Solid Edge Startup Spotlight: The energy storage system of the future – Martin Schichtel from Kraftblock

Martin Schichtel, co-founder of Kraftblock, has a mission: develop a storage-based, sustainable energy system. With this, Kraftblock wants to establish the world’s leading energy storage solution and become an important part of the energy transition.

Kraftblock has been using Solid Edge from Siemens for the development of heat storage systems since 2018. The Saarbrücken-based company is particularly impressed by the functionality in the area of flow and heat simulation.

Read the full Kraftblock story, originally recorded for the podcast “Startup Hacks” by Bernhard Kalhammer, presented by Solid Edge.

Bernhard Kalhammer: Martin, why don’t you introduce yourself first.

Martin Schichtel: First, thanks for the invitation, it is great to be here. I am Martin Schichtel, a trained chemist, and as time went by, I got more and more involved in technology, but I’ve always remained true to research and development. This is how Kraftblock came about.

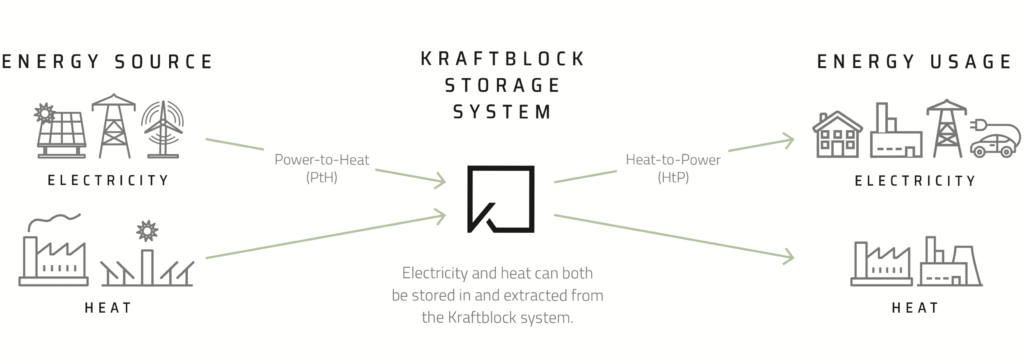

Kraftblock is an energy storage device or universal storage. Basically, it is a thermal storage unit, but it can also be used to transfer and temporarily store electricity and heat, as well as to use the stored heat and make it available again. All this may sound unspectacular, but it is a field of work that is incredibly interesting and fits perfectly into our times, where people talk about heat recycling, energy sources and renewables.

Bernhard Kalhammer: Super exciting! Tell us a little more about what we should imagine the product and/or the technology like. How does the Kraftblock work?

Martin Schichtel: The function itself is very simple. Imagine a large pot with gravel in it. I can now, for example, introduce warm air into this pot on one side, where the heat is then absorbed by the gravel and on the other side correspondingly cold air comes out. When I need heat again, I can simply reverse the process and pass cold air through the pot, which then heats up with the warm gravel and comes out as warm air on the other side. This is very simplified; it is technically a bit more complex. Since the performance of gravel is low, we have developed our own storage material, consisting of 85% recycled material, which cultivates sustainability from the ground up. This material enables us to offer the technical performance that is necessary today.

Bernhard Kalhammer: Exciting! On your website, kraftblock.com, one can also find good video material about it, which I highly recommend to the audience. It explains very clearly how Kraftblock works, and one can also see the pallets you mentioned in the video. These pallets are heated to a very high temperature and then put into a water pot. Could you explain what these pallets are made of?

Martin Schichtel: It is a special invention that took a total of eight years to develop. As I said, the components are 85% recycled material, such as slag from steel production or so-called furnace waste, which is created when old, large furnaces, including steel furnaces, are newly insulated. This actual storage material is then supplemented with a special binding agent that glues these individual components together. At the same time, it has other positive properties. For example, it increases the conductivity of the storage material, but also protects against aggressive influences that occur in different exhaust gases. It is technically complex and that is why it took so long to develop it.

Bernhard Kalhammer: How did the whole thing come about? How did it come to the development of these pallets on the one hand and Kraftblock on the other, was there a university background?

Martin Schichtel: There only was a university background in so far, that I used and still use the knowledge that I acquired during my doctorate. The idea came up in 2008, although at that time it was not yet about founding a company and building a startup. For me, it was more of a scientific challenge. At the time, I had seen a report on television about a concrete heat storage tank from Züblin DLR and found it exciting. Concrete is a cheap material that is available everywhere and from which you can make a lot of things, and I thought the simple operating principle was great.

What bothered me, however, was that the developers were talking about a “high-temperature storage unit” that can withstand 500 degrees. I must mention that I worked a long time in the field of ceramics and technical ceramics, where 500 degrees is a warming temperature and nothing below 1,000 degrees is considered a “high temperature”. I called the developers for a discussion and we spent a day together, developing a strength-weakness profile of the concrete. That is when the scientific challenge started for me: How can you replace, e.g. cement or sand, with a low-cost material that offers better performance. I did some experiments and tinkered with the classical approach of literature research, problem definition etc., until I found a material system that made sense to build as a heat accumulator.

