Standardization drives fast, smart, and easy scaling of logistics simulation with a factory simulation library

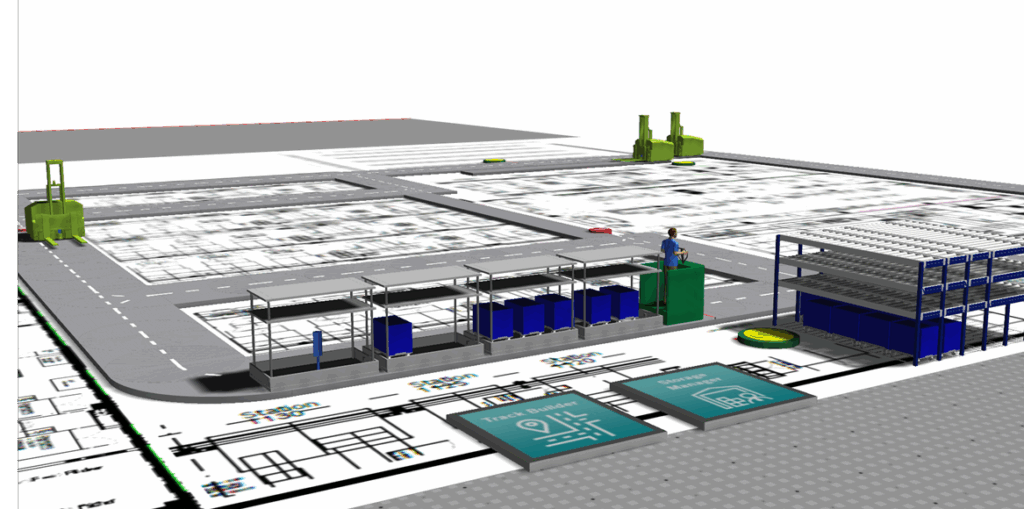

Standardization is essential in the age of Industry 4.0, where agility, speed, and data-driven decision-making define competitiveness, and logistics systems must evolve faster than ever. One of the most powerful tools available to logistics engineers and planners is simulation—the ability to model, test, and optimize processes in a virtual environment before implementation. A key advancement in this area is the use of the Digital Twin of production, which creates a dynamic, real-time virtual replica of physical processes. This allows for continuous monitoring, analysis, and optimization, bridging the gap between the virtual and real worlds. However, as invaluable as simulation and the Digital Twin of production are, they often remain underutilized due to one persistent challenge: complexity.

Creating accurate simulation models is essential, but in many organizations, the time, expertise, and resource demands have kept simulation limited to a few experts or isolated use cases. But what if simulation could be democratized — made fast, smart, and easy for teams across the enterprise?

Enter the Bosch Factory Simulation Library

Bosch has developed a solution that addresses this very problem: the Bosch Factory Simulation Library. This innovative tool redefines the way simulation models are created and scaled by introducing standardization at the core of the modeling process.

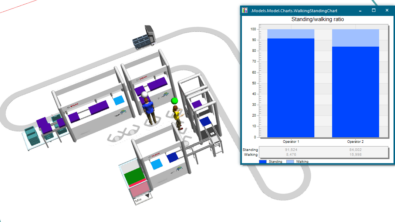

The Bosch Factory Simulation Library is a collection of pre-built, standardized objects tailored for manufacturing and logistics simulation. These objects encapsulate best practices and proven logic, drastically reducing the need for custom code and model-specific development. By focusing on reuse and simplification, the library significantly lowers the entry barrier for new users while speeding up the work of experienced modelers.

2025 Plant Simulation User Conference

As part of the 2025 Plant Simulation User Conference at Realize LIVE, Amsterdam July 2nd, we are pleased to welcome Carsten Meyer as a speaker. With his extensive experience in material flow simulation and as the driving force behind the development of the Bosch Factory Simulation Library, he will share valuable insights into how standardization and smart approaches can take the use of Plant Simulation to the next level. Standardization plays a crucial role in enabling faster model creation and ensuring consistent quality across simulation projects. By leveraging standardized components, organizations can significantly reduce complexity and accelerate the scaling of logistics simulations. To date, he has successfully led simulation projects at 17 plants across eight divisions of Bosch. Tune in to experience a practical presentation that demonstrates how simulation can truly become fast, smart, and easy.

