced data file security level. Activating the security setting on the Teamcenter Server removes all related files from the local computer.

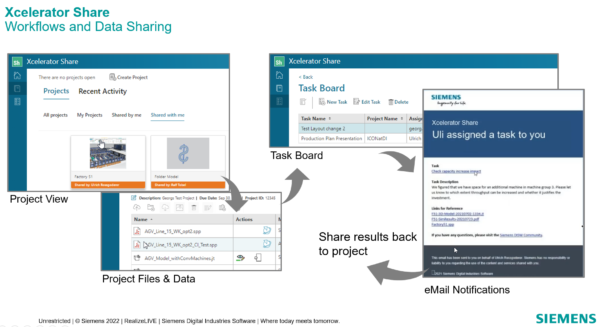

Hybrid SaaS Advantages

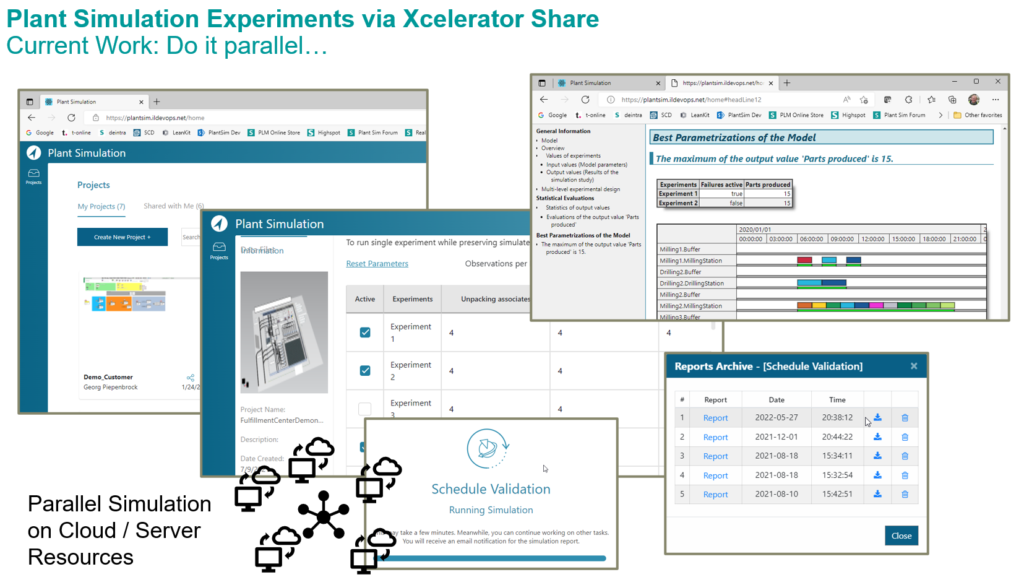

Hybrid SaaS further improves PLM collaboration with Plant Simulation. This option provides access to the Teamcenter Share platform. Users can share simulation-related data, simulation models and results via the Teamcenter Share web platform. This also supports checking simulation models, that are saved to Teamcenter Share, in and out. This enables Plant Simulation user groups inside of a company and even guests from the extended enterprise to take advantage of the built-in collaboration and sharing functionality allowing them to work on specific models in parallel without interferences.

