Designing complex digital printing machinery using Solid Edge

LSINC Corporation has over a decade of experience in designing and manufacturing cutting edge digital-printing machinery. Their engineering team of 10 has decades of experience and has chosen to use Solid Edge to design proprietary components and to model complete machinery assemblies in 3D. LSINC manufactures their machines onsite with the aid of five CNC machine tools and extensive assembly and testing facilities.

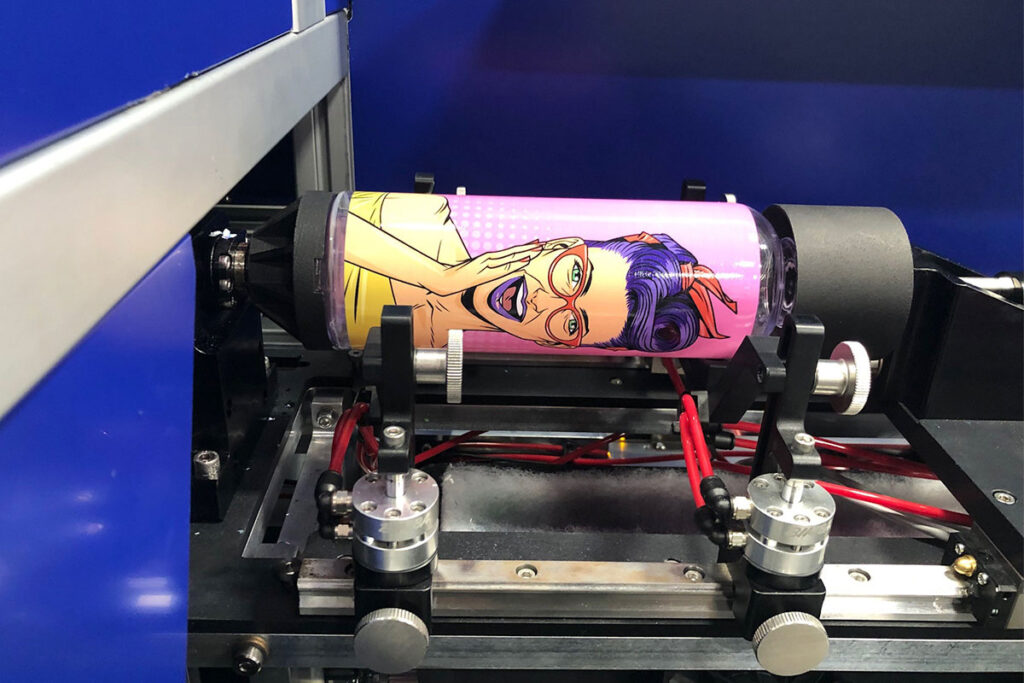

Printing high-quality images on 3D objects

LSINC’s ultraviolet inkjet printers produce high-resolution, full color images on 3D objects like baseball bats, drinking flasks, and wine bottles. You can see some examples in their online catalog. I found that to really appreciate the quality of the printing, and the endless creative possibilities, it is best to handle production samples.

An integral part of LSINC’s machinery are multi-axis positioning mechanisms that control multiple printer heads. These heads maintain an offset of around 1mm to the printing surface as the objects are rotated to ensure 360-degree print coverage. This proprietary technology enables amazing results for printing high-quality graphics on limited run promotional objects and packaging. This printing technology is an environmentally friendly alternative to using traditional paper labels and adhesives, and an automated way to replace manually intensive water transfer printing processes.

On a recent visit to LSINC’s facilities in Huntsville, AL, USA, I spoke with James Bullington, LSINC’s chief technology officer. James has a comprehensive background in product design and design consultancy and has been using Solid Edge to complete design projects since 1996 (Solid Edge version 2). Another example can be found in this article on the design of DNA testing cassettes for biotech company iCubate.

Complete assembly design for digital printing machinery using Solid Edge

James explained, “We model the complete assembly in Solid Edge including frames, mechanisms, and the key electrical components including connectors and printed circuit boards. For catalog components, we typically request STEP models from the supplier and integrate these into our assembly models. Having a complete model of the machine in a virtual environment enables us to check for possible interferences between moving components and perform stress analysis on load-bearing components. This helps ensure the performance and reliability of our equipment. We also take a modular approach to machinery design, reusing proven modules where possible to increase our efficiency and reduce costs.”

Reverse engineering to capture geometry of diverse objects

James continued, “In addition to modeling the complete machine in Solid Edge, we also model the objects that will be printed. Here we use reverse engineering, firstly 3D scanning the object to capture its geometry, and then using this scanned data to produce a 3D model of the object in Solid Edge. We can create smooth surfaces in Solid Edge to eliminate the imperfections we see in objects like glass bottles that have variability due to their manufacturing process. The printer heads can then follow a smoother trajectory while maintaining the optimum offset from the object, improving the print quality.”

LSINC’s chooses Solid Edge for their CAD tool, not just for the design of their digital printers but also for the diverse range of consultancy projects they undertake. James says, “From a design consulting viewpoint, Solid Edge offers a wide array of tools for manipulating non-native CAD geometry. When you’re bringing in client models and you need to modify them, Solid Edge has been very efficient for doing so. We also find that Solid Edge is a very straightforward and powerful tool for creating the complex surfaces that several of our design projects require.”

Comments