Process Simulate helps SGAR reduce project time by 30 percent

Overview

SGAR is an engineering and industrial automation company specializing in software design, programmable logic controllers, robot programming and hardware engineering, but mainly provides programming, validation, and implementation of production-line services. With the implementation of Tecnomatix Process Simulate software, SGAR has enhanced productivity, profitability, competitiveness, and reduced project time by 30 percent.

Problem

SGAR was challenged with being able to work in all kinds of facilities regardless of the systems and robot models required by the customer. They also must deliver results with maximum precision and quality, while reducing time and cost to increase business productivity.

Epiphany

The company’s commitment is to be more competitive, provide high quality service, work with PLM products and introduce themselves to the world of virtual manufacturing.

To achieve these objectives, they realized they realized the need for a robust 3D tool for the simulation, optimization, validation, and scheduling of processes for robotic and automated manufacturing.

Execution

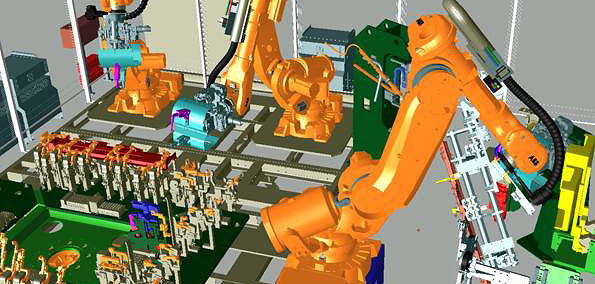

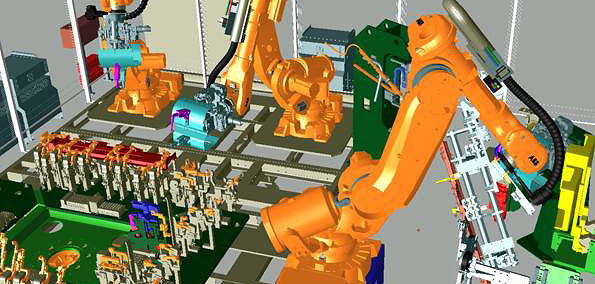

Robcad was the first Siemens software solution implemented by SGAR because of its advance capabilities, its’ fit with their business model, and the ability to meet customer needs. In recent years they migrated to Process Simulate software. The use of Robcad and Process Simulate provides SGAR with a virtual environment, advanced tools to validate the data provided by the mechanical supplier and the ability to completely simulate manufacturing environments. Process Simulate has two modules that have been critical for optimizing SGAR’s work: robotics and virtual commissioning. Robotics allows for offline programming of robots and includes two utilities that allow for project optimization. Virtual commissioning allows for the debugging of PLC code in a virtual environment before downloading it onto the actual equipment.

Results

Process Simulate enables the validation of weld points. It used to take the company a lot of time to perform the functions step by step and then wait for the test, but they are now able to the compete the work easily with excellent results. Because of the advanced capabilities and the use of more modern architecture, they can mark one piece and set the equipment to weld 100 points all at once. A task that used to take half a day to execute is now performed in 30 minutes.

Process Simulate enables the validation of weld points. It used to take the company a lot of time to perform the functions step by step and then wait for the test, but they are now able to the compete the work easily with excellent results. Because of the advanced capabilities and the use of more modern architecture, they can mark one piece and set the equipment to weld 100 points all at once. A task that used to take half a day to execute is now performed in 30 minutes.

Process Simulate allows SGAR to better generate and manage documentation for clients through the lifecycle of the project.They can now deliver details in a very simple manner: if they find errors in a mechanical assessment, aspects that are not validated, comments, etc. it allows for the maximum communication of this information with tools to create ad hoc snapshots, and 2D/3D videos with editing support.

The use of rocess Simulate has made the company more competitive due to its agility and speed, providing new capabilities and improvements. It is these characteristics that allow the robotic simulation team to take on difficult projects. With Process Simulate it takes SGAR 30 percent less time to carry out a project, they are able to do work that they could not do before, and have developed the know-how that sets them apart in the market. SGAR can now anticipate changes that need to be made before anything goes to the production line. This advantage directly affects their costs and the client’s final costs, and results in customer satisfaction and loyalty.

To learn more about how SGAR uses and benefits from Robcad and Process Simulate, read the complete case study.