Forward-thinking Failure Modes and Effects Analysis

Does your business need to implement a better Failure Modes and Effects Analysis (FMEA) methodology for deploying products?

Failure mode and effects analysis (FMEA) is a powerful tool to reduce design and process problems. The ability to assess the risks associated with potential product or process failures is essential.

Why use FMEA for effective collaboration and project implementation?

Collecting data in a comprehensive knowledge database, available to all relevant experts, is fundamental for success. A holistic FMEA approach can break down silos and create alignment across the enterprise for effective collaboration and project implementation. New projects can benefit from previous experiences. This reduces the development process cycle and the risk of defects at the beginning of the production cycle.

A fragmented approach to quality and production risk management can create manufacturing problems down the road. Quality teams determine how to manage all FMEA topics, yet they need to manage the related documentation during design, process definition and production. Moreover, a company needs to communicate a large amount of information for new product launches.

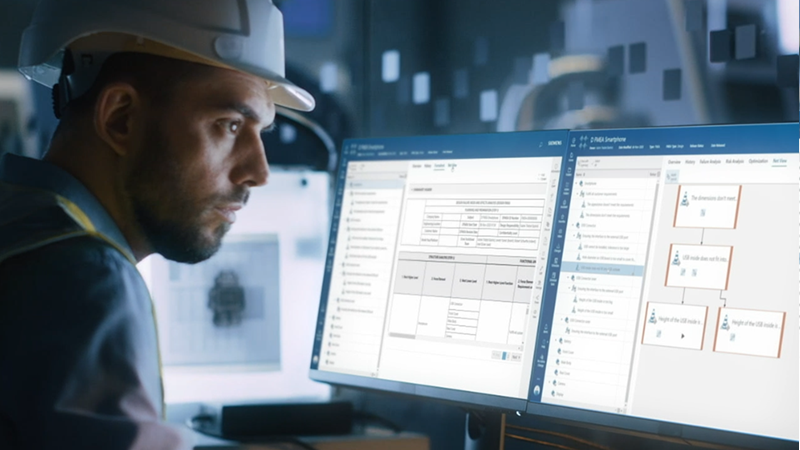

An efficient use of FMEA within a comprehensive quality solution, native on Teamcenter PLM collaboration platform, is the answer. Closed-loop quality (CLQ) enables manufacturers to avoid defects prior to production, improving functional safety and product reliability. A digital CLQ solution can cover the entire product lifecycle, creating a common repository of relevant data from all domains.

Risk analysis in manufacturing

Risk needs to be quantified and analyzed for all key processes and decisions. Risks in manufacturing can come from:

- The introduction of new equipment and major changes in the production process

- The introduction of new products, materials and technologies

- Changes in supplier outsourcing for a component alternative for cost reduction

A closed-loop quality management system can help ensure that FMEA-based risk assessments are carried out and managed efficiently. Large amounts of information must be analyzed and shared when new products are introduced. With a quality management system, all of the manual work and documentation goes into a common digital user experience. Quality personnel can then organize complex processes and designs and sort data at every level.

How can I strengthen risk management with the FMEA process?

Our expert Axel Eicker, Senior Product Manager – Teamcenter Quality FMEA, provides an overview about FMEA and related business processes to strengthen risk management. Leveraging on his expertise, Axel explains how manufacturers can support the FMEA process by following a stepwise approach:

- Why a company must consider quality management as an essential part of the manufacturing process.

- How to improve collaboration and reduce coordination efforts through aligned workflows for quality and engineering teams.

- How a native quality solution on a collaborative platform supports manufacturing companies in following the standard methodology in a unique environment.

You can discover more in our on demand webinar “Strengthen the FMEA methodology to achieve complete risk analysis”.

Axel gained his professional experience in the automotive industry and in the household appliance industry. He spent his entire career in quality management roles within the development departments of three different world companies. The moderation of FMEAs and the associated process and method optimizations were more or less the focus all along. Therefore, his goal is to develop the best FMEA solution as an integrated part of Teamcenter PLM and quality.

Discover how your enterprise can achieve risk assessment and quality planning processes using Siemens leading FMEA tool.

If you are interested in Quality Management topics, you might also check out these resources: