What’s new in Simcenter Systems Simulation 2304

A new release to deal with tomorrow’s challenges

Simcenter Systems Simulation 2304 has just been released, containing many exciting new features that will help its users to go faster, deal with more complexity, better integrate and explore new possibilities. This blog is highlighting some of the new features in this release, which include Simcenter Amesim, Simcenter Flomaster, Simcenter Webapp server and Simcenter System Analyst.

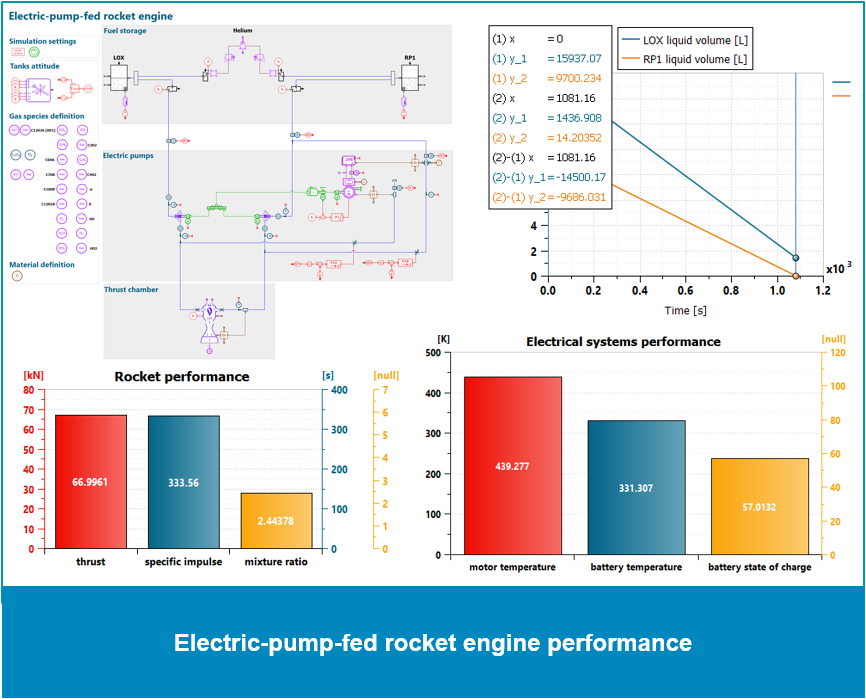

Use the new demos for a head-start

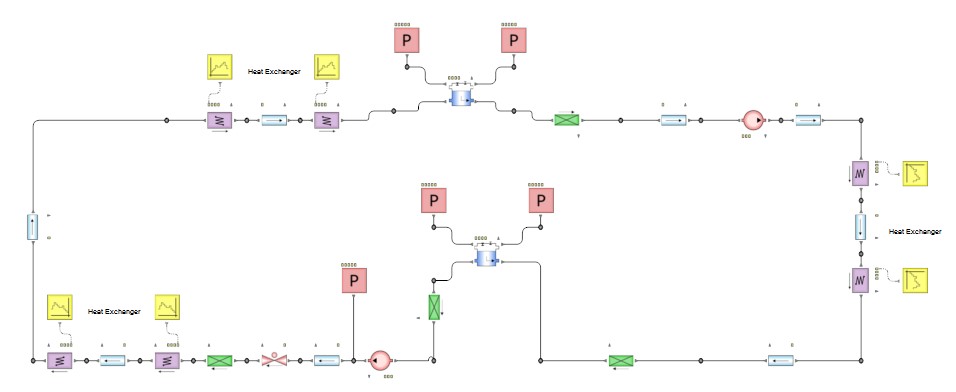

For aerospace engineers working on thermo-fluid space systems, Simcenter Amesim 2304 offers an all-new Space demo portal. It’s a unique entry point with an expanded set of templates for multiple Space systems. This will save you time on building models, so you’ll be able to run more tradeoff studies and better frontload integration decisions for various space systems.

