Day 3 Highlights – Realize LIVE for Simulation Conference

The Realize LIVE for Simulation Conference (aka Plant Simulation Worldwide User Conference), October 15-17, 2019, was a great success. According to Matthias Heinicke, Business Lead Plant Simulation, 330 participants went home happy and inspired by the spirit of worldwide teamwork. The annual conference in Stuttgart, Germany, brought together Samsung from Korea, Electrolux from Sweden, and Rolex Switzerland with Lego Denmark and Swarovski. The final day of the conference wrapped up with a series of presentations delivered by partners, customers and Plant Simulation experts from Siemens. Read the highlights from day three of the conference:

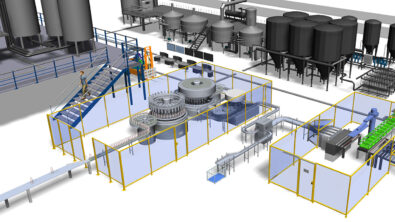

Large scale 3D Plant Simulation models used at SSI Schaefer in intralogistics – lessons learned

Presenter: Lars-Boris Bottcher, SSI Schäfer

For 6 years Lars-Boris Böttcher is responsible for the simulation and data analysis department of the SSI Schäfer Automation Group. His team is conducting simulation studies for all market sectors worldwide, evaluating and optimizing concepts in the field of intralogistics. Before he worked another 6 years as consultant and technical sales manager in the field of simulation and emulation. During his studies of computer science he already focused on simulation, writing his master thesis about simulation of supply chains at Volkswagen AG in 2008.

Presentation summary: Following a constant growth over the few last decades, simulation in intralogistics has experienced a surge within the last 3 years. This is due to an increasing size and complexity of systems and smarter solutions. Current discussions about AI and Digital Twin are amplifying this effect. Observing the market, different tools are competing in 3D animation, offering high quality 3D visualizations. Therefore, SSI Schäfer was using 2D simulation in addition to 3D animations. This changed due to the improved 3D capabilities of Plant Simulation software. SSI Schäfer is constantly expanding its 3D modeling, meanwhile running the largest and most complex studies with >250,000 simultaneously moving items in 3D.

During this talk Mr. Bottcher, shared experiences, limitations, concepts, quick wins and motivations in large scale 3D models. He also showed examples of large intra-logistics simulation models naming run-times, pitfalls and lessons learned.

Plant Simulation scheduling use cases in the Consumer-Packaged Goods Industry

Presenter: Stefan Pfaff, PPI-Informatik

Stefan Pfaff studied Production Engineering in Aalen, where during an intern he had contact with SIMPLE++, the predecessor of Plant Simulation. After two years at AESOP Consult, he co-founded PPI-Informatik together with three other colleagues in 1996. The focus of PPI is providing Simulation Consulting in production and logistics, where Stefan is involved in most of the projects related to production and optimization.

Presentation summary: PPI recently was involved in many projects focusing on Production scheduling. These projects for different manufactures of different products share a common problem to be solved. How to schedule the sequence of the production orders in a way to maximize throughput, without violation of the complex constraints and rules that define a valid schedule for the specific operation. In most cases the constraints are linked to complex rules for resource allocation or to avoid downtimes by minimizing cleaning and set up operations which result from the sequence the orders are processed during manufacturing.

Typically, these types of restrictions are difficult to handle for classical ERP-based scheduling tools. PPI showed how simulation-based Scheduling Tools based on a Plant Simulation process model and an Optimizer, which is also build with Plant Simulation, works. Several use cases illustrated the benefit of this Simulation-based Scheduling approach and gave an overview of how to approach these types of projects.

Modeling of worker impacts in automated body shop lines (approach and findings)

Presenter: Steffen Bangsow, Steffen Bangsow Advanced Simulation Services

Steffen Bangsow has been working with material flow simulation since 1999. He already used previous versions of Plant Simulation, such as Simple++ and eM-Plant. Since 2002 Mr. Bangsow has been in the business of factory planning e.g. for automated production lines. In addition, he is the author of several books on Plant Simulation in German and in English. Mr. Bangsow works as an independent contractor for discrete event simulation projects as well as an instructor. He is teaching Plant Simulation basic, advanced and customized training classes. In his role as Plant Simulation mentor, he officially received the title of Plant Simulation black belt, leading the list of Plant Simulation related articles with over 900 Kudos in the Plant Simulation forum.

Presentation summary: In order to model the impact of the workers on the throughput of a body shop line, both robots and workers must be modeled in detail with their processes. The presentation showed several approaches to do this.