Only then did the founding idea come up and the question of what I had to do, what the market looked like, who the potential customers might be and what their processes might be like. That started in 2011/2012 and I took my co-founder Susanne on board in 2012/2013. She is a real businesswoman, has the complementary know-how to mine, with a very good background in financing. Together we wrote the business plan and founded Kraftblock in early 2014.

Bernhard Kalhammer: But before that, during the idea and design phase, you were by yourself, is that right?

Martin Schichtel: Exactly, at first it was all about the material. I found it incredibly challenging to develop something lean, sustainable, and affordable that also performs well. For me, good performance meant that the temperature range had to be extremely broad and not end at 500 or 800 degrees, but rather be able to go much further. It also meant, that the material had to react quickly to loading and unloading processes. I cannot wait for an hour until the heat is inside the material. Instead, it must be done within a few seconds to minutes. I found this fascinating and that is why I got so involved.

Bernhard Kalhammer: In the last six to eight years there have been a lot of failures in product development, right? How did you deal with them and how did you motivate yourself to keep going and developing until a functional prototype was created?

Martin Schichtel: I think it is simply important that the vision is always in the back of your mind. If you have learned and worked in natural sciences, you are quite used to these failures. On the other hand, it was also something that I find somewhat contradictory in the human psyche: you learn by making mistakes, but nobody likes to make mistakes. And you must pick that up somehow. You simply must accept making mistakes, learn from them and above all draw the right conclusions from them. For me, the vision was always there, as well as the perspective. The intrinsic motivation to reach the goal was incredibly high.

Bernhard Kalhammer: I know this only too well from my discipline, growth hacking. Tell me, what was the biggest growth hack during the development of Kraftblock?

Martin Schichtel: I think the biggest hack was less in the development of the actual product, but more in business development. Namely, in a relatively unclear jungle as far as waste heat is concerned. You simply cannot find any reasonable figures or studies on this topic. The heating market is generally neglected in Germany, although it accounts for 52% of the total energy in Germany. It is only now beginning to break open. But to find the application that you can scale with one system and few adjustments in this thicket, that was the biggest hack so far.

On the development side, it was to get to the current combination of materials at some point, with which you can achieve the goal of producing a universal storage system. You can work with it between 0 and 1300 degrees, you can load it with hot exhaust gas, with mineral oil, with liquid salt, liquid metal or whatever. Being able to produce this on a universal scale is due to the material and when this development was finished, it was definitely our growth hack on the material side of things.

Bernhard Kalhammer: In other words, two hacks, so to speak, one in business development and one on the material side. You also use the Solid Edge software from Siemens. How do you use Solid Edge for the development of Kraftblock?

Martin Schichtel: On the one hand, Solid Edge is a tool for us to further develop the inventory system. We now have version 1.0 ready, i.e. the material for 1.0 is ready, the core memory for 1.0 is ready, but the whole thing is subject to further development. This core system is now transferred to Solid Edge, the CAD function, and we use flow-ifs to perform a wide variety of simulations on it. These are mainly thermal simulations and we use Solid Edge to integrate our approach into our customers’ system in terms of software. We can do a simulation and report back to the customer how high the overall efficiency is and what could be saved. They also see from the simulation that the whole thing has no impact on their production process, which is a particularly important thing, to “never change a running system”. Therefore, you must deliver almost 100% reliability, if you want to get to the system in question. Solid Edge supports us extremely well here.

Simcenter FLOEFD is a great simulation tool for us because we can run a complete simulation within an hour. For a classic load simulation in a process, Solid Edge is perfect and above all, incredibly fast. I have a complete simulation ready within an hour and can make small changes in the planning, if I notice that something is not quite up and running. Afterwards, I can immediately run the simulation again and do four or five iterations to get to the goal.

Bernhard Kalhammer: What was the best advice you got from another entrepreneur? Maybe you also have some advice for prospective founders?

Martin Schichtel: Move quickly, but also wait and see. It sounds like a contradiction, but I think everyone who has ever worked with a corporate knows, that the clocks tick differently. You must maintain your startup speed, but also wait and see until the necessary feedback comes from the other side, to move forward. If you let the two worlds collide without this awareness, then every project will go wrong at some point because of the different expectations.

Bernhard Kalhammer: Martin it was a great interview with you. What you have achieved with Kraftblock and what you will achieve in the future is fascinating and especially inspiring.

Thank you very much for your time Martin.

Martin Schichtel: Thank you very much, I had a lot of fun.

If you want to hear the complete episode in German, recorded on October 25th, 2020, visit https://startuphacks.de/startup-hacks-podcast-94-der-energiespeicher-der-zukunft-martin-schichtel-von-kraftblock/

To learn more about the Solid Edge Startup Program click here.

To apply for the Solid Edge Startup Program click here.