Providing full digital access to an innovation campus

Intosite connectivity supports ongoing research, education, and business efforts at Brainport Industries

Brainport Eindhoven, The Netherlands, is a complete tech ecosystem of OEMs, small and medium enterprises (SMEs), manufacturers, and knowledge institutes – and it is growing. A key element of Brainport Einhoven is the Brainport Industries Campus (BIC), which officially opened in 2019 with its first of five factories of the future – a 100,000 square-meter working and learning facility. BIC is designed to enable close cooperation within a community of thinkers and producers, who work together on a range of manufacturing innovation efforts. Since Brainport is fitted with technical infrastructure shared in an open innovation setting, it only makes sense for such a robust technology center to be supported by full digital visibility and connectivity. Siemens Intosite™ software is providing this full digital access.

At Realize LIVE 2021, Siemens’ global customer event, Brainport and Siemens team members described how Intosite is benefitting researchers, students, and visitors, and they presented plans for future with Intosite applications. This blog summarizes the presentation.

The innovation challenge

The Brainport Industries Campus grew out of the city of Eindhoven’s paradigm of “open innovation,” which BIC describes as “a unique way of collaborating, focusing on integrated ideas and operating in ad hoc formations. Open innovation is based on trust, loyalty, motivation, and passion.” BIC provides essential tools and infrastructure to support open innovation. The campus includes shared facilities such as flexible production areas, warehouses, and offices. It also enables partners within the same supply chain to work under the same roof, which eliminates all the logistics and costs of moving semi-finished parts from one facility to another. Instead, smart logistics at Brainport move parts and materials via automated guided vehicles (AGVs), robots, and other automated systems. Shared outbound logistics consolidate shipping and delivery expenditures.

As a technology center, Brainport Industries Campus provides a physical location in which innovation and education can take place; but this leaves open the question of access for those not physically on campus. BIC needs to provide not only virtual visitor tours, but also detailed, accurate, and up-to-date information about the facilities and equipment available to offsite educators, innovators, and producers – including accurate visualization of all assets. While this need was always apparent to BIC management, it became abundantly clear from the outset of the COVID pandemic. “During COVID, we don’t have so much traffic as usual, so we have to go digital and online,” says Michel Weeda, innovation manager for BIC.

Virtual field laboratories

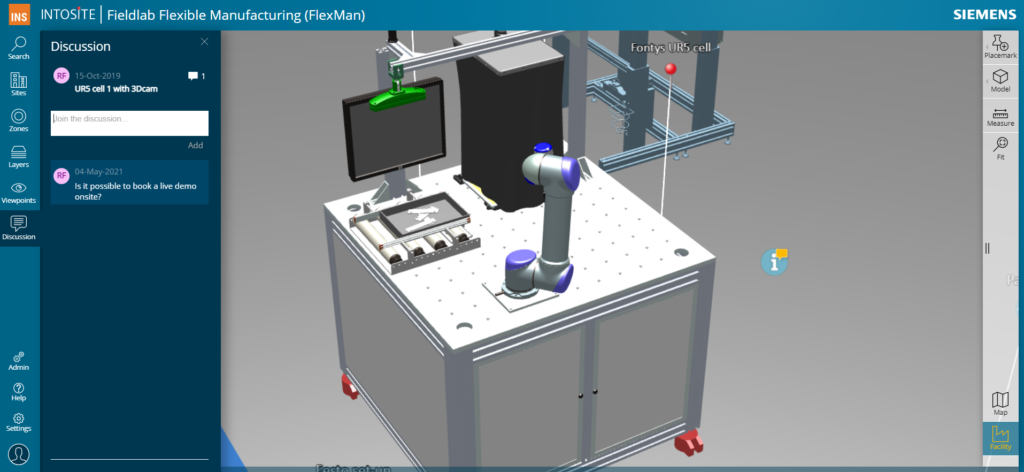

Siemens Intosite is meeting BIC’s need for remote access to an accurate, up-to-date digital twin of each of BIC’s six field laboratories. Intosite is a cloud-native, zero-install web solution that opens virtual access to information in a digitally reproduced, visual context of a facility. Intosite provides 2D, 3D, and panoramic representation that enables stakeholders to navigate virtually within a digital twin of a facility, in a way analogous to a Google street view experience but with greater detail and accuracy and linking to engineering and enterprise data. “It allows you to navigate through a facility in a simple and familiar way, and to get to relevant information by simply clicking on visual tags,” says Piet van Dongen, business development manager at Siemens. “Intosite’s fundamentals are visualization, information, and collaboration.”

With Intosite managing the data and images associated with each field lab, stakeholders can access a single, up-to-date copy of the information from anywhere around the globe. When changes are made, the new information can be automatically uploaded to Intosite.

Brainport Industries Campus is using Intosite in several beneficial ways, one of which is to provide a virtual introduction to BIC operations. “We use Intosite to organize virtual tours to show what kind of facilities we have on this campus, what kind of equipment,” Weeda explains, “to show the world outside. If you are not physically here, you still can have an impression of what is going on.” Within each digital twin, Intosite provides access both to an accurate 3D digital model and to an actual image rendered from panoramic pictures captured onsite. Users can use street view navigation to make their way through each lab.

The depth of information available on Intosite extends well beyond what is used in a general tour. Zooming in on a particular machine within one of BIC’s field labs, for example, an Intosite user will see placemarks, or floating icons; clicking on a placemark provides access to whatever information the facility owner wishes to share: presentations, documents, videos, links to external websites, live data via MindSphere®, the industrial IoT as a service solution from Siemens, and more. Siemens also designed the BIC Intosite implementation to foster interaction and cooperation. “We wanted to bring each of those labs together on the same platform,” says Rui Feio, presales solutions consultant at Siemens, “so that they could not only have the digital twins in an online platform, readily available, but also so that they could collaborate with each other.” Each lab is managed independently in Intosite, though, which enables regular updating of the lab’s information, machine types and models, showcases, and more.

More connectivity to come

As a single, accessible, and up-to-date information source, Intosite is helping make Brainport Industries a kind of borderless campus. Weeda foresees ongoing growth in the virtual access and visibility that Intosite provides, in two ways. “First is to integrate process flow, to show how a product is evolving from design up to an end product – to show that in a virtual way and to combine that with how it is happening on this campus in the real world. Second, besides the virtualization of what’s here, we are making the connection to the next level, getting into IIoT and the data level of the equipment we have here.”

“Intosite for our field labs and innovation activities is a perfect tool,” Weeda concludes.

—–