• modeling of assembly (welding, riveting, folding, screwing…) and handling robots

• modeling of robots on rails (7th axis)

• modeling of workers

• linking of robot and worker processes (e.g. modeling of worker gates)

• impacts of workers: e.g. missing the gate open-times, delays in case of failures, “bridging” of buffers

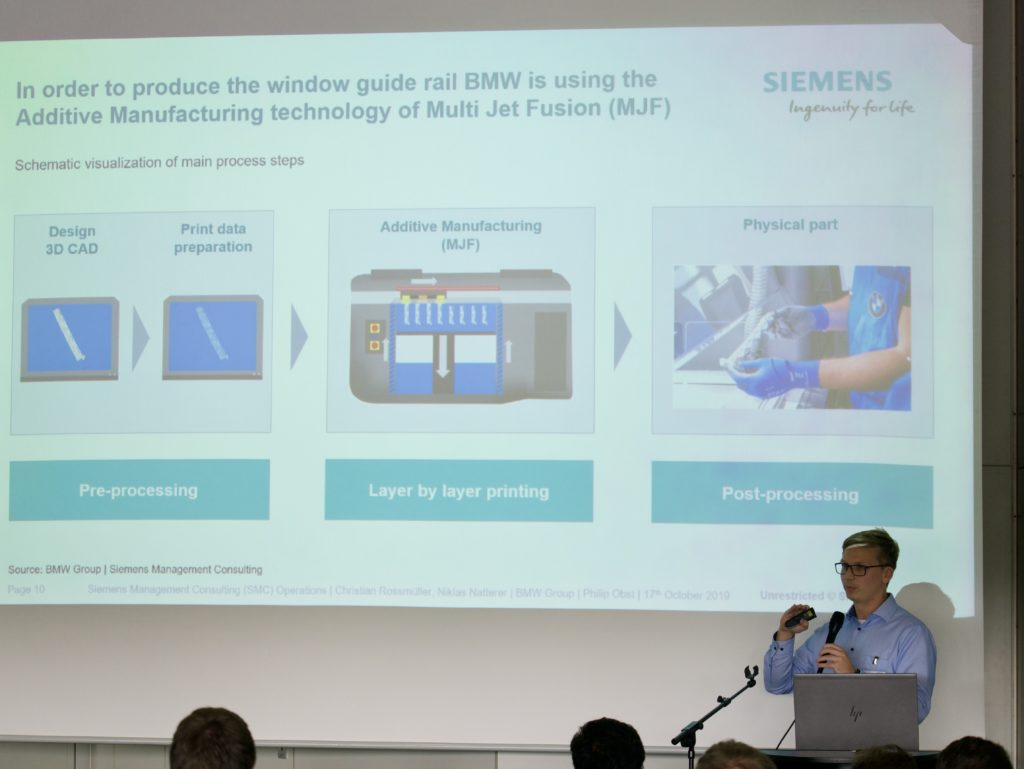

Digital Factory Planning for Additive Manufacturing in the automotive industry

Presenter: Niklas Natterer, Siemens AG

Niklas Natterer studied International Production Engineering and Management at the university of Erlangen-Nuremberg. He started his career as Consultant for Plant Simulation and Line Designer at Siemens PLM. In his current position, as Consultant at Siemens Management Consulting (SMC) Operations, he is focusing on the topics – digital factory planning and industrialization of additive manufacturing.

Presentation summary: Looking at the processes of additives production, so you quickly realize that the printing process itself represents the bottleneck of the production. Due to long printing times, the upstream and downstream, mostly manual, processes are at first glance irrelevant.

But since the printing process itself can be well parallelized and current machines can be easily automated, this raises the question of the ideal production line. As there are currently few simulation studies for AM, it was decided that cooperation between Siemens and the Additive Manufacturing Center should be promoted at the BMW Group. The aim of the cooperation was to gain experience based on two examples, such as a tool set for the simulation of AM. additive manufacturing.

3D Simulation of next-gen autonomous vehicles in mixed traffic container terminals

Presenter: Berry Gerrits, Distribute Netherlands

Berry Gerrits holds a master’s degree in Industrial Engineering from the University ofTwente, The Netherlands, specializing in Operations Research. In 2016 he founded Distribute to bridge the gap between scientific research and practical applications, mainly by focusing on simulation projects. He is also a PhD candidate at the University of Twente, specializing in distributed systems and self-organization of fleets of autonomous vehicles in the logistics and transport sector.

Presentation summary: In collaboration with a large yard tractor manufacturer, distribute studied the impact of a decentralized control approach of autonomous yard tractors in a container terminal.

In this presentation Berry Gerrits showed how simulation assists us in quantifying the impact of autonomous yard tractors in container terminals and how allowing mixing in manual trucks impacts overall performance. He elaborated on the modeling approaches of the various components of a terminal, including traffic control in Plant Simulation and provided a live demonstration.