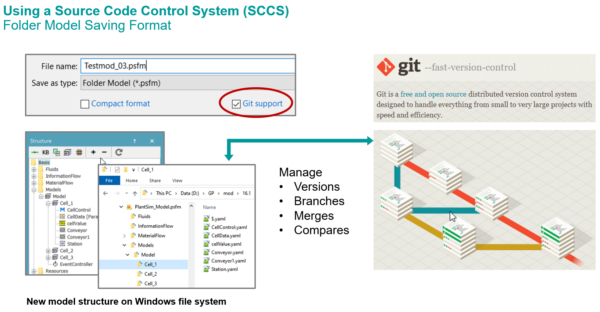

Material Flow Simulation

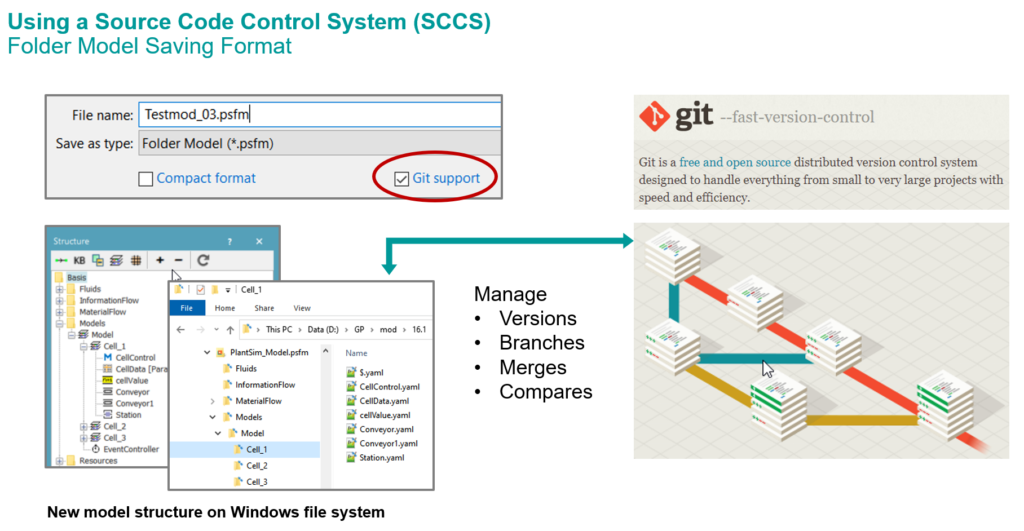

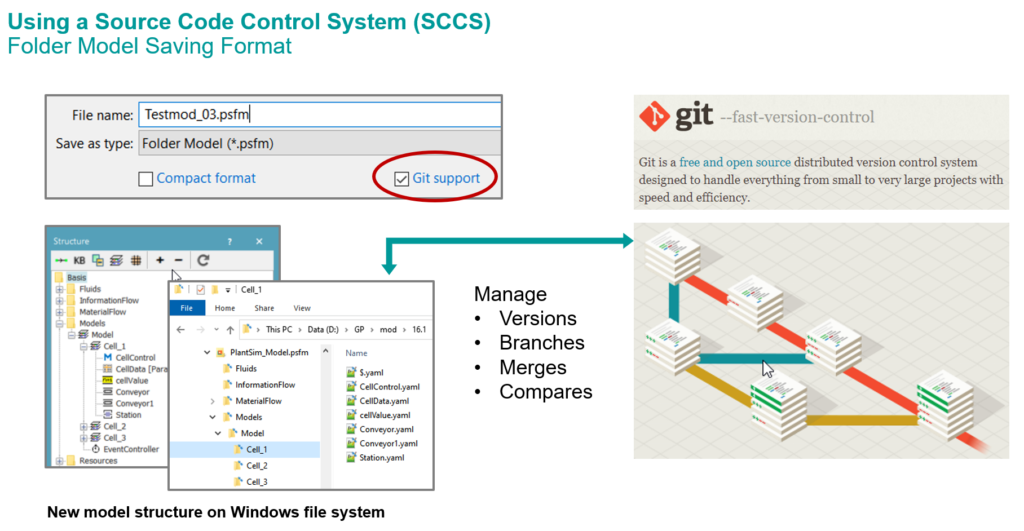

Another development focus added several enhancements extending the material flow simulation capabilities. Development teams can use a text-based saving pattern, that enables model management and versioning in regular Source Code Control Systems (SCCS), such as Git. With this milestone, simulation engineering teams benefit from and use state-of-the-art functionality in software development.

AGV Proximity Control

Two safety zones, added to the freely driving Transporter, allow to easily specify transporter actions. A typical example is stopping a transporter behind a waiting one at a loading position. Another task would be reducing the transporter speed in two-way traffic systems. This is accomplished by a SimTalk method, that is called, once another transporter enters or leaves the safety zone.

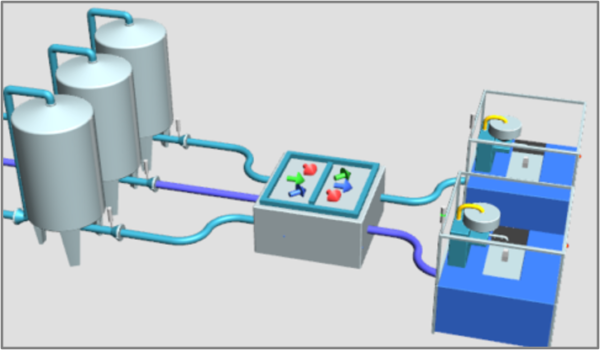

Patch Matrix for Fluid Pipes

Some time ago, Plant Simulation introduced simulation objects for batch handling and fluid processing. Plant Simulation 2201 adds the PatchMatrix object, simplifying model design for fluid manufacturing processes. The PatchMatrix supports production program changes requiring multiple piping connections or changes between fluid tanks and filling stations.

MQTT Support for AGV Fleet Control

Message Queuing Telemetry Transfer (MQTT) is a widely used message broker system. It is regarded as one of the most important communication platforms for the Internet of Things. Plant Simulation supports MQTT to connect simulation models to external control systems. A good example is a AGV Fleet Manager – with a connection allowing to run and test the external control against the virtual AGV system.

Virtual Reality with Head-Mounted Displays

Head-mounted displays (HMD) offer a simple and cost-effective way to explore simulation models in Virtual Reality (VR). In the past, this required an additional viewing system, adding complexity to the process. Version 2201 of Tecnomatix Plant Simulation simply allows to use the HTC Vive head mounted display to walk through and inspect running simulations in VR. A surprising experience, that many customers will soon add to their demo centers, to share it with potential and existing customers!