Driving digital transformation in robotics engineering

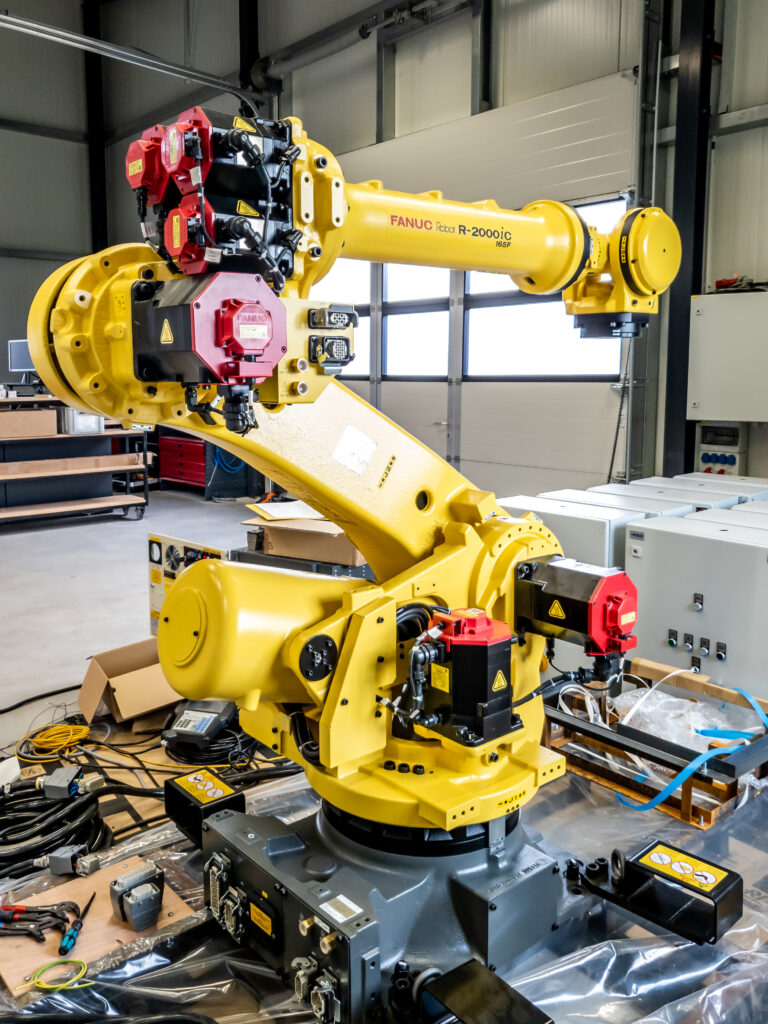

It’s no secret: robots are a core part of the future of manufacturing. In the industrial, commercial and consumer sectors, demand for robotic devices and systems is growing around the globe, moving from steady to rapid growth. More than 2.4 million industrial robots currently operate in global factories, especially in China, Japan, the United States, South Korea and Germany. Industrial robots are used extensively in the automotive, aerospace and electronics industries.

One area that is influencing this growth is an emphasis on global health concerns. Robots can be used to replace workers performing risky, arduous tasks, and are increasingly used for moving items in labs, hospitals and warehouses and for cleaning and disinfecting these facilities. However, this is just one example.

