Must See Tecnomatix Sessions @ Realize LIVE

Looking for mind-expanding presentations by industry leaders? Tecnomatix @ Realize LIVE featured sessions bring together some of the biggest and brightest names of our industry. Spanning various themes and trends, view a snapshot of the most transformative ideas shaping our future.

Register now and claim your complimentary pass!

Tuesday, June 23

12:30 PM – 1:10 PM EDT / 9:30 AM – 10:10 AM PDT (40 Min)

Xcelerator Portfolio Update

Rapid-Response Innovation in Manufacturing

Manufacturing is critical now more than ever. Rapid-response innovation is needed to address the complexity that industry faces today. And, by addressing this complexity, you gain a competitive advantage. You will hear from Zvi Feuer and his colleagues how Siemens software helps manufacturers effectively respond to today’s challenges and build innovative products using a comprehensive Digital Twin.

To properly maintain these innovative products, manufacturers must also integrate service operations into their processes using the comprehensive Digital Twin. This will provide the required asset-specific configuration and service requirements of the physical assets directly linked to all available engineering and manufacturing data. You will hear from Ӧlav Hjermann how service in product and production life cycles benefits manufacturing and maintenance operations at OneSubsea.

—–

1:10 PM – 1:30 PM EDT / 10:10 AM – 10:30 AM PDT (20 Min)

Q&A for Xcelerator Portfolio Update Sessions

—–

2:10 PM – 2:30 PM EDT / 11:10 AM – 11:30 AM PDT (20 Min)

Breakout #2

Integrated robotics and assembly planning at BSH for higher process efficiency

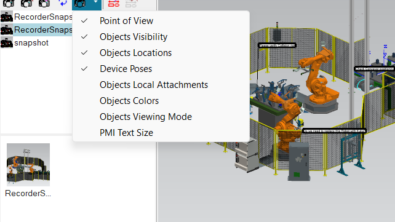

BSH is one of the leading home appliance manufacturers worldwide. Being number three globally and number one in Europe, BSH operates 44 factories around the globe. The PLM strategy of BSH includes an integrated Digital Factory approach, based on the Teamcenter Manufacturing backbone, as well as value added applications like Tecnomatix Process Simulate on Teamcenter for robotics automation planning, and Active Workspace based Easy Plan for assembly planning, ergonomics evaluation and line balancing for assembly lines.

These applications run entirely on top of Teamcenter Manufacturing thus allowing all Manufacturing Engineers in BSH to reuse Engineering data such as factory layouts, bill of material and bill of processes, to efficiently plan their production. This presentation will highlight the strategy for the integrated Digital Factory at BSH, which incorporates all relevant Manufacturing Engineering disciplines. BSH Digital Factory goal is to raise overall engineering efficiency and productivity as well as to deliver detailed plan of production facilities and processes, as early as possible to reach start of production with highly mature and well proven production processes.

—–

2:30 PM – 2:50 PM EDT / 11:30 AM – 11:50 AM PDT (20 Min)

Wednesday, June 24

12:50 PM – 1:10 PM EDT / 9:50 AM – 10:10 AM PDT (20 Min)

Breakout #4

Innovate Service Business by SLM

Service Lifecycle Management (SLM) is the practice of aligning service parts management, technical communication, field service management and product support operations to maximize customer assets. SLM @ PLM enables service organizations to manage all the service aspects of a product from design phases until it is no longer in service. A complete SLM process drives up efficiency effectivity of all aspects of service operations.

Siemens Energy hast started a Teamcenter implementation of an SLM “Gearbox” which will significantly improve the Service Lifecycle process. This session outlines the approach, current status, initial benefits, and the future roadmap.

—–

1:10 PM – 1:30 PM EDT / 10:10 AM – 10:30 AM PDT (20 Min)

—–

1:50 PM – 2:10 PM EDT / 10:50 AM – 11:10 AM PDT (20 Min)

Breakout #5

3D Material Flow Simulation in the Metal Manufacturing Industry

Today’s manufacturing industry is coping with an increasing variety and complexity. 3D material flow simulation offers significant benefits to visualize the whole manufacturing processes and manage the complexity. This presentation will show how Plant Simulation is used at EMAG to visualize and analyze the manufacturing line in the metal processing industry. It covers the 3D-Animation of moveable components and the evaluation of production line performance using an internal developed simulation tool kit. The experiences, quick wins and limitations will also be shared in this presentation.

—–

2:30 PM – 2:50 PM EDT / 11:30 AM – 11:50 AM PDT (20 Min)

Register now

Learn more about our presence at Realize LIVE on the Digital Manufacturing Experience page.