Ingemat: a virtual commissioning success story

Automotive engineering company uses Tecnomatix virtual commissioning software to better meet customer requirements while driving operational efficiency.

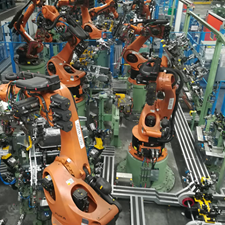

Ingemat is a Spanish engineering company offering robotic automation services for different industrial sectors, specializing in turnkey, tailor-made projects for the automotive industry. Their services cover installation design, erection, assembly, and commissioning to achieve the customer’s requirements for cycle time and quality. The primary technologies used in their projects include welding, hemming, bonding, clinching, and riveting.

Why Ingemat adopted virtual commissioning technology

Designing, deploying, and constructing a production line has always been based on a sequential process— The fixture installation is followed by robot installation and ensuring smooth operation with the equipment. Then, equipment and robots are integrated with programmable logic controller (PLC) automation until a qualified prototype can be produced.

But this waterfall process is time-consuming and costly, involving massive robot and control code debugging and dealing with physical installation and cabling and wiring issues. It also requires using several expensive prototype assets that are not always available on time. This makes engineers perform under restrictive time constraints and high-stress levels, especially in the automotive space, where high-quality standards are imposed.

The high standards of the automotive industry require Ingemat to work efficiently with as few errors as possible to meet timing and cost milestones. Because of this, they adopted Process Simulate in the Tecnomatix® portfolio of digital manufacturing software for robotics simulation and virtual commissioning.

“I would say, based on experience acquired in recent years, the selection of Process Simulate as a tool for virtual commissioning has been the right choice.“

Oscar Vázquez, Electrical Engineering Deputy Manager at Ingemat

Process Simulate helps Ingemat drive operational efficiency

Projects at Ingemat start with mechanical design and simulation, while electrical design progresses in parallel. After completing or advancing the mechanical design and simulation to a mature stage, offline robot programming (OLP) and PLC programming will kick off, followed by virtual commissioning.

Using Process Simulate, Ingemat has realized virtual commissioning projects with different robot brands such as ABB, KUKA, Fanuc, Yaskawa, and Kawasaki – all this in connection with PLCs issued from Siemens and Allen‑Bradley, as well as custom-defined hardware.

This methodology using Process Simulate allows Ingemat to parallelize work and shift most of the engineering tasks to the left in the project timeline, performing them in the back office.

Enabling mechanical, robotics, and controls departments to collaborate in the same platform allows the robot programs and the automation control code for PLCs and human-machine interfaces (HMIs) to be validated in the virtual environment before their delivery to the shop floor.

As a result, the physical commissioning phase is much shorter and more efficient, requiring less debugging effort and fewer prototype assets, allowing the virtual commissioning personnel to focus on the quality of the produced assembly rather than the debugging of program code.

Why Process Simulate was the right choice for Ingemat

In a typical project, Ingemat implements virtual commissioning on a robotic zone, including up to 10 robots performing various tasks.

Once the virtual commissioning technician sets the engineering environment, it takes 2 to 3 weeks to test the production scenario and finish the virtual commissioning phase via the collaboration between the PLC and robot programmers.

Consequently, robot programs and PLC codes are validated in the virtual environment and are already in a mature state when reaching the shop floor for the first time, leading to the following:

- 90% line readiness before physical implementation

- 40% reduction in on-site debugging time

- 10% savings in overall cost

In conclusion, the virtual commissioning team at Ingemat is delighted about their collaboration with Siemens. Process Simulate software has been the right choice to realize virtual commissioning for them and their customers.

More about Ingemat

With more than 30 years of experience and references with over 80 customers from multiple sectors, Ingemat offers services in Europe, Asia, the Americas, and Africa. While the headquarters is based in Spain, Ingemat has a subsidiary in Mexico and sales and after-sales services in China and Mercosur. Having delivered over 600 hemming systems worldwide since its founding, Ingemat has become an international benchmark within the automotive market.