Announcing Plant Simulation X: factory production planning powered by cloud technologies

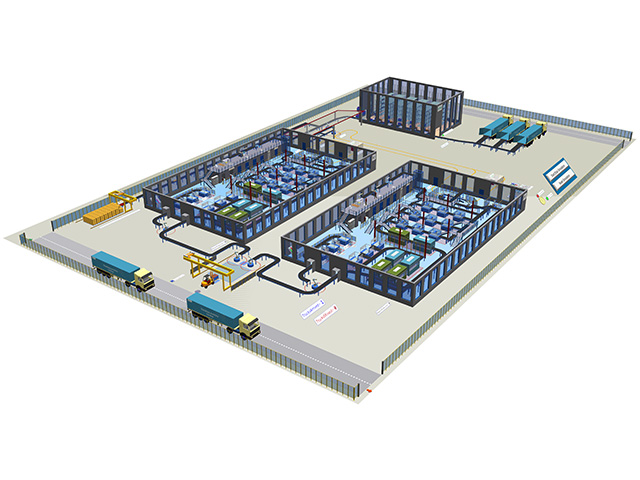

Introducing Plant Simulation X available in three, powerful, preconfigured packages with the flexibility, security, and scalability of cloud technologies. Create high-fidelity simulations of production systems and logistics processes using cloud technologies to analyze and optimize material flow and resource utilization.

Plant Simulation X is the next-generation solution for creating high-fidelity simulations of production systems and logistics processes. Harnessing the flexibility, security, and scalability of cloud technology, Plant Simulation X empowers you to analyze and optimize material flow and resource utilization from anywhere.

Choose from three robust, preconfigured packages, including: Plant Simulation X Essentials for fundamental modeling needs, Plant Simulation X Standard with enhanced capabilities for more complex simulations, and Plant Simulation X Advanced for the most demanding simulation projects. Elevate your experience with powerful add-ons, like Plant Simulation X Value Stream Mapping, to gain deeper insights into process efficiency. Cloud-based deployment ensures seamless software installation and configuration, driving productivity and enabling rapid expansion of digital manufacturing capabilities.

Next-generation factory planning & production software with the flexibility, security, & scalability of cloud technologies

Explore Plant Simulation X product offerings:

Plant Simulation X Essentials

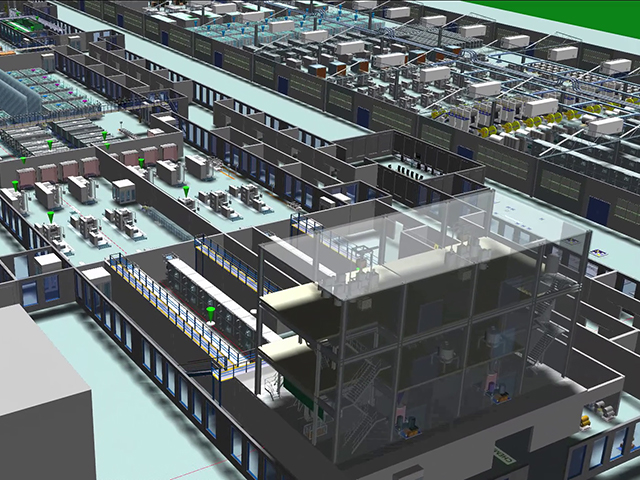

For manufacturers seeking a powerful entry point into factory planning, Plant Simulation X Essentials offers statistical simulation capabilities to production and logistics planning. With Essentials, you can create, analyze, and optimize 3D models of production systems using a core set of objects, libraries, and controls — perfect for projects with up to 500 objects. This package provides foundational tools for modeling and refining workflows to enhance efficiency and ensure optimal resource utilization.

Plant Simulation X Standard

Building on Essentials, Plant Simulation X Standard enables advanced statistical capabilities and supports larger-scale simulations with up to 4,000 objects. This package enables deeper analysis of complex production systems, allowing you to validate and optimize material flow, throughput, and overall system performance with a high level of precision to test and refine workflows before committing resources to production.

