Frontloading flow analysis improves product performance

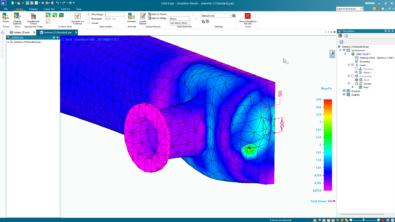

Optimizing cooling of electronic components using FloEFD for Solid Edge

Optimizing cooling of electronic components using FloEFD for Solid Edge

Do any of your products have fluid flow or heat transfer issues? Examples could include understanding the pressure drop through a valve, improving the mixing process for hot and cold water in a faucet, or keeping a power supply and its housing at a safe temperature. The Solid Edge Portfolio has an excellent solution for these design challenges: FloEFD for Solid Edge.

As you probably know Siemens acquired Mentor Graphics this year and we are in the process of making its electrical, electronic and mechanical analysis solutions more easily available for our Solid Edge users. FloEFD is the forerunner here, several Solid Edge customers have been using the standalone FloEFD solution for a number of years, but we took a major step forward in this area by adding FloEFD as an embedded solution within Solid Edge ST9 in 2016. FloEFD supports a wide range of fluid flow and heat transfer analysis types including pressure loss, flow fields, heat transfer, force prediction and mixing processes as shown in the graphic below. It also takes a unique “frontloading” approach to CFD (computational fluid dynamics) and makes this approach available as a tool that all product designers can use.

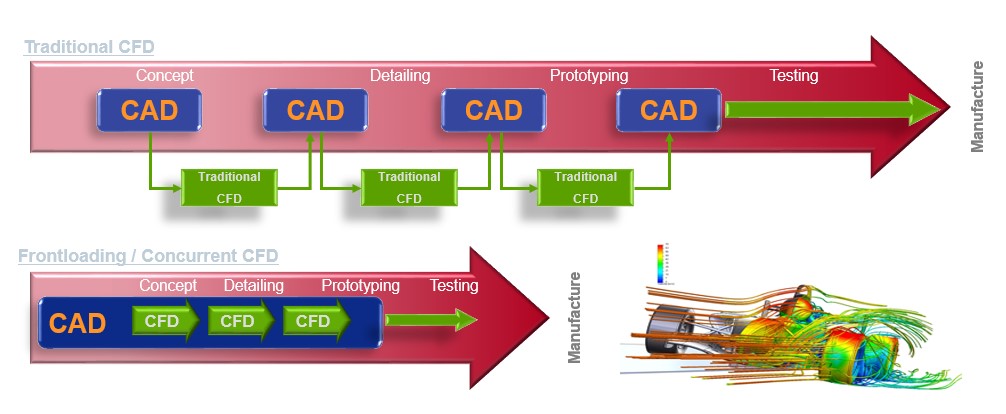

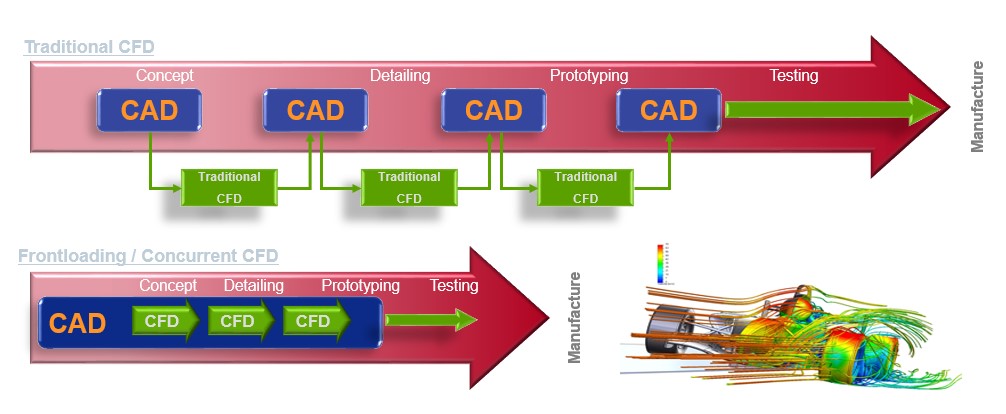

What is frontloading?

‘Frontloading’ refers to the practice of moving CFD analysis early into the design process where it helps designers examine trends and eliminate less desirable options, as well as reduce overall simulation and analysis time by as much as 75%. As the chart below shows, the cost of fixing problems in new products increases rapidly after the initial concept design phase. Also the potential for reducing overall product cost decreases quickly as the product development process moves into the detailed design, manufacturing and maintenance phases. Research shows that solving problems early in the design process results in lower product costs

Research shows that solving problems early in the design process results in lower product costs

This chart applies to addressing many different types of problems that can be encountered in the product development process, but I would argue it is particularly relevant for the area of fluid flow and heat transfer design and performance issues. For example moving a cooling fan to the optimum position in a housing early in the design process to address a hot-spot issue will minimize costs from late stage design changes, while also improving overall reliability and reducing warranty costs. FloEFD stores all the parameters for the flow analysis in Solid Edge and the analysis can be re-run easily as the fan is moved into different locations.

Frontloading enables CFD analysis to be run earlier in the product development process, with fast iterations

Frontloading enables CFD analysis to be run earlier in the product development process, with fast iterations

To find out more about the frontloading approach you can download a whitepaper from Mentor: “Top 7 Tips to Increase Engineering Productivity by Frontloading CFD”. You can also find many other resources specifically for FloEFD for Solid Edge.

And if you are interested in CFD in general, Mentor’s Engineering Edge journal has many in-depth articles on how designers in a wide variety of industries are solving their fluid flow and heat transfer challenges. I have a copy on my desk – it’s a bit like going back to engineering school!