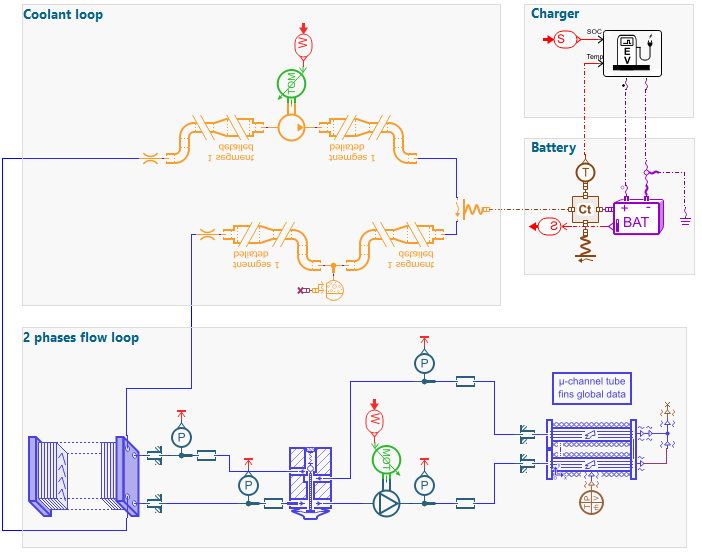

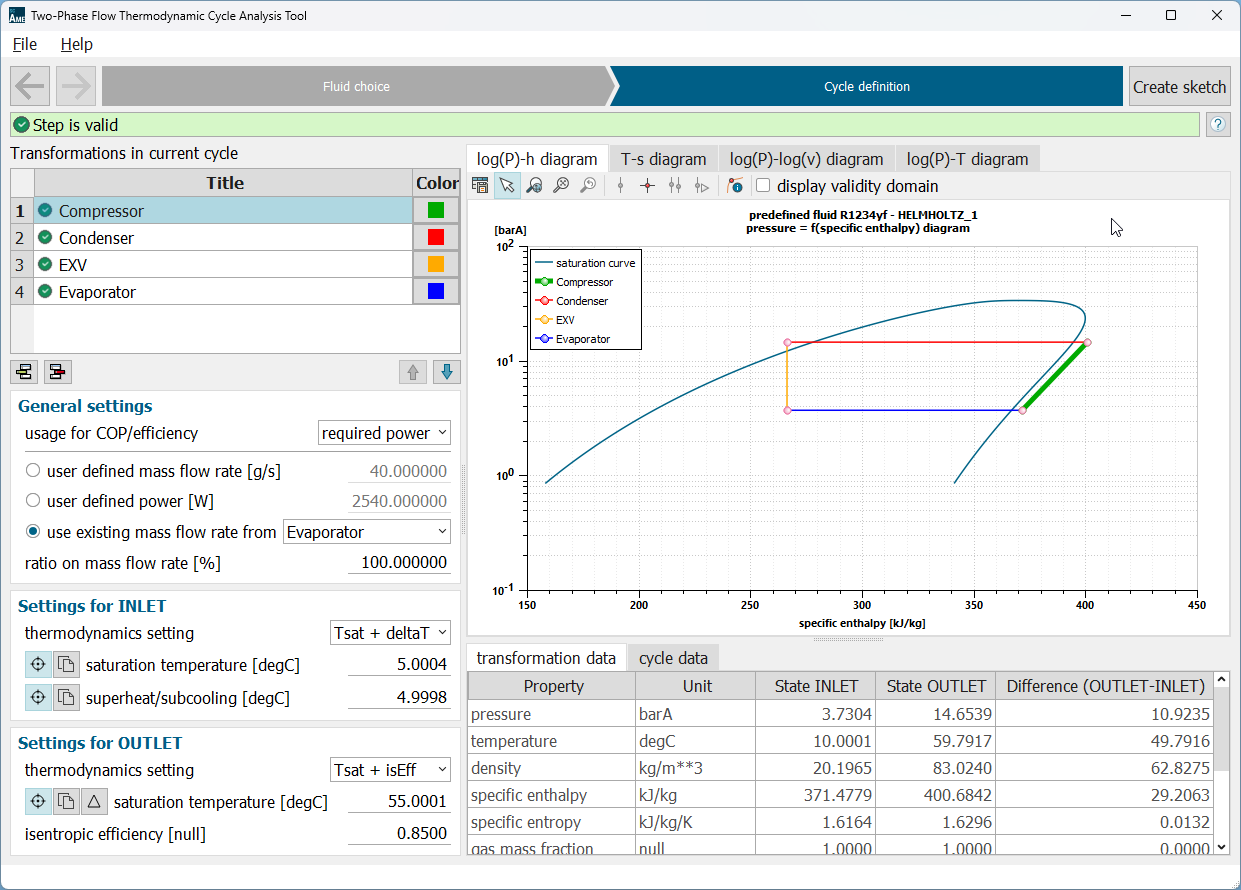

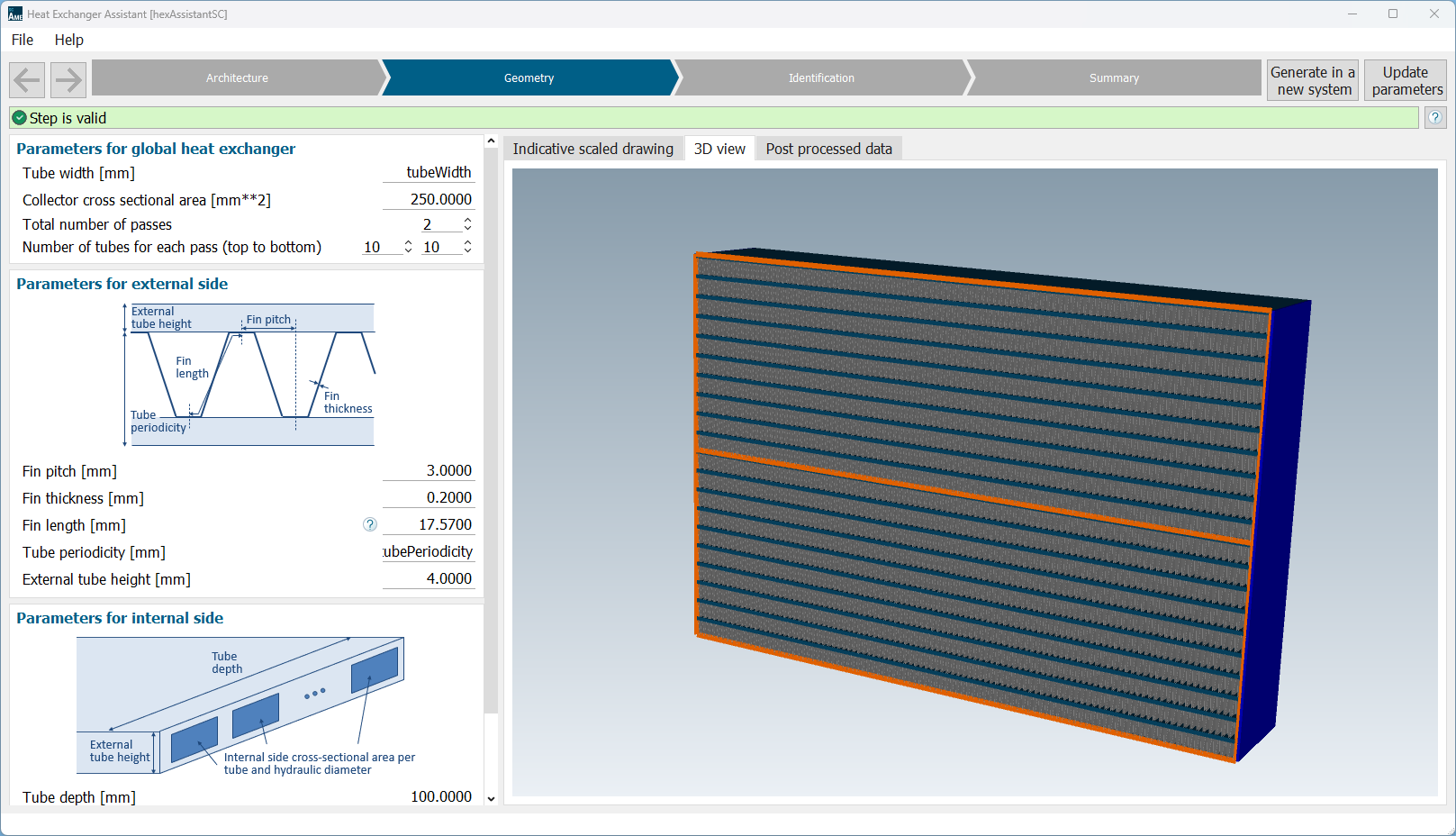

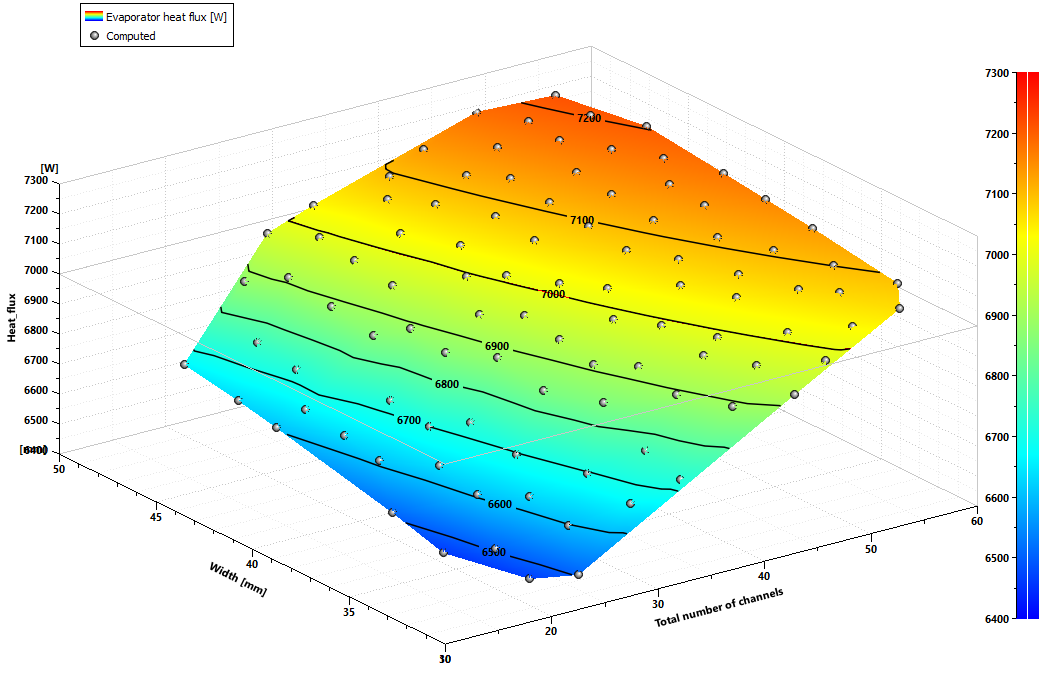

Next to that a complete workflow demo for battery thermal management has been developed, covering step-by-step descriptions and examples to support all stages of designing a thermal management system. Whether you’re sizing a heat exchanger, selecting the right compressor or defining the architecture of the entire thermal management system, you will find dedicated examples and how they can be integrated into an instrumented process from specification to final design.

