Integrated design & simulation for optimizing design solutions

This video blog was co-authored by Zvi Feuer and Paul Boes, Siemens Digital Industries Software.

Join us at the second station on the Digital Enterprise Factory Showcase Tour – Mechanical Design and Analysis. During this stop on the tour, we integrate a new hardware component to our high end field PG. We need to make sure that our design changes are not generating any issues like overheating. Your tour guide describes integrated design and simulation for optimizing design solutions featuring NX CAD and Simcenter 3D. The video highlights the capabilities of the Siemens solution, including:

-

- Seamless workflow between design and simulation

-

- Fast, rapid, easy to use design tools for design and design changes

-

- Fast optimization tools for simulation

-

- Multi-CAD support for design and simulation

What do you think of the video blog? You can leave a comment below or contact the team directly by using the address: df_showcase.plm@siemens.com

Transcript of the Mechanical Design & Analysis video, narrated by Paul Boes.

Welcome to the mechanical design station.

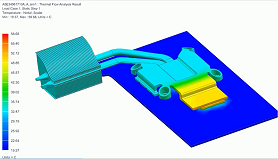

Here we are integrating new hardware components to our high end field pg. For this demonstration we will start with a multi – physics coupled analysis used in thermal end flow of heat on the main circuit board and finishing by making some design changes to handle the increased airflow needs.

Technologies and electronics is still processing rapidly, higher performance and smaller packages is the norm. Heat dissipation or making sure electronic devices do not over heat is critical to an electronic OEM. Here we can quickly and accurately model complex heat transfer problems in a virtual environment.

Here we will investigate a problem with multi physics components. In this case, fluid flow and heat transfer. Using an integrated solution for our CAE and design geometry allows us to create mesh boundary conditions and material attributes that are geometrically dependent. This will save the CAE analyst work by not having to re-do his or her job if the design has changed, and an iteration of the solution is required later in the process.

Our integrated solution allows the CAE analyst to generate accurate results for complex problems in one environment.

Here we are modeling the heat flow that is being generated by the GPU and the CPU inside the laptop. Heat will transfer via convection and radiation to the neighboring components and environment. Meanwhile the effects of the fan and several cooling fins are included by determining the effect of airflow from the fan to the fin. Now we will increase the size of the cooling bracket to accommodate the new hardware chip we are using. By reusing the existing geometry from an older design, or a foreign CAD system, we can simply modify the geometry by moving the faces to the desired location or position.

As you can see, we have changed the complex shape that has many CAD features quickly and easily.

As a designer, we need to author and change complex shapes on a regular basis. You can see by moving the feature that was created in a foreign CAD system it is easy with our solutions. Something that took hours before to change, is now done in minutes. Now that we changed the bracket for a larger CPU and GPU component, we need to address the cooling exhaust to allow additional airflow to exit the housing to keep the components within spec for under normal operation conditions.

The last step that we will perform, will be a simple copy of faces to add an additional exhaust port on the grill. By having an integrated solution for simulation and design, we can do more design iterations to have an optimized solution for our cooling needs. We can perform additional simulations like a CMD for the next iteration in the design cycle. By doing this we will continue optimizing and tuning our solution. This video demonstrates a tightly integrated simulation and design solution offered by Siemens PLM.

You can find video blog #1 from the Digital Enterprise Factory Showcase tour here.

Subscribe to the blog so you don’t miss any of the posts about the video blog series.

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)

Comments