Collaborative Manufacturing: Critical for success in today’s complex Heavy Equipment industry

Heavy Equipment is getting smarter. Software- and electronics-driven equipment is increasing product complexity and the number of product configurations that manufacturers must deal with in today’s heavy equipment market.

Heavy equipment manufacturers today are being challenged by their customers, the competition, and government regulators, to develop smarter, more eco-friendly equipment in an increasingly difficult economic climate. As a result, heavy equipment is getting smarter. Manufacturers have a fundamental requirement to manage the rapidly increasing complexity of hardware, software, and electronics integration within heavy equipment to drive product development, product performance, and differentiation.

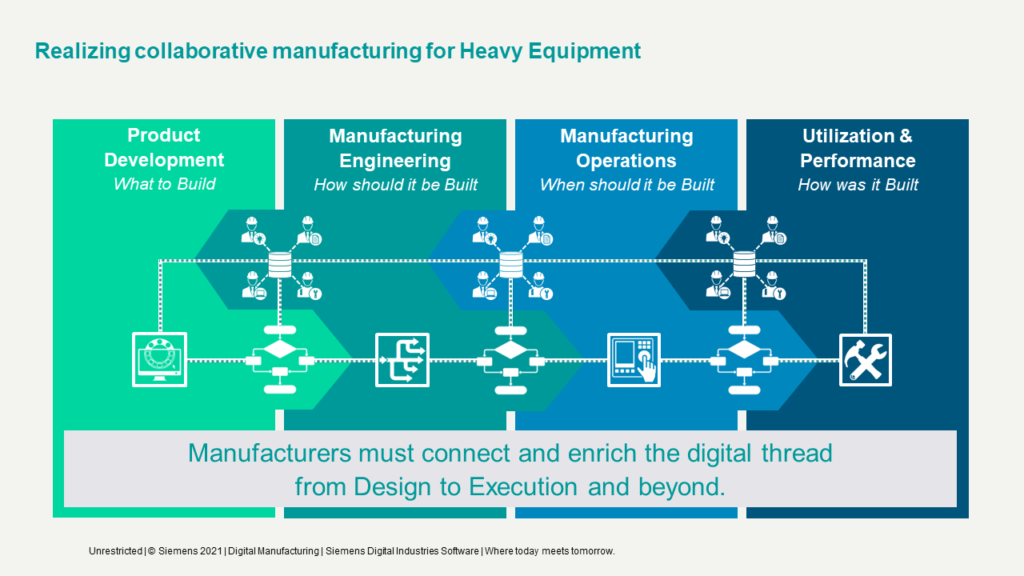

In a newly revised commentary, CIMdata states that heavy equipment makers need effective collaborative manufacturing capabilities that integrate their product development, production, and services processes and environments. Siemens is addressing this need with its Xcelerator portfolio. Its digital manufacturing capabilities are designed to help heavy equipment enterprises efficiently manage highly complex, configure-to-order product variations, enabling them to plan, produce, and service products as required to meet global, local, and specific customer requirements.

CIMdata believes that Siemens’ solutions for collaborative manufacturing can help heavy equipment companies build better, more effective, and more profitable businesses and improve their market competitiveness. Manufacturing enterprises facing today’s complexity challenges should include Siemens in their evaluation of solutions for collaborative, closed-loop manufacturing.

![Reshaping the world with digital manufacturing [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/07/Zvi_2024_2-395x222.png)