Automation World spotlights Siemens AI and cloud simulation powering a safer, more efficient manufacturing future

As industrial artificial intelligence (AI) advances, learn how Siemens Process Simulate X enhances manufacturing safety by leveraging AI and cloud technologies to create risk-free work environments where humans and robots collaborate more efficiently.

Automation World, a leading industry publication covering industrial automation technologies, recently featured Siemens in an article exploring how cloud and AI-powered simulation software are redefining manufacturing safety standards and improving efficiency. The discussion highlights how Siemens Process Simulate X software leverages AI and cloud-based simulation technologies to minimize safety risks, improve ergonomics, and reduce human error.

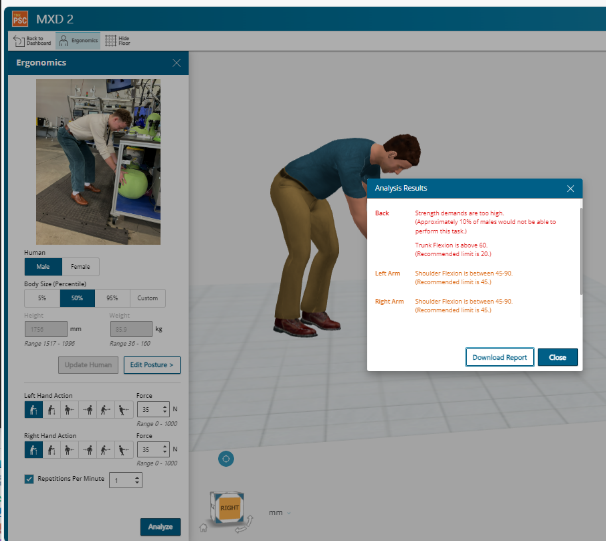

In the article, learn from Siemens experts and explore how AI continues to shape the future of industrial automation as manufacturers are increasingly adopting AI-driven solutions to enhance workplace safety and improve overall production. Siemens Process Simulate Collaborate Ergonomics feature exemplifies this shift, setting a new industry standard for integrating human factors and AI into automation strategies to improve safety and efficiency. The core innovation driving this is the integration of human posturing with Process Simulate Human technology combined with AI, which helps process a 2D image to generate a skeletal posture. Process Simulate Collaborate Ergonomics utilizes Process Simulate Human technology to convert the AI-generated skeleton into a 3D human model.

In the Automation World article, learn how manufacturers can accelerate safety enhancements by adopting cloud-based simulation software like Process Simulate X, providing a cost-effective, scalable, and secure solution to plan, simulate and validate robotics processes and human tasks.

The role of AI-driven ergonomics, virtual reality and cloud solutions in manufacturing safety

In the article, Siemens simulation expert Josh Carlson, Technical Product Manager for robotics and automation, emphasizes the critical role of automation strategies in enhancing workplace safety — while also improving production efficiency and product quality. A key focus is Siemens Process Simulate Collaborate Ergonomics, an AI-powered tool designed to optimize human performance and mitigate high-risk scenarios.

Carlson also shares how Siemens Process Simulate X Human Advanced includes virtual reality (VR) capabilities to combine accessibility with the immersive digital twin, resulting in enhanced design reviews, reduced physical validation, and ensured operator safety through real-time problem-solving in a 3D virtual environment.

The key to long-term success lies in selecting solutions that seamlessly integrate with existing workflows — including hardware safety devices like sensors, controllers, switches, and relays. AI-driven manufacturing simulation software, enhanced with cloud functionality and immersive technologies such as AR and VR, provides manufacturers with the best opportunity to reduce safety risks.

Josh Carlson, Technical Product Manager for Robotics and Automation, Siemens Digital Industries Software

Driving safety innovations: General Motors success story

Siemens works with manufacturers across an array of industries, but automotive and transportation, and aerospace and defense customers are leading the way with using Siemens advanced manufacturing simulation software. One standout example is General Motors (GM), who uses Siemens Process Simulate to help improve safety in manufacturing process design across globally distributed teams.

By implementing Process Simulate manufacturing simulation software and immersive technologies, GM has enhanced collaboration, virtually identified potential safety hazards earlier, and designed safer workstations. As a result, the automotive company has reduced both costs and safety risks, demonstrating the transformative impact of immersive technologies on modern manufacturing.

A safer, smarter future for manufacturing with simulation and automation

With the rise of cloud and AI-powered simulation technologies in Process Simulate X, manufacturers now have unlimited opportunities to use cloud technology to plan, simulate and validate robotics processes, human tasks and automation during the entire product development lifecycle from concept, engineering and commissioning to production and continuous improvement.

Explore how Siemens software is at the forefront of this shift, helping companies build safer, more resilient and efficient workplaces. As automation continues to evolve, embracing these advanced technologies will be key to minimizing risks, optimizing human performance, and shaping the future of manufacturing safety.