Dealing with increasing complexity and demand

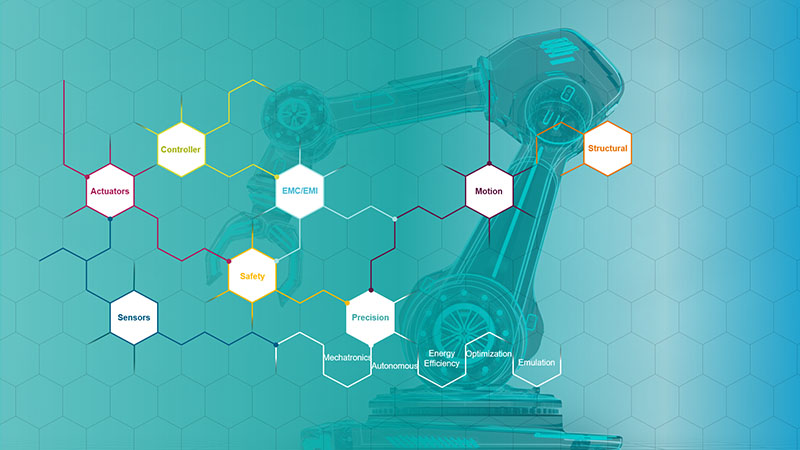

Not only is the number of robots increasing at an exponential pace, robots are also increasingly complex devices. Manufacturers of robotic devices and systems are facing significant challenges when it comes to balancing performance, including an increasing demand for flexible, intelligent automation, higher device complexity with more electronics and sensors, and an increasing focus on device performance, reliability, safety, and energy efficiency.

eBook

Industry Insights: Speeding product development for robotic devices

Manufacturers are responding to increasing demand for robotic devices and systems by digitalizing their product design and development processes.

An example of this can be seen in emerging robotic architecture. Common robotic characteristics include electromechanical assemblies, sensors and control systems. Smaller control devices that regulate sensors and provide basic control information are now often placed inside the robot instead of being routed to a large, remote controller. This may require more radio frequency (RF) communication devices and right-sized, optimized drives and local controllers to also be located in the robot.

The increasing complexity of products in terms of their electromechanical content can slow down the product development process and result in delayed time-to-market, lost revenue, project budget overruns and poor product quality. This makes advancing the robotics engineering field critical to increasing the adoption of robots across the board. By implementing software tools specifically developed to enable electrical and mechanical engineers to work together, both disciplines can actively collaborate during the design process. Using software tools that exchange data between disciplines make it easy to see and react to changes as the design progresses.

Finally, we’re seeing an increasing focus on performance and reliability. End users demand that robots support fast cycle times, be low maintenance, and have high safety standards. Manufacturers may address these concerns by implementing a comprehensive digital twin strategy with their product development process. A digital twin, a detailed 3D digital model of a proposed robot, adds data to a design as it progresses, then leverages this data to achieve product improvements such as optimizing the performance of both individual components and complete systems.

Embracing digital transformation

Investing in a digital transformation across all areas of product development can have a big impact on product development processes, especially in improving collaboration between engineering and manufacturing, responding faster to customer demands and bringing new products to market faster. Relying solely on prototype testing is time-consuming and cost-prohibitive. For this reason, robotics industry leaders are embracing the implementation of simulation and testing software to handle robotics performance engineering challenges. Simulation and testing software solutions like Solid Edge® provide capabilities that can help to engineer futuristic robots more efficiently.

On-Demand Webinar

Robotics engineering: Developing robots and robotic systems

Explore robotics engineering best practices using a cross-domain engineering software solution.

Solid Edge has helped small and medium-sized manufacturing firms like Ross Robotics, Skybridge, PATI and Brunner Elektronik to rapidly digitalize their product development processes across key areas, such as visualizing new robot designs for sales and marketing, managing customer and regulatory requirements, speeding up 3D mechanical design, designing electrical circuits and wire harnesses, integrating electrical components into mechanical designs, optimizing kinematic and dynamic performance, designing robot motion paths, and much more.

If you’re interested in exploring the full spectrum of what Solid Edge has to offer for the robotics industry, register to watch our on-demand webinar highlighting best practices for using a cross-domain engineering software tool for robotics engineering. During the webinar, you’ll learn how to evaluate the sizing of a robotic actuator to real payload and validate control logics with PLCs in SiL/HiL, how to validating the work envelope and performance of robot manipulators in real-world working environments, how to use simulation, testing and IoT to perform asset health monitoring, and how to achieve stricter targets for performance, reliability, safety and efficiency.

Join the conversation

Already a Solid Edge user? Connect with other Solid Edge users around the world through our online community.

To learn more about Solid Edge, visit solidedge.com.

Comments