From classroom to workshop: Blending education and digital craftsmanship

Estonian woodcraft company Artem Arbor designs and manufactures intricate laser-cut wooden toys and decorations with the help of Designcenter Solid Edge.

In Estonia, craftsmanship has always meant more than simply producing goods. Forests, traditions, and a strong work ethic have shaped creative practices for generations. Artem Arbor, a small woodcraft company founded by two friends, is firmly rooted in that heritage. While the brand is known for laser-cut wooden toys and decorative objects, its story is less about scale and more about the joy and discipline of making.

At the heart of the company is Märt Tammisaar, who navigates life as both educator and craftsman. “I’m a teacher, and I also have a small hobby company,” he says, describing how Artem Arbor began as a passion project alongside his teaching career.

The name Artem Arbor is derived from Latin, meaning “art wood.” From the beginning, the company was never intended to be a fast-growing startup or a shortcut to financial success. Instead, it grew from curiosity, collaboration, and the freedom to experiment. “I teach what comes before engineering — simple tools, woodcraft, metal craft, and their machines — in the eighth and ninth grade,” Tammisaar explains. “For example, students design their own key chain, and I cut it out with the laser using plexiglass.”

That experimental mindset was shaped long before he entered the classroom. Prior to teaching, Tammisaar spent summers doing physically demanding industrial work, including welding in sewer construction, and gained early exposure to CAD through military service.

Those experiences instilled a deep respect for hands-on skills and practical design. “It really helps you when you design something,” he says. “You know how something works and how this piece comes together with that one.”

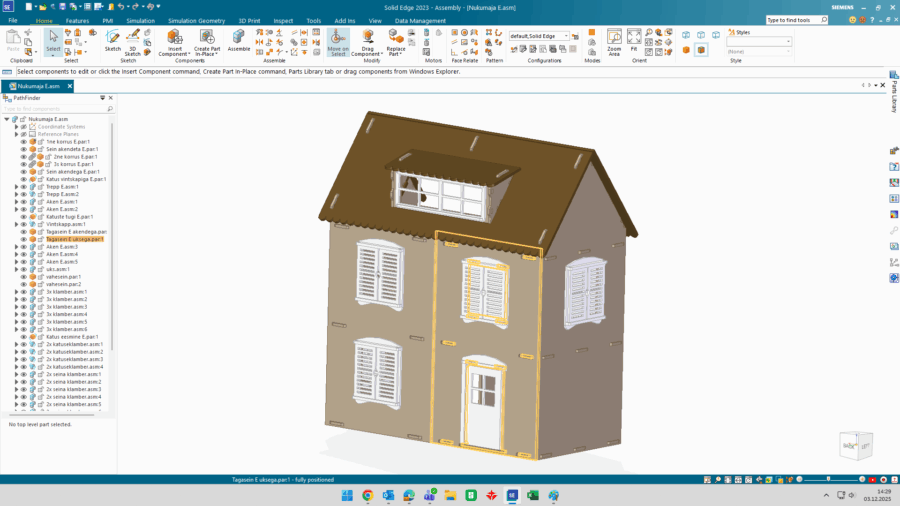

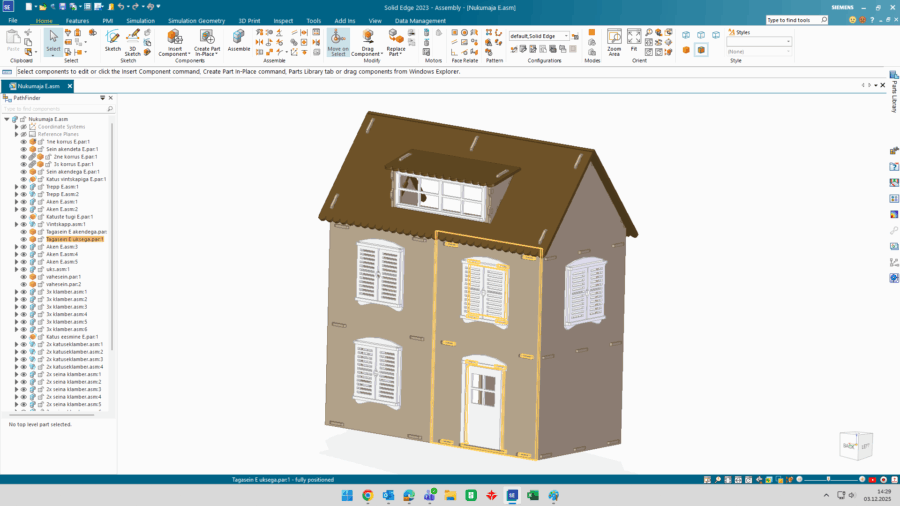

That combination of practical insight and thoughtful design is evident in Artem Arbor’s products. The company focuses on objects that are tactile, purposeful, and carefully considered. The designs reflect Estonia’s broader relationship with nature and making — where craft is not about nostalgia, but about continuity.

