Increase speed and improve quality of part manufacturing simultaneously

Design has become more complex and is increasingly driven by customer and design needs, which means we need software that is capable of meeting those needs. Imagine your computer numerical control (CNC) could make parts faster and your cutting tools lasting longer without an additional cost. Adaptive Roughing toolpath technology does all three!

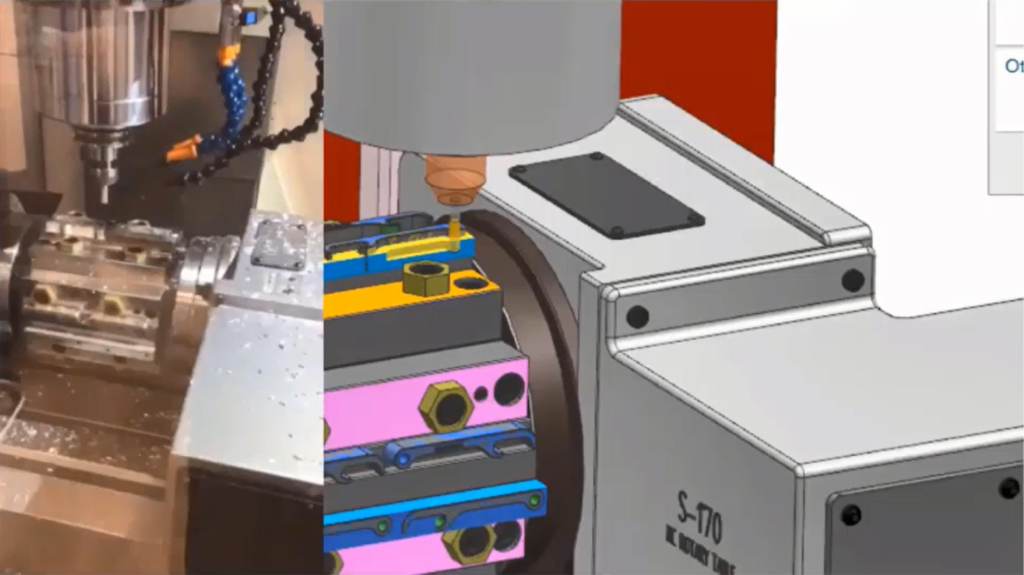

One of the best ways to always meet and exceed you customers expectations is to be aware of what is currently a trend and trying to adapt it to your workstyle. From cloud-based CA-x to Industry 4.0, today’s new technologies enable you to represent processes in a virtual world that matches exactly what’s going on in the real world. From this virtual environment, you can then use computer-aided manufacturing (CAM) software and techniques to validate and verify a process before going into actual production.

Learn about the latest industry trends in our latest on-demand webinar with Jim Wright, Senior Applications Engineer here at Siemens Digital Industries Software. In this webinar, we discuss everything from intelligent machining to the importance of digital twins in manufacturing.

Exclusive features for incredible tools

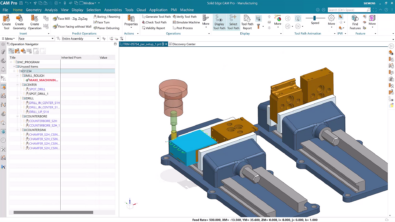

Solid Edge CAM solutions work directly on part, sheet metal and assembly models to help ensure accurate and efficient manufacturing processes. Manufacturing instructions created using Solid Edge can be easily updated to reflect any changes in the underlying design.

Ready to get started? Try Solid Edge CAM Pro →