Automation World features Tecnomatix Process Simulate: the essential software for virtual commissioning [ARTICLE]

The adoption of a digital twin is rapidly becoming invaluable, particularly for testing and commissioning complex manufacturing processes. Explore the recent article published by Automation World, a key industry publication covering news and trends about industrial automation technologies, software and devices. Dive into the discussion between Automation World and Siemens about how manufacturers can leverage a digital twin and bring it to life with Siemens Tecnomatix Process Simulate software.

At a bird’s eye view, the comprehensive digital twin helps manufacturers to close the loop between the real and digital world to validate systems before the physical system is built, improving production quality and reducing downtime. However, the key piece that brings the entire puzzle together is how Siemens provides the technology from the Tecnomatix portfolio for manufacturers to create and leverage the comprehensive digital twin of their products, systems and production processes.

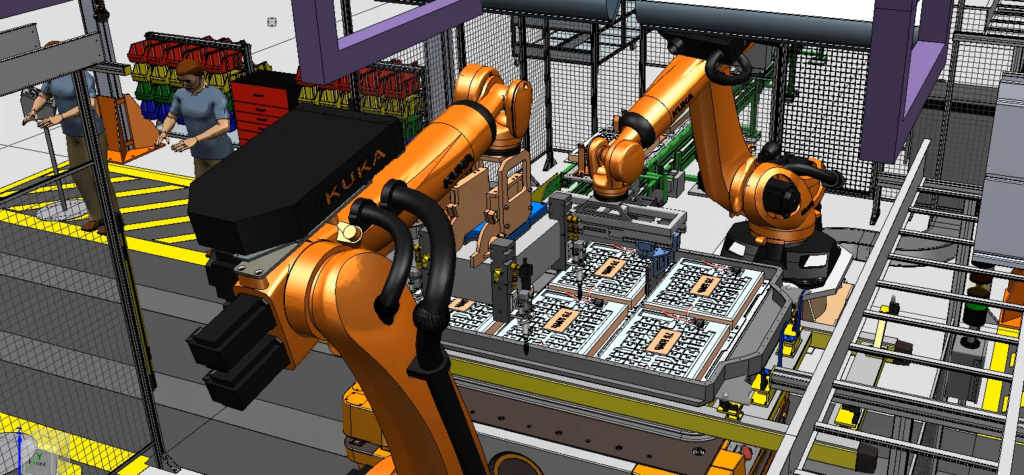

Explore the anatomy of a digital twin and how prominent industries, like automotive, electronics, battery and industrial machinery are rapidly increasing their robotics and automation capabilities and adopting the use of a digital twin with virtual commissioning to be more agile and competitive in today’s environment. In the article, learn how original equipment manufacturers (OEMs), integrators and line builders standardize on Siemens Tecnomatix Process Simulate for their digital twin of production because of the power and value it provides in areas of layout planning, cycle time validation, collision-free robotic motion planning and robotic offline programming.

Virtual commissioning: a critical component of realizing a comprehensive digital twin

The Automation World interview features Josh Carlson, Siemens technical product manager for robotics and automation, who emphasizes the importance of a digital twin and how it offers a comprehensive view of the entire lifecycle of a process or system, from design to operation, changes and commissioning.

A cornerstone of Siemens digital twin ecosystem is Tecnomatix Process Simulate, which powers manufacturers to simulate and optimize complex systems and equipment before physical implementation. Users can validate systems, plan layouts, ensure collision-free robotic motion, and perform offline programming. A prime example of the digital twin can be realized where a simulation or robotics engineer can test, validate and virtually commission a digital twin of a work cell, multiple machines/systems, or an entire production line.

Another example of a digital twin is an entire plant or distribution center. Siemens Tecnomatix Plant Simulation enables users to create a digital twin of their plant, warehouse, or distribution center and perform discrete event-based simulations. This enables engineers to test and optimize plant-wide layouts, resource and buffer utilization, energy consumption and throughput.

Industry applications

Carlson discusses with Automation World how the automotive industry is leading the way in reshaping manufacturing practices. Original equipment manufacturers (OEMs), integrators, and line builders are spearheading the adoption of leveraging the digital twin for virtual commissioning, with many standardizing on Siemens Tecnomatix Process Simulate. Notable customers such as BMW, Ingemat, Valiant TMS, and Wipro PARI are using Siemens digital twin technology to drive innovation and efficiency in their operations. Leveraging virtual commissioning software enables OEMs and integrators to test and validate how systems like robotics, automation, material handling, vision, safety and human operations integrate with one another.

The push for flexible manufacturing lines — multiple vehicles produced on a single line — and the increasing demand to repurpose existing equipment is making digital twin technology essential for the automotive industry. BMW, Ingemat, Valiant TMS and Wipro Pari are some of the customers using Siemens Tecnomatix digital twin technology.

Josh Carlson, Siemens Digital Industries Software technical product manager for robotics and automation

The tangible benefit of Process Simulate software

Manufacturers can leverage software in the loop (completely virtual) or hardware in the loop (a combination of virtual and physical hardware) during the virtual commissioning of the system. Shifting the testing and validation to the digital world is much less costly than catching problems on the floor during onsite commissioning and reduces overall commissioning time. Some other benefits from manufacturers that utilize virtual commissioning is increased confidence in the system they quoted meeting the customer requirements, competitive advantage in showing customers the system working virtually before they sign an agreement, as well as a key attraction for hiring and retaining top talent with modern technology.

From validating designs to optimizing processes and supply chains, the digital twin offers a multifaceted approach to enhancing productivity and reducing costs. By simulating production operations, analyzing sequences, and optimizing resource utilization, companies can achieve greater efficiency and agility in their operations. With Siemens Tecnomatix portfolio solutions at the forefront, manufacturers can harness the power of the digital twin to optimize processes, minimize risks, and drive innovation.

![Siemens simulation software powers Continental’s digital manufacturing journey [VIDEO]](https://blogs.sw.siemens.com/wp-content/uploads/sites/7/2024/02/continental-success-story-395x222.png)