Evaluate real-life scenarios easier and quicker

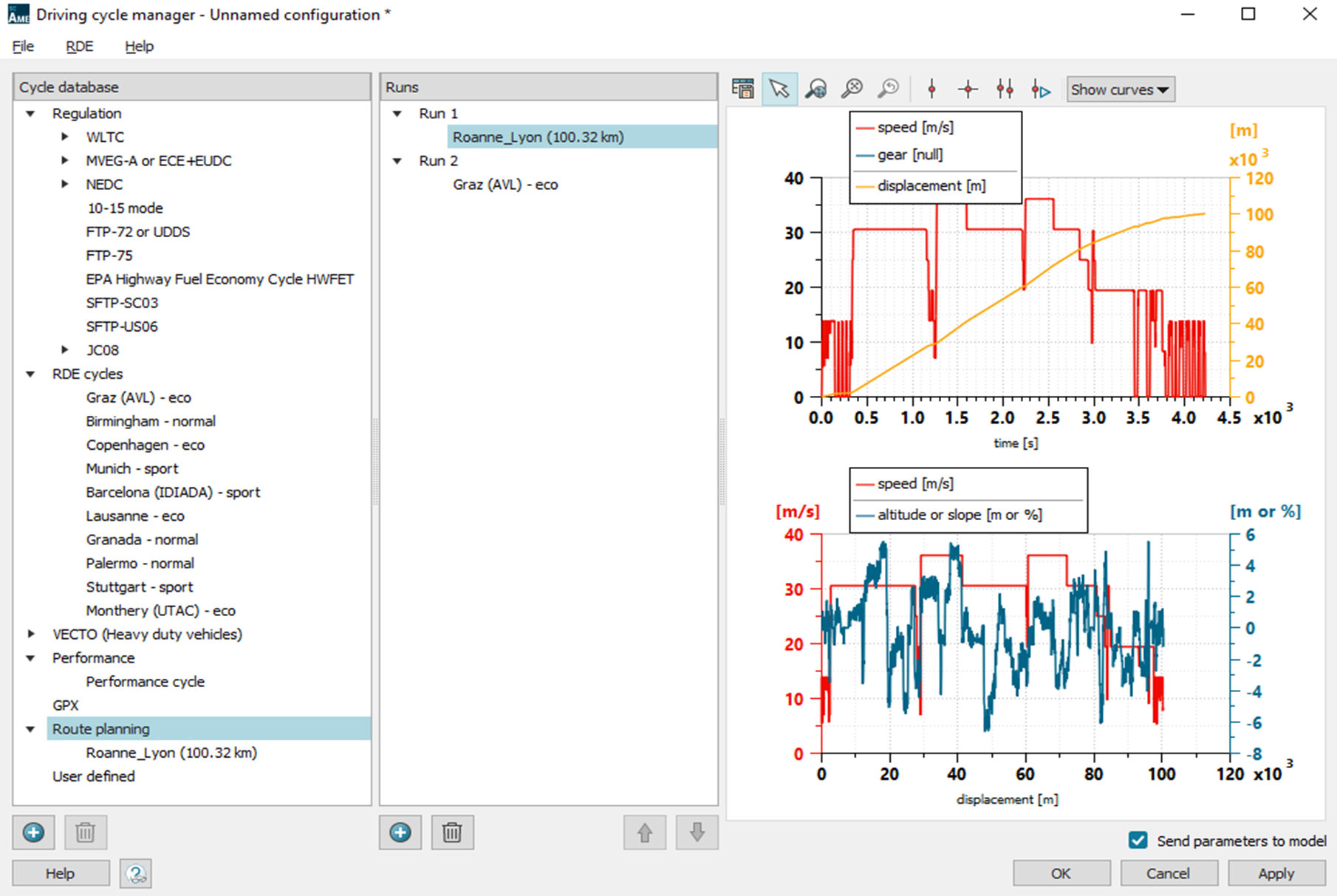

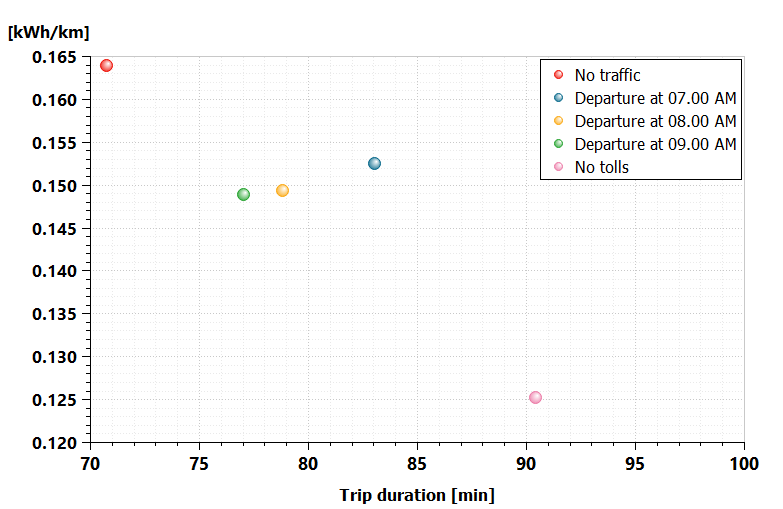

With the new features on routing and trajectory for both the marine and the ground-vehicle industry, Simcenter Amesim users can now add more realism to their simulations by including real-life scenarios.