Carsten Meyer studied Industrial Engineering at HTW Aalen and EAH Jena before joining Bosch in 2017, where he initially developed a bespoke video‐analysis software solution for the Eisenach plant. In 2018 he transitioned into the Corporate Manufacturing Services department as a Material Flow Simulation Specialist, and since 2019 has played a key role in the Power Solutions division’s “Digital Production” working group, shaping training curricula and best‐practice standards. In 2022 Carsten spearheaded the creation of the Bosch Factory Simulation Library for Plant Simulation—a standardized toolkit now deployed across the entire Bosch organization.

Fast: Modeling at the Speed of Standards

Traditionally, modeling a logistics system could take days or even weeks. With standardized library components, that timeline can be cut dramatically. Instead of starting from scratch, users can drag-and-drop tested, reliable objects into their model and begin analyzing performance right away.

For example, instead of programming an AGV logic from zero, a user can configure a standardized module in minutes. This approach doesn’t just save time; it ensures consistency across models and projects.

Smart: Semi-Automation for Efficient Modeling

The Bosch Factory Simulation Library goes beyond drag-and-drop. It includes smart features like semi-automated model creation, where data inputs can be used to generate large parts of a simulation model automatically. This greatly reduces the need for manual data entry and repetitive tasks, freeing engineers to focus on analysis and decision-making.

Fast, Smart, Easy: Scaling logistics simulation by standardization

Carsten Meyer

Incorporating automation in the modeling process also enhances scalability. Large or complex systems that once required extensive custom development can now be built and adjusted rapidly with minimal additional effort.

Easy: Gamification and User-Friendly Design

Simulation shouldn’t be confined to a handful of specialists. The Bosch Factory Simulation Library is designed with usability in mind. It leverages gamification principles to make modeling intuitive and engaging—turning what used to be a technical chore into a creative and interactive experience.

From guided configuration dialogs to visual feedback and integrated help, every element is built to support both novice and expert users. The result is a tool that not only accelerates model development but encourages wider adoption across departments and roles.

By making simulation fast, smart, and easy, the Bosch Factory Simulation Library helps organizations scale their simulation efforts with confidence. Standardization not only improves speed and consistency—it unlocks new levels of efficiency and accessibility, empowering teams to optimize logistics systems proactively and effectively.

In the world of Industry 4.0, the ability to simulate is no longer optional.

Join the 2025 Plant Simulation User Conference

The 2025 Plant Simulation User Conference will take place on Wednesday, July 2, 2025, as part of Realize LIVE Europe in Amsterdam, and is specifically tailored for users of Siemens Tecnomatix Plant Simulation. The event will be held at the RAI Convention Centre, starting at 9:00 AM (doors open at 8:00 AM), and will conclude around 6:00 PM with a joint Q&A session. Attendees can either purchase a dedicated one-day pass for the Plant Simulation track or take advantage of the full Realize LIVE program from June 30 to July 2.

The conference will feature two parallel presentation tracks, with a strong focus on discrete-event simulation, real-world industry applications, and the latest product developments. Key topics include material flow optimization, Python integration for modeling, flexible manufacturing strategies, and AI-driven simulation methods. The event also emphasizes direct engagement with Siemens experts and peer users from across various industries.

As part of the broader Realize LIVE Europe program, attendees will have access to over 350 sessions, including practical presentations, hands-on workshops, certification opportunities, and insights into related topics such as Tecnomatix, Opcenter, Simcenter, and Mendix.

Participants of the Plant Simulation User Conference will benefit not only from deep technical content but also from extensive networking opportunities with more than 1,200 professionals and experts. The event provides a unique platform to engage directly with Siemens product developers, discuss specific simulation challenges, and gain valuable inspiration for enhancing simulation practices within their organizations.

The full session catalog for Realize LIVE Europe 2025 is available here:

👉 Session Catalog

Register Now

Don’t miss your chance to be part of the 2025 Plant Simulation User Conference at Realize LIVE Europe in Amsterdam! Whether you’re looking to deepen your simulation expertise, connect with industry peers, or explore the latest developments in Plant Simulation, this is the place to be.

Secure your spot today by registering through the official event portal:

👉 Register Here

Seats are limited—register today!