Webinar: EV Manufacturing Challenges Solved

EDAG and Siemens are moving electric vehicle production into the fast lane with a digital twin of process and production

—–

Learn how to get started on your EV manufacturing journey.

The automotive industry is going through a massive change. Many governments across the globe are trying to reduce automotive tail pipe emissions. At the same time, technological progress is increasing battery capacity to hold more charge. Both are converging to realize mass production of electrically powered vehicles.

Existing automotive original equipment manufacturers (OEMs) want to hold on to market share as they begin to produce electric vehicles. New entrants (EV startups) seeking business in the automotive industry expect a sea-change in the business model for monetizing vehicles. Suppliers must evolve their business by investing in new technologies for electrified powertrains and batteries while maintaining current production.

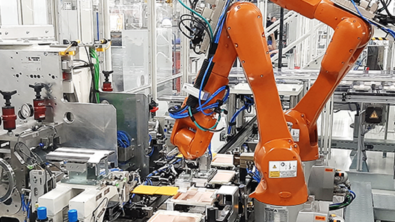

EDAG is an engineering expert in e-mobility solutions. They know that to succeed, OEMs and suppliers must overcome technical challenges related to lightweighting, battery manufacturing, and platform planning. To do so, EDAG and its partners, Baomarc and Cloos, leverage Siemens software for additive manufacturing, process simulation and validation, line design and optimization, and manufacturing process planning. By doing so, they are better able to evaluate both strategic and tactical EV manufacturing investment decisions.

> Watch this webinar to learn how EDAG and Siemens solve tomorrow’s EV manufacturing challenges today.

—–

Presenters:

Christian Teppich, Body Engineering Project Leader, EDAG Engineering

Timur Ucan, Business Development, Siemens Digital Industries Software

![Supercharge battery module manufacturing with Process Simulate software [WEBINAR]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/09/battery-module-mfg-webinar-395x222.png)