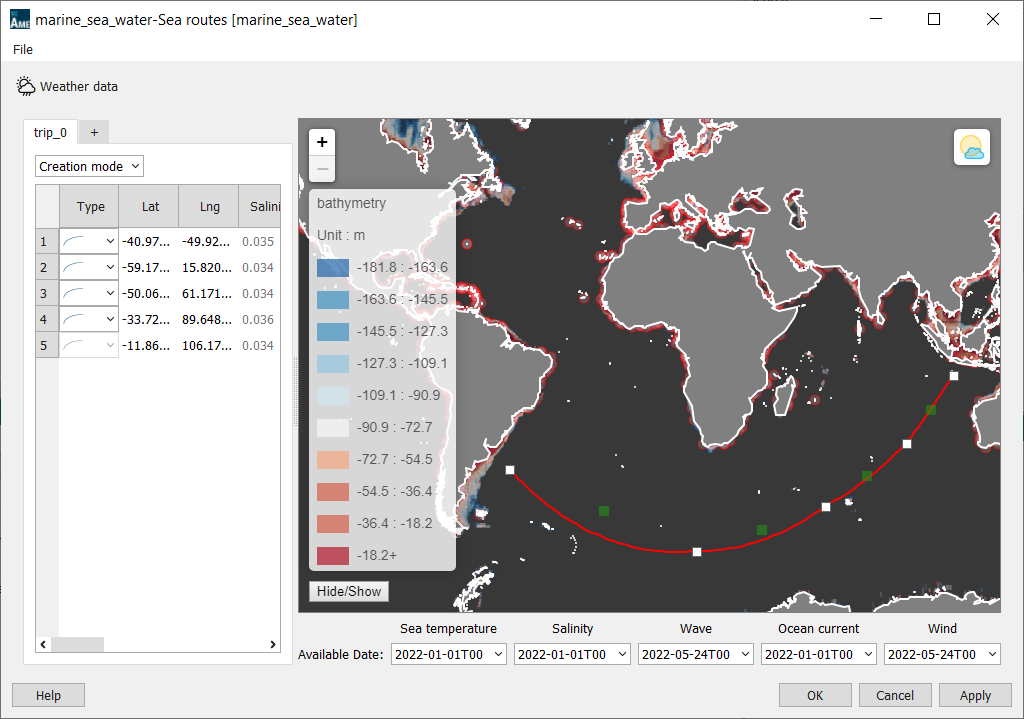

For marine (propulsion) engineers, it’s now possible to capture sea state change and its impact on ship propulsion performance with the new Sea Routes App. It offers a quick way to extract data like water salinity and temperature, but also wind, wave, and current data. This means that fuel consumption can be assessed with more accuracy since the ship resistance computation will be more precise.

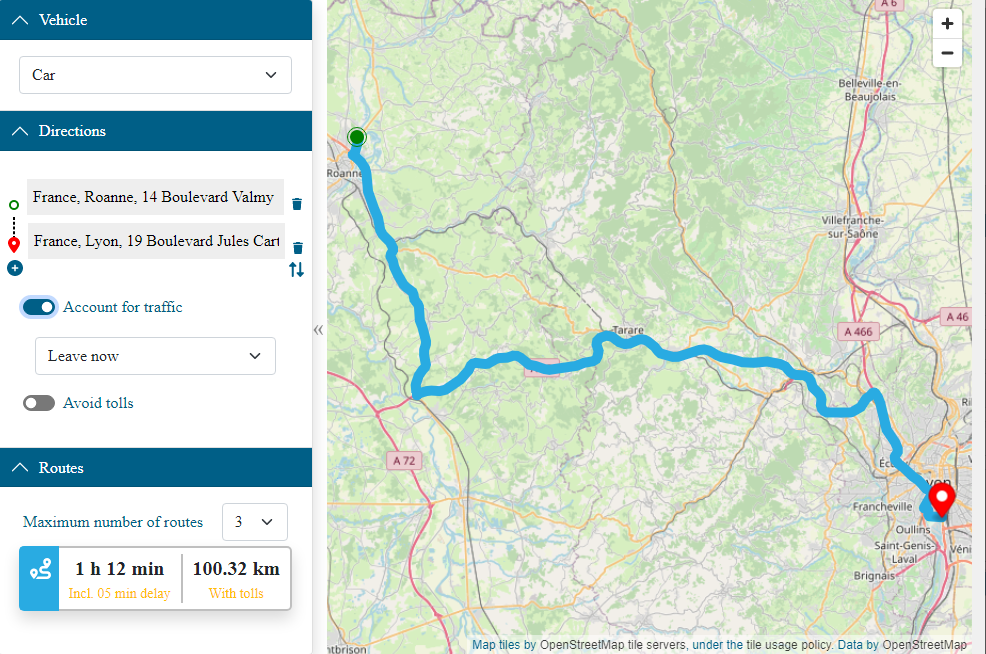

Engineers who work on any road vehicle and use GPX files to describe trajectories will benefit from the new Trajectory and Road Import Tool in Simcenter Amesim. With this tool you can quickly import tracks based on GPX files and filter them to generate a trajectory and road that will be followed by vehicle models.

Big steps for clean and sustainable mobility

For engineers working on new products for more clean and sustainable mobility involving batteries, hydrogen and electric motors, Simcenter Systems Simulation release 2304 offers many valuable new features to deal with the increasing complexity and to explore new possibilities faster and more efficiently.