New iterations and new products

Even the smallest craft businesses must adapt and iterate. Over time, Artem Arbor has refined many products, sometimes with unexpected outcomes. One of its best-selling items — a miniature stable — started as a side idea rather than a core concept.

“That was just a random thought. Someone liked stables, and they were popular,” Tammisaar says. “So, we did a stable, and now it’s our most popular product, but not the one that we started with.”

It’s a familiar lesson for many makers: success often comes from emotional connection rather than technical cleverness alone. “You may think one way, but the customer is the other,” he adds.

Artem Arbor has never aimed for rapid growth or mass production. Estonia’s domestic market is small, so the company naturally looks beyond national borders, but success is measured on its own terms. “You want a self-sustaining company… to be able to do what you want to do,” Tammisaar explains.

For him, sustainability means having time — time to create, refine, collaborate, and solve problems. It also means maintaining machines and keeping the workshop running. As he jokes, “I’m the one who makes the machines go. If there’s maintenance and something’s wrong, then I’m the guy.”

His business partner, Erik Pappel, focuses more on day-to-day production and ideation. Together, they’ve built a small-scale micro-factory for wooden toys and decorative objects. Their partnership is less about rigid roles and more about trust and complementary skills.

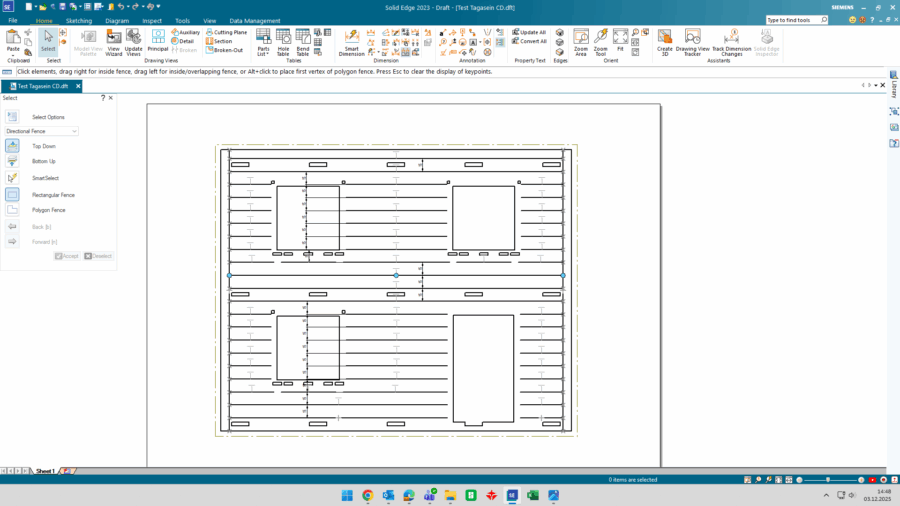

Designing with digital precision

While Artem Arbor is grounded in traditional craftsmanship, digital tools play a crucial role behind the scenes. Like many small businesses that blend art and engineering, the team relies on DesignCenter Solid Edge from Siemens to visualize and refine ideas long before materials meet machines.

The modeling environment allows them to iterate on geometry, tolerances, and joinery digitally, then move seamlessly into production using a CNC laser cutter. For a small operation, that precision shortens the distance between imagination and execution.

The value here isn’t automation for its own sake or producing millions of parts. It’s about control. Designcenter Solid Edge’s combination of synchronous technology and history-based modeling enables Artem Arbor to design like makers rather than machine operators. The result is products that retain a handmade character while benefiting from engineering-grade accuracy.

That same philosophy extends to how Artem Arbor engages with its customers. Each product feels personal because it is — shaped by real feedback, produced in small batches, and designed with longevity in mind. This isn’t factory manufacturing. It’s careful, intentional making.

Educating leads to good business

Tammisaar teaches, designs, builds, repairs, experiments, and adapts. His work demonstrates that craftsmanship can evolve without losing its foundation, and that independence is as much a mindset as it is a financial goal.

What makes Artem Arbor distinctive is its authenticity. It isn’t trying to be louder or flashier than it needs to be. It is simply a small workshop creating meaningful objects, guided by lived experience in both digital design and physical making.

“At the last Estonian teachers’ conference, the shop teachers visited my school,” Tammisaar recalls. “I ran a small workshop showing what we can do with CAD and lasers. I brought together everything I use — TinkerCAD for younger students and Solid Edge for older ones — in one room. There was 3D-printed work, laser-cut projects, and CNC-milled pieces. Their jaws dropped. They hadn’t seen that much machine-made work in a school workshop before.”

As he continues to grow both his business and his teaching practice, Tammisaar seems to have found a balance between digital tools and hands-on craftsmanship. By using the same technologies to educate students and build a company, he brings a practical, grounded perspective to both worlds.

Visit Siemens to learn more about the Solid Edge for Startups program and the Solid Edge Maker Community Edition.