How THK Manufacturing of America uses Plant Simulation to Optimize Manufacturing

How THK Simulation cannot only help with analysis and optimization, but also with execution. This customer example, based on a presentation at the Plant Simulation Users Day 2022 in Berlin, pulls its astonishing results from feeding simulation data into a customer-specific manufacturing system. THK Manufacturing of America uses Siemens Digital Industries Software Tecnomatix Plant Simulation to Optimize Manufacturing.

Challenges and Solution

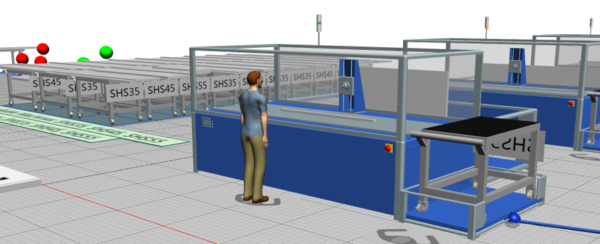

Digitalization is considered a global transformation challenge for companies. This leads directly to new business models. But down on the shopfloor, this overall change consists of hundreds of processes, which can be optimized with the help of digital means. This is exactly what Daniel Abdelsamed did. Daniel seized the opportunity to start of a new digitalization team, in short DX team, at THK Manufacturing of America, a global manufacturer with about 13.000 employees all over the world, to introduce Industry 4.0 at THK Manufacturing of America.

THK Manufacturing of America, Inc. is located in Hebron, Ohio. It is part of the Navigational, Measuring, Electromedical, and Control Instruments Manufacturing Industry which has 160 total employees across all of its locations. THK of America produces linear guides, machine elements that utilize bearings. These are developed for rotary motion to move heavy objects easily and accurately in a straight line. The linear guide largely comprises three components: a mobile carriage, a rail that supports the movements of the carriage, and balls.

Starting with a Single Manufacturing Process

From the big picture of challenges related to manufacturing, the DX team started with the cutting process for the rails. Not only are THK’s rails fully customizable, but the cutting process can face dozens of different rail types and hundreds of SKUs in one day. Inventory consists of full-length stock and drop rail. Drop rail remains after several cuttings of stock rails, and is stored for further use. Both rails are released to saws, where customer-specific lengths are produced.

The DX team had two major targets: The first was to use more drop rail from the inventory. The second was to maximize the utilization of each rail. It is great to utilize drop rail, but not having it in the first place is even better.

By creating new algorithms to better pack as many orders into each rail, we wanted to maximize our utilization to increase overall process efficiency”

Daniel Abdelsamed.

Many Related Challenges

First and foremost, THK had to upgrade the inventory and warehouse release process. Understanding and allocating a constantly changing set of stock takes time and a significant amount of knowledge. The DX team also wanted to create cut plans for operators. Designing cut plans that balance optimization of drop loss, cut speed, order queue, and due date needs was complicated and required attention to multiple datasets. After this the results needed to be published intelligently. Smart data would need to be provided to schedulers, operators, managers, and warehouse employees, all stakeholders in the release process. THK chose different software to solve these problems and connected it to a single point of truth.

Tecnomatix Plant Simulation

To build a digital twin of the inventory, THK needed an adaptable and agile software. They found that Tecnomatix Plant Simulation from Siemens´ Xcelerator Portfolio was an adaptable and agile software to cover this.

Plant Simulation allowed us to custom program in everything we needed for an accurate digital twin of our cut process. To update our cut planning, we built a custom cut algorithm which harnesses GPU power to quickly optimize our cuts.”

Daniel Abdelsamed

THK Manufacturing of America then broke the Plant Simulation plan down into three major steps:

- Capture floor data to build an accurate model.

- Validate the simulation model to assure accuracy.

- Generate optimization parameters to allow the simulation to increase efficiency.

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)