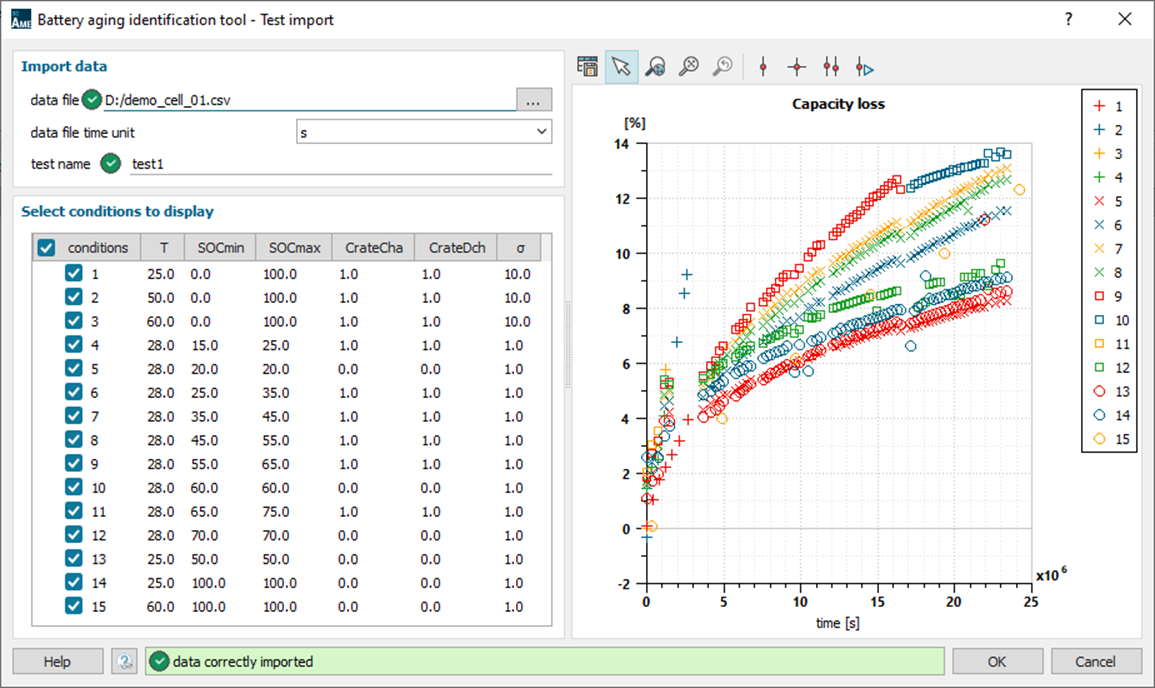

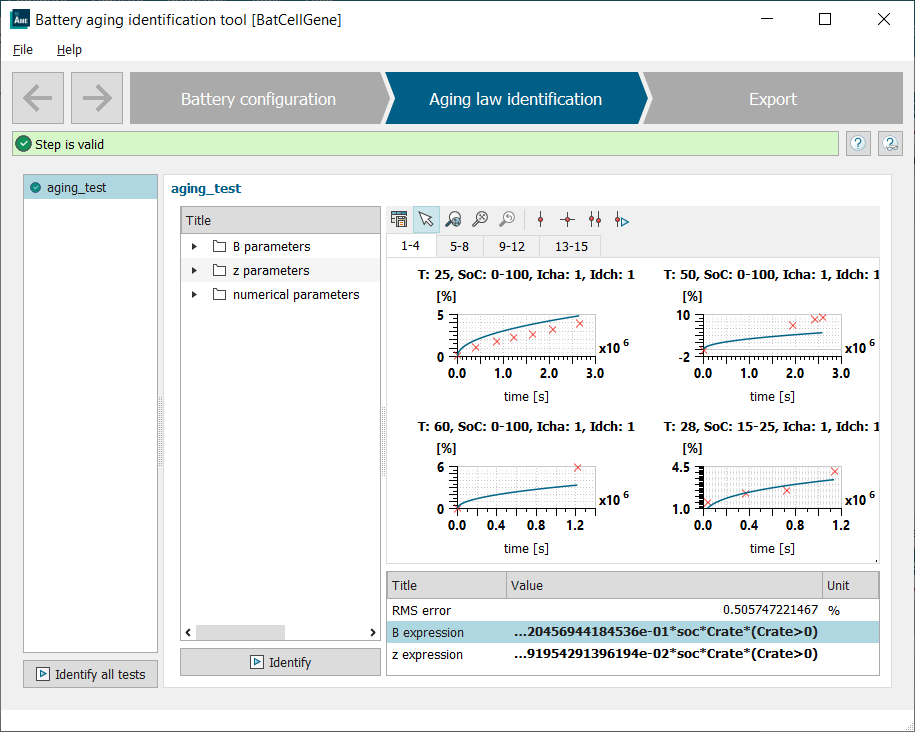

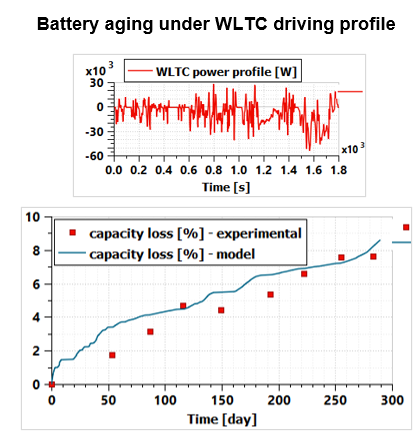

With the new Battery Aging Identification Tool in Simcenter Amesim, Li-ion battery designers and integrators can now quickly set up an empirical law depending on current, temperature, state of charge and time from experimental data in their battery models, to simulate the battery capacity loss under a wide range of operating conditions. This includes low-temperature aging and does not require any prior mechanistic knowledge.

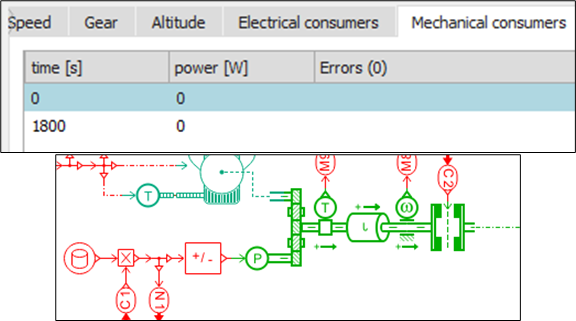

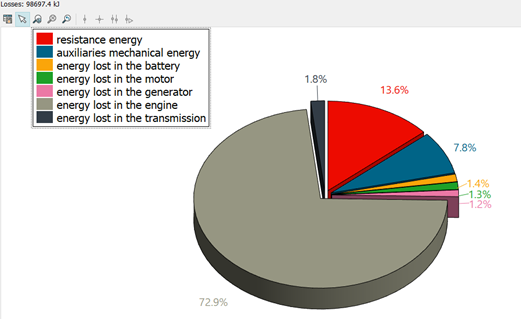

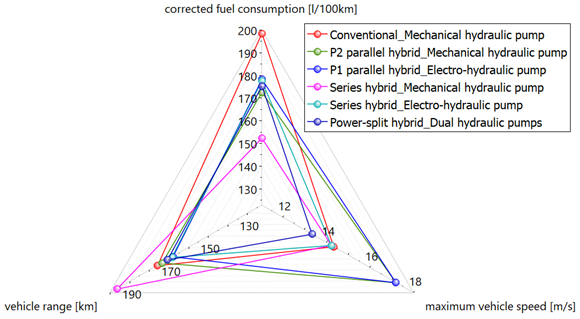

To accelerate the electrification of heavy-duty vehicles, we have expanded the Hybrid Optimization Tool (HOT) with specific features often used in off-highway vehicles. It can now consider driveline inertias and mechanical auxiliaries connected to the engine such as PTO or HVAC in the energy optimization process to get accurate fuel consumption and range estimations. The electrification of Heavy-duty applications is being widely investigated. In this context, the HOT tool is of significant help in identifying the most promising electrification solutions.

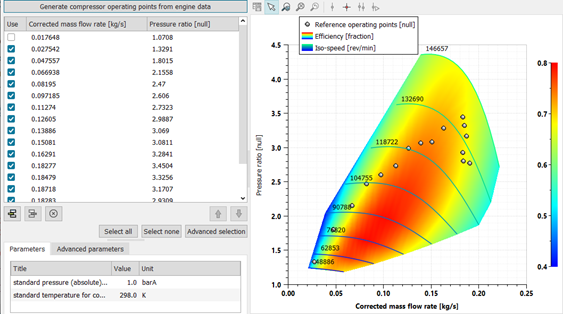

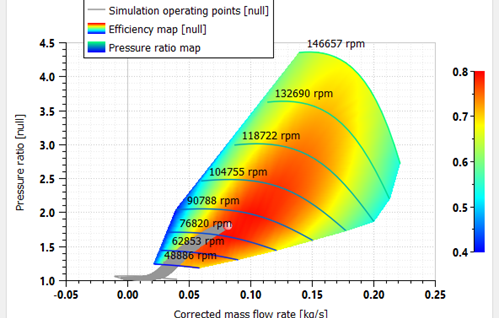

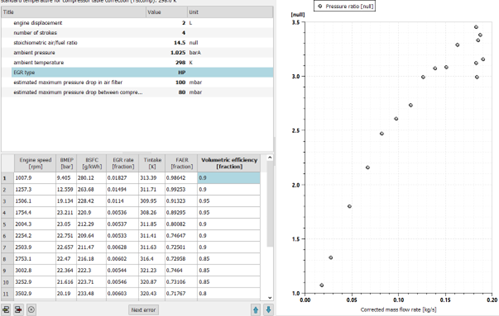

When engineering powertrain concepts using Internal Combustion Engines with compressors, simulation engineers often need to wait for compressor test data or turbocharger supplier’s data. With the new ICE compressor table creator they can now start their simulation workflow for engine design and turbo matching using limited engine data such as full load curve. It gives the ability to generate a full and robust compressor map out of a few estimated engine operating points. The generated map is also fully compatible with the map pre- and post-processing Apps, integrating smoothly into a continuous workflow. Finally, the tool provides geometrical characteristics of the estimated compressor. The tool has been tested and validated on automotive, heavy equipment and marine applications, and on fuel cell compressors as well.

While reduction of energy consumption and emissions is a must, this may not come at the cost of other key attributes that are also considered during all stages of development. With this in mind, Simcenter Amesim 2304 lets engineers better predict thermal cabin comfort and Noise, Vibration and Harshness (NVH) performance as of the earliest design stages.

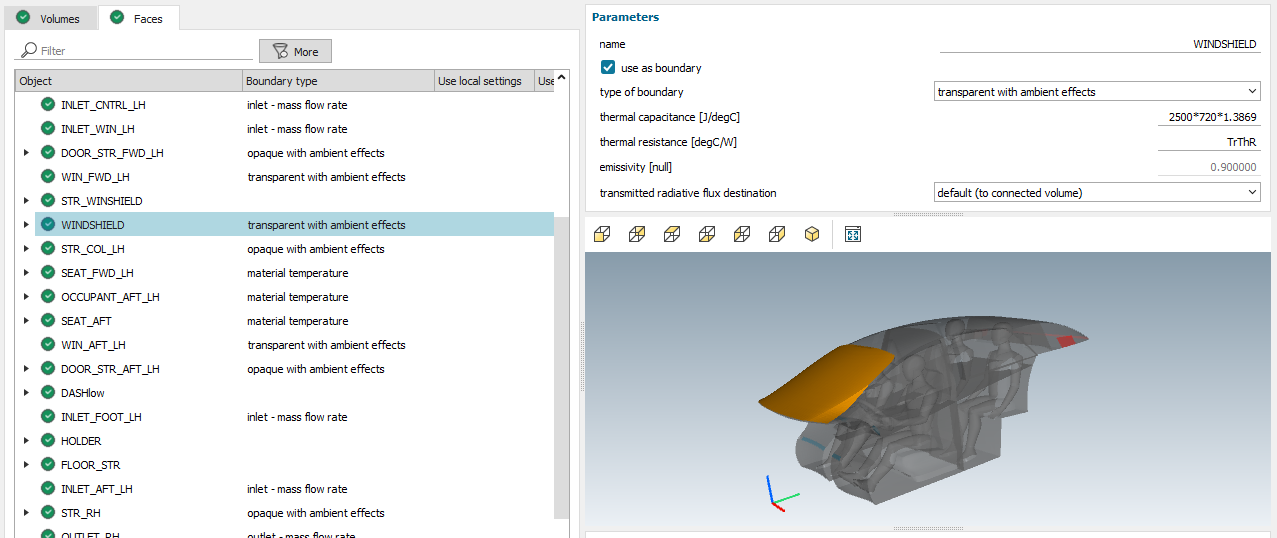

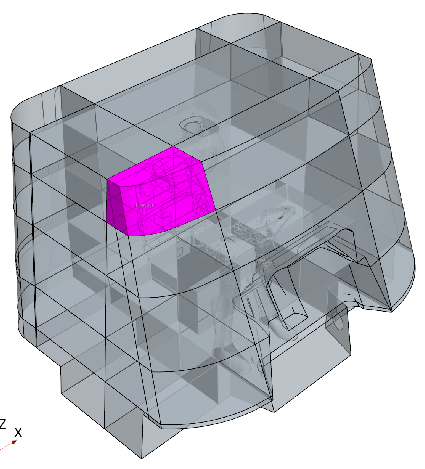

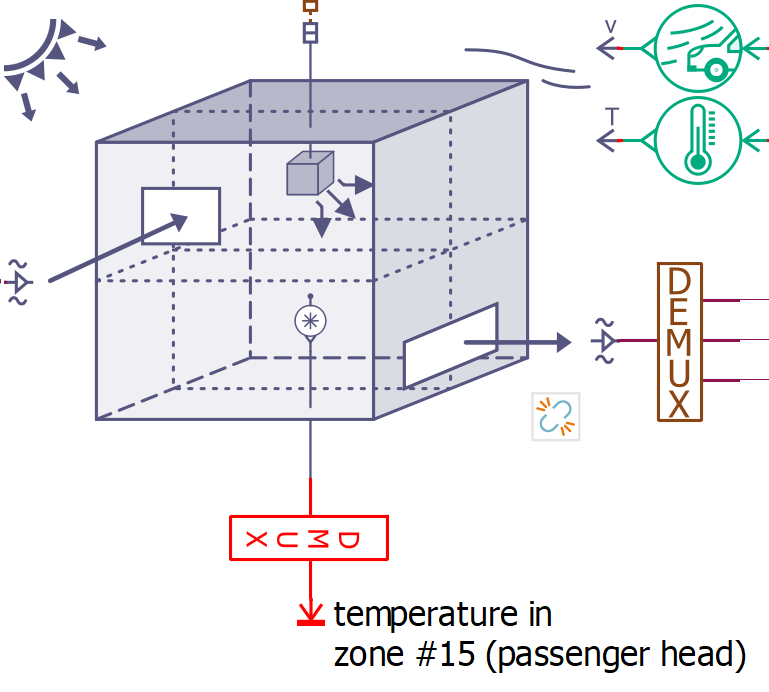

For thermal cabin comfort, the enhancements in the embedded CFD feature now allow an easy way to split imported geometry into temperature zones and the ability to connect thermal masses or to define multi-layer walls. This means that the 1D models’ predictivity will be increased with the consideration of multi-layer walls, human heat generation, heated seats, radiant panels, and with a tailored volume split into temperature zones.

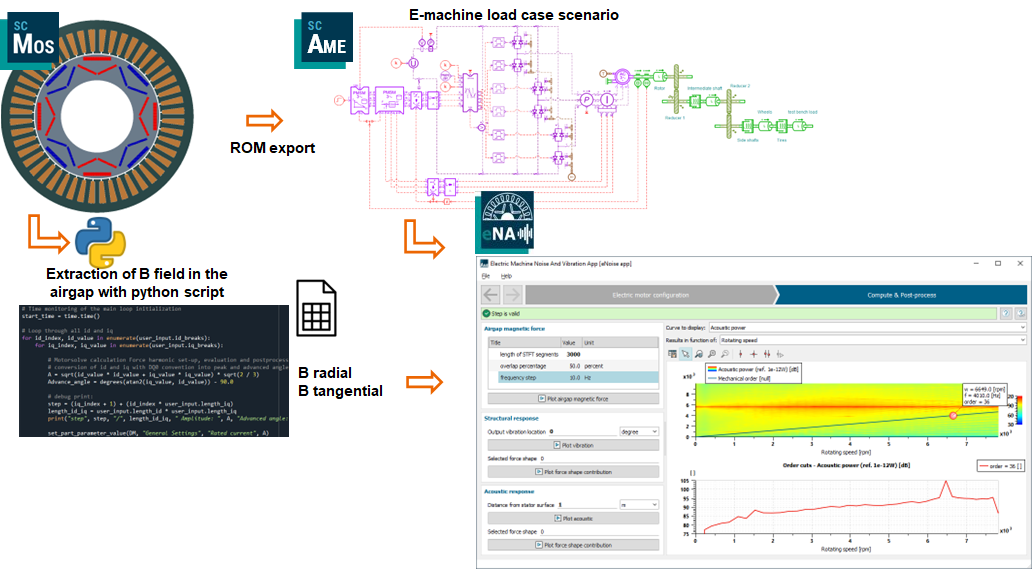

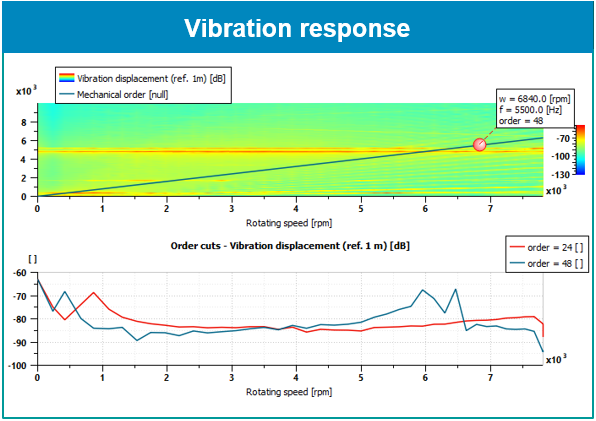

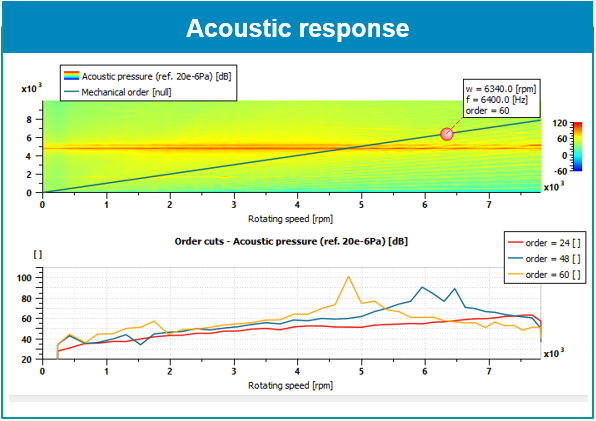

The new Electric Machine Noise and Vibration app is a comprehensive new tool to evaluate the structural and acoustic responses. Linked with the spatial harmonic synchronous machine submodel, NVH can be assessed under realistic load cases including the effects of the control. This means that this tool is of great help when comparing two distinctive designs, assessing the trends as well as potentially problematic frequencies and giving the possibility to virtually evaluate fixes.

The usage of hydrogen for clean mobility is on a rise, and Simcenter Systems Simulation facilitates this acceleration with new features supporting the entire hydrogen value chain including production, storage, distribution and usage.

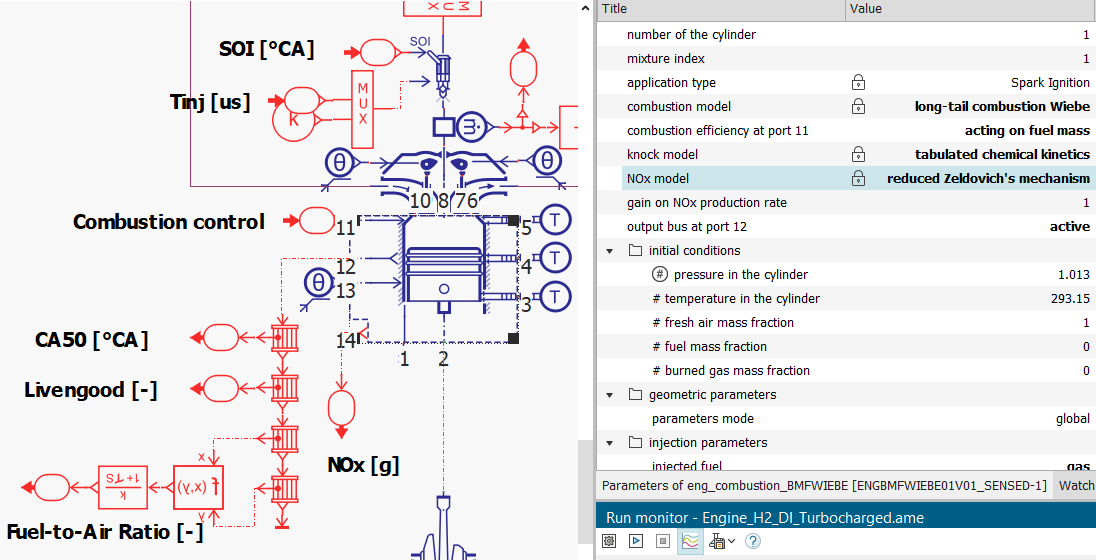

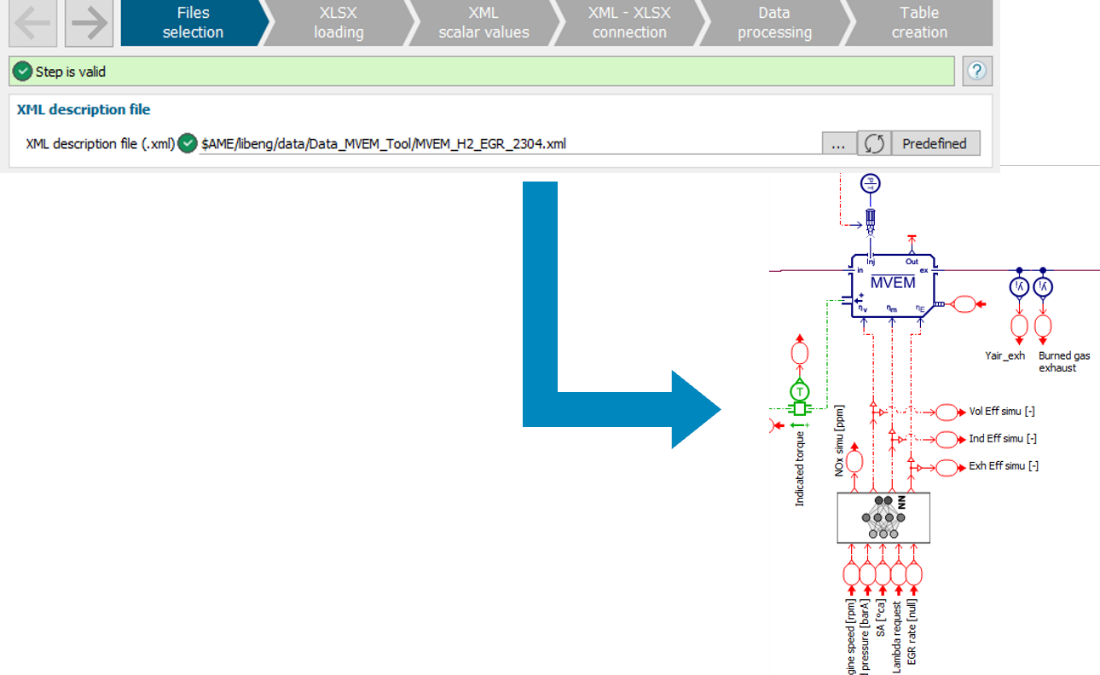

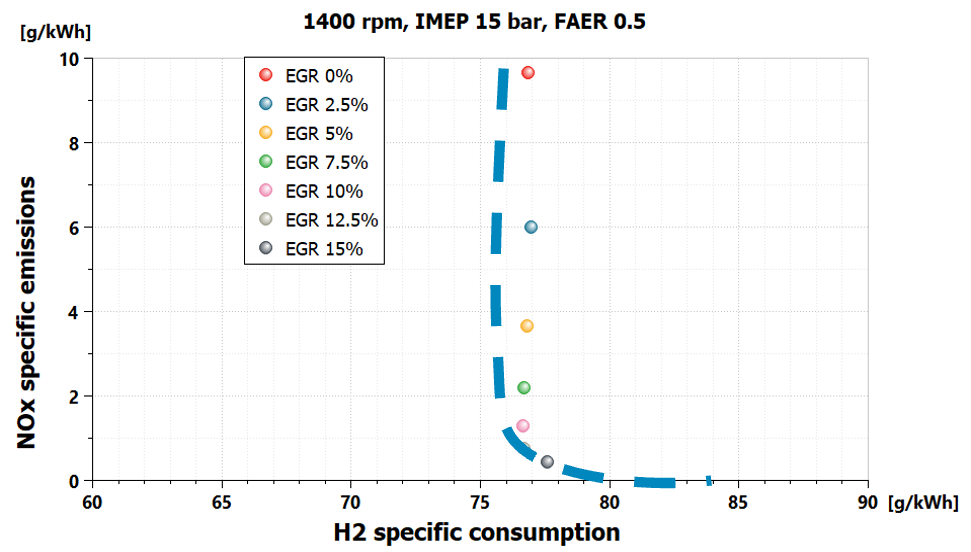

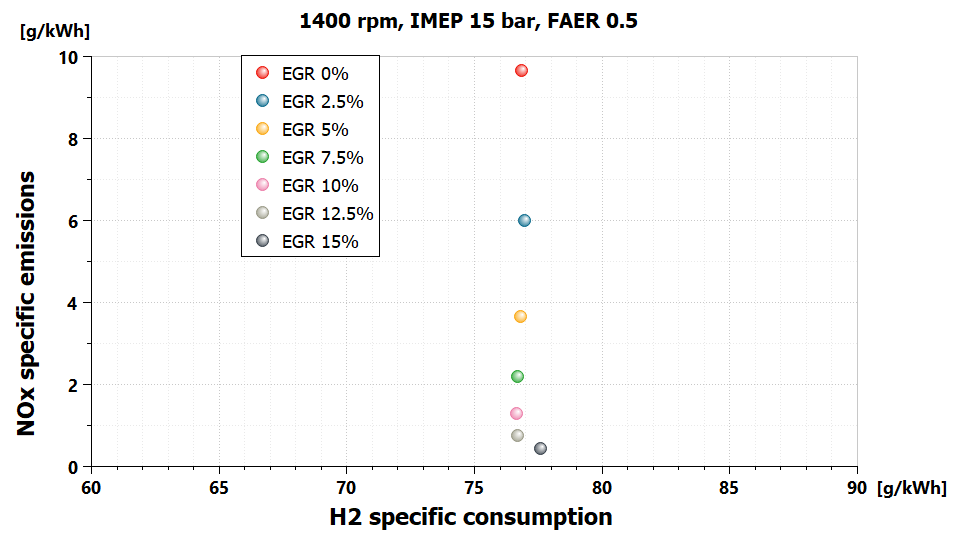

The new H2 engine design workflow in Simcenter Amesim 2304 will support engineers working on hydrogen engine development who are facing tight deadlines in combination with limited available data in the early development stages. This new feature can combine several modeling approaches that are available to simulate a hydrogen combustion engine and combine them into a continuous workflow. Based on different design parameters it can predict NOx emissions and knock, and the possibility to implement a mix between data-based and physics-based modeling approaches to quickly reach tangible results. It allows users to perform hydrogen internal combustion engine design and calibration at any point of the development cycle

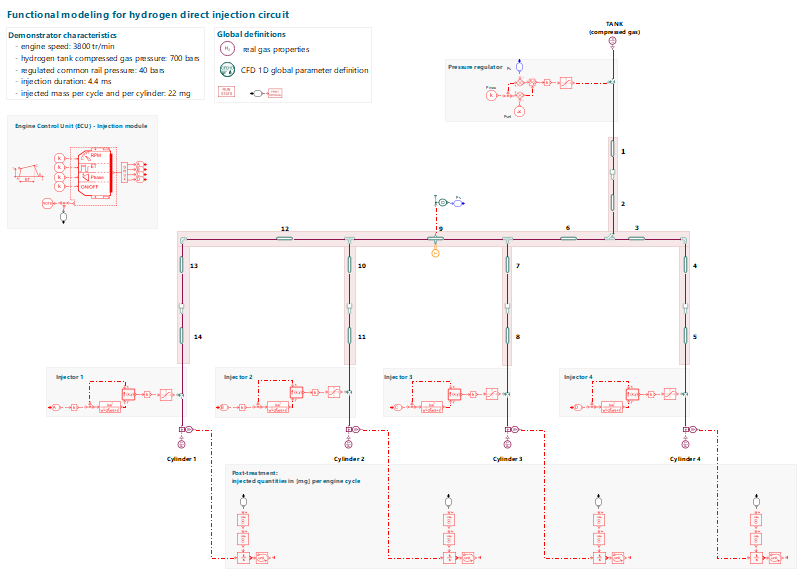

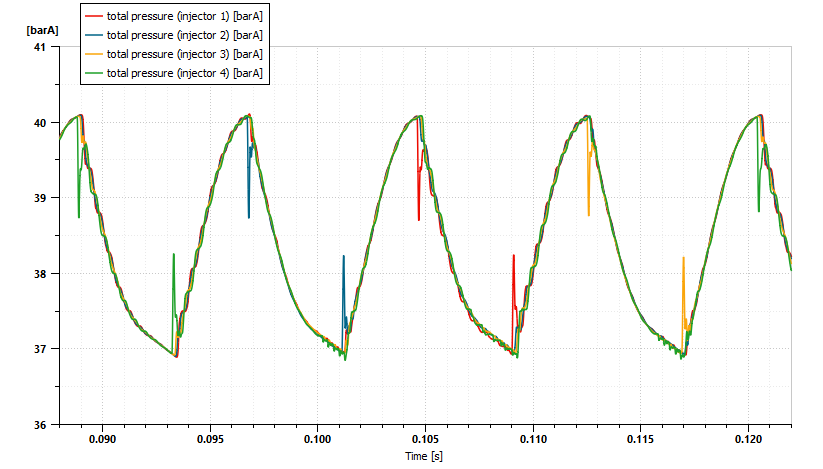

