New Teamcenter Product Cost Management Capabilities

Teamcenter product cost management 8.1 includes optimized features to significantly increase speed of cost estimation, accuracy and consistency. It supports the manufacturer in developing customer products and also helps the implementation of value-oriented cost management. With Teamcenter product cost management 8.1, cost engineers can now optimize their development costs incurred as part of the development of new product or they can enhance their existing products.

Teamcenter product cost management 8.1 provides the following enhanced capabilities:

-

- Integration Improvement: Using a product structure from Teamcenter within Product Cost Management, it is now possible to map additional attributes, such as to make or buy (procurement type), plant, technology, etc. Cost engineers can also create conversion rules that help them to map values consistently (e.g., to account for different nomenclature for a procurement type). More key features include importing plants, work centers, cost centers, activity types and tariffs in one single import which supports the detailed calculation. Users can outline a template and configure the tool list to be exported into the template to use the information in other applications.

-

- Configurable Look-Up Strategy and Quality of Price Look-Up: Cost Engineers can perform more flexible simulations with the configurable look-up strategy. The master data set (e.g., costs of a specific raw material) used for a calculation can have multiple different values depending on location, quantity, and time. If precise information is required during a look-up and this is not existing in the database, a “fallback“ is applied. With version 8.1, the fallback strategy can be configured. Cost engineers can specify the number of months going back from the calculation date that is still to be considered as a “full match“ as well as to know how long the system might go back to give a “fallback“ result. For any given calculation, a report can be displayed showing the quality of the result in terms of master data look-up criteria.

-

- Cost Factors: Skill levels or energy costs can now be individually generated, imported, exported, deleted and applied in the calculation. This allows cost engineers to adapt Teamcenter product cost management better to their individual costing structure and keep their individual naming conventions.

-

- Technology Classification and Material Calculator Templates: Cost engineers can now associate a manufacturing step by classification to a specific manufacturing technology. Corresponding technology properties and parts per cycle can be used to drive mass calculations in a simplified manner (e. g. by import). Material calculator templates allow customers to leverage their own classification scheme.

-

- Tool Costing – Purchase Part Price Flexibility: With version 8.1, cost engineers are able to generate, manage and use individual prices for purchased parts in the master data. They can also define individual prices of springs and thus improve the accuracy of the tool cost calculation.

-

- Full Text Search: The full text search capability is now extended so cost engineers can search for all objects including product and tool cost calculations. The improved visibility to search results that are displayed and sorted in a well-arranged grid view can help people save time.

-

- Quick Editor: Teamcenter’s newest Product Cost Management updates includes editable fields that provide cost engineers the flexibility to edit calculations with minimal effort.

-

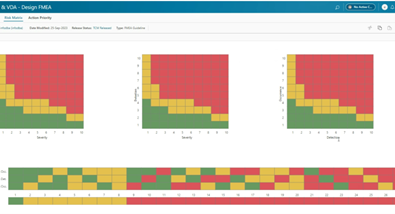

- Profitability Calculation Enhancement: Version 8.1 includes target key performance indicators (KPIs) for a project profitability calculation. They can be defined and the corresponding sales price required to achieve the KPI will be calculated. Overarching targets can be considered in an efficient way and sale price targets can be set accordingly. It is possible to calculate the residual value of equipment after the project ends. Consider corresponding cash-flows (especially cash-in at project end), it increases overall accuracy and supports the decision making process. Within version 8.1., cost engineers can calculate cash flows on a product level and display the KPIs. Improved identification of outliers offer the basis for decision making on possible corrective actions.

-

- Welding Cycle Time Calculator: A new cycle time calculator for welding technologies can calculate cycle times based on welding speeds that can be individually defined. A range of welding technologies is available in the product. In addition, a company’s own welding technologies or permutations with individual welding speeds can be defined.

-

- Korean Language: Teamcenter product cost management is now also available in Korean language to help serve our diverse customer base.

Cost engineers repeat constantly steps during their estimating process. With the new Teamcenter product cost management 8.1, companies can tremendously increase costing speed as well as accuracy and consistency. These improvements support cost engineers not only in controlling and minimizing the planned product costs during product development, but also in controlling the actual product costs as well as the continuous product costs process optimization throughout the product lifecycle.