Resolving PCB Design Collaboration Issues

When designing printed circuit boards (PCB) during product development, coordination between mechanical and electrical engineers is critical. While this collaboration is important to the design of all electromechanical products, it’s especially challenging when adding PCBs into products with only recently added electrical content.

The ability or inability of teams to work seamlessly together impacts all stages of product development.

Communication and collaboration between domains is enhanced by working in an integrated 3D CAD environment.

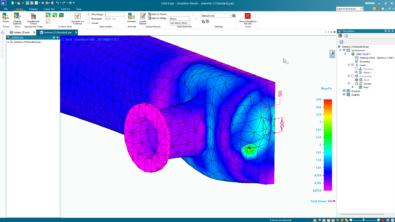

With an integrated 3D view of PCB layout, both mechanical and electrical engineers can immediately validate designs to identify over- and under-constrained areas, thereby freeing up real estate and reducing the number of potential electrical concerns.

Accelerate and improve PCB design development

Our latest white paper titled, “Enabling Fast PCB Development”, outlines how to effectively deal with ECAD-MCAD collaboration issues in PCB design and the benefits of using 3D technology in Solid Edge to enhance collaborative efforts between domains.

Effective ECAD-MCAD collaboration provides the following benefits:

- Increases productivity

- Improves design robustness

- Increases collaboration and efficiency

- Enables first-pass success

Being able to view and understand information in 3D puts you in a position to create better PCB layouts from the start, both electronically and mechanically. Solid Edge provides you with full control over design intent and seamless communication between engineering domains, resulting in high-quality designs.

PCB Design and Collaboration in Solid Edge

Solid Edge PCB Design provides schematic capture and PCB layout tools that provide sketch routing, hierarchical 2D/3D planning and placement, and ECAD-MCAD collaboration.

Fully integrated 3D layout with placement, constraints, design rule checking (DRC) and photo-realistic visualization minimizes MCAD iterations. Solid Edge PCB Design uses a complete set of 3D constraints with dynamic collision detection and batch verification to ensure error-free electromechanical design.

Comments