Visualization Mockup: Will it Fit?

Digital mockups are dealing with increased technical complexities and tight packaging requirements.

Fully configured products with an assumed amount of 10,000 components will consist of roughly 50 million unique part pairs (n squared/2) with possible clashes. Assuming a human can examine 1 part-pair per second, it would take more than 500 days to complete the analysis. This estimate makes it clear – validating a product will fit – requires a sophisticated, fast, reliable, and configurable clash analysis tool that allows users to focus only on relevant and important interference issues.

Teamcenter visualization mockup provides such extensive capabilities and helps customers to create high-quality products.

Teamcenter Visualization Mockup

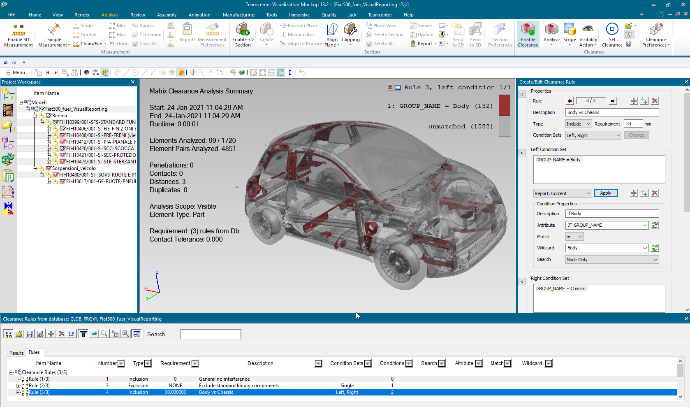

Within the visualization mockup tool, clearance analysis allows users to perform static or dynamic clearance analysis in a high performant manner. Detecting interference issues early is key to improve product quality and avoid potential design updates late in the product development process.

The clearance analysis capabilities in Teamcenter Visualization provide a rich set of tools and features to tailor the actual calculation to their specific needs. Users can:

- Adjust the calculation scope by viewing or selecting components or simply using the entire loaded product.

- Define clearance calculation granularity by defining whether to use leaf components, part components, or end items.

- Distinguish between contacts and penetrations by defining contact tolerance.

- Choose to use precise data if available; this will be more accurate but as well slower.

- Define a global clearance value.

- Define a variety of rules and conditions with specific clearance requirements.

- Define exclusion rules to exclude components from the clearance calculation.

After the actual clearance calculation, the results are displayed in the clearance results list. From there users can:

- Evaluate each identified part pair.

- Search, filter, or group results by various means.

- Walk through the results list by using keyboard arrow keys.

- Disposition each clearance incident and, as an example, assign them to a user or mark them as important.

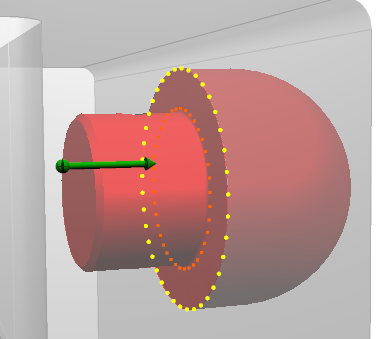

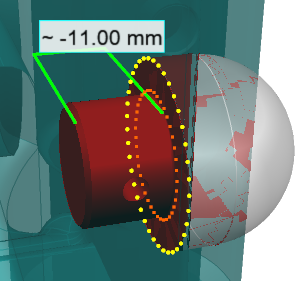

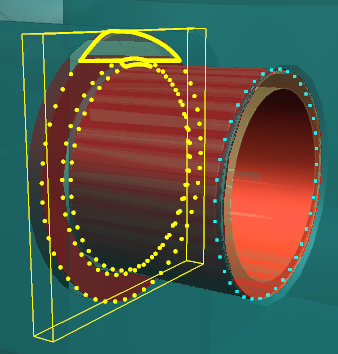

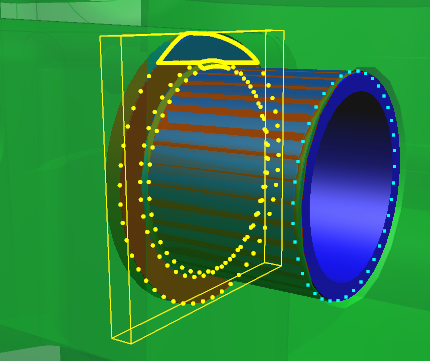

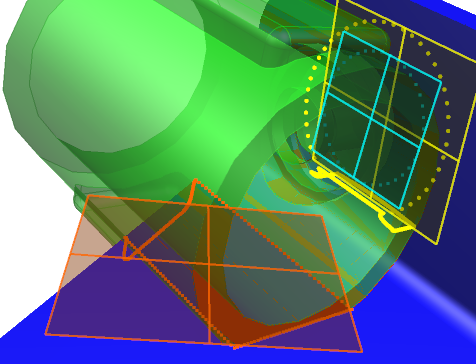

If you evaluate a part pair, it is important to identify the issue area fast. Hence, we can adjust the interference area in a lot of different and configurable ways. Examples are included below:

Shows interference volume, penetration vector, penetration/contact points

Automatically add sections (clipped or unclipped)

Shows measurement

Displays a bounding box around the interference area

Adjusts part display

Shows all penetration regions (if more than one exists)

The clearance capabilities found in Teamcenter Visualization Mockup will help find potential interference issues early in the product development cycle and improve overall product quality. If you’d like to learn more about how incorporating cloud PLM and desktop visualization software into a digital mockup addresses the challenges of the product design process, check out these links as well:

Visualization and Virtual Reality Blog Articles

Learn how real-time digital mockup design reviews can detect and resolve issues