Plant Simulation X Advanced

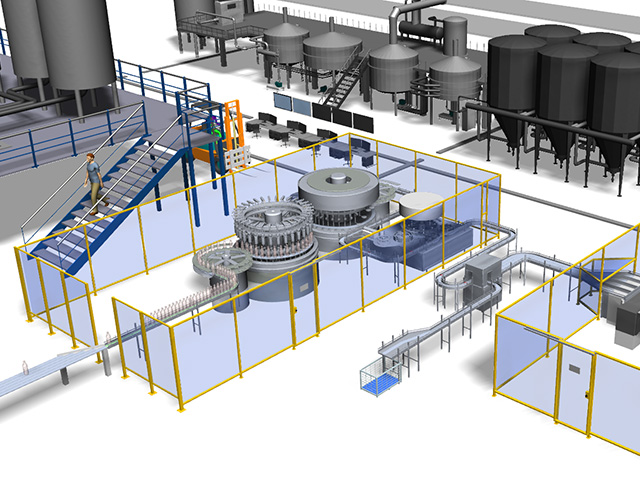

For those tackling complex robotic factory planning processes, Plant Simulation X Advanced provides unlimited model size and sophisticated tools for exploring every level of manufacturing planning and factory design. It incorporates comprehensive simulation capabilities to model and optimize material flow, throughput, resource utilization, energy consumption, and logistics to help inform decision-making across complex manufacturing and logistics environments.

Plant Simulation X Runtime

Plant Simulation X Runtime is a powerful solution designed to simulate, visualize, analyze, and optimize production systems and logistics processes based on models created with Plant Simulation X authoring tools. It allows users to execute simulations that validate and refine production and logistics, helping optimize material flow, resource utilization, and logistics across all levels — from global facilities to specific production lines. Runtime supports inputting real production data to enhance the accuracy and confidence in models, while enabling experiments with adjustable parameters to improve production throughput and overall performance.

Plant Simulation X add-ons to maximize your factory planning and production capabilities

Enhance your Plant Simulation X software experience with specialized add-ons designed to maximize your factory planning and production capabilities. These add-ons expand the core features of Plant Simulation X, allowing you to tailor the software to meet the unique demands of your projects and achieve more precise, actionable insights.

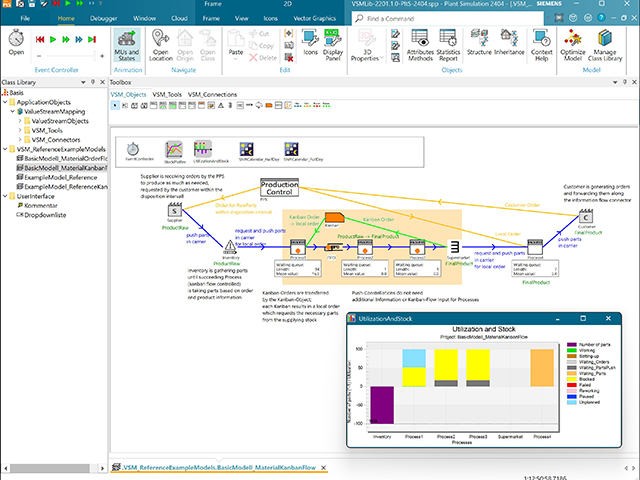

Boost your capabilities with the Value Stream Mapping (VSM) Library add-on, which enables you to customize Plant Simulation X for in-depth analysis and optimization of your production processes. This powerful library combines the strategic advantages of value stream mapping with the detailed analytical power of simulation, providing tools to model, simulate, analyze, and improve value streams within a manufacturing or production environment.

With an ongoing commitment to innovation, we continue to introduce new add-ons, broadening your modeling and simulation capabilities and supporting a more adaptable, efficient digital manufacturing workflow.

Plant Simulation X is a SaaS solution offering industry-leading capabilities to simulate, analyze, and optimize production and logistics at all planning levels. With 3D modeling, cloud-based flexibility, collaboration, and security, it delivers streamlined deployment for higher productivity and quick expansion of manufacturing capabilities. Tailored for varying complexity, Plant Simulation X offers cost-effective, customizable solutions to meet diverse digital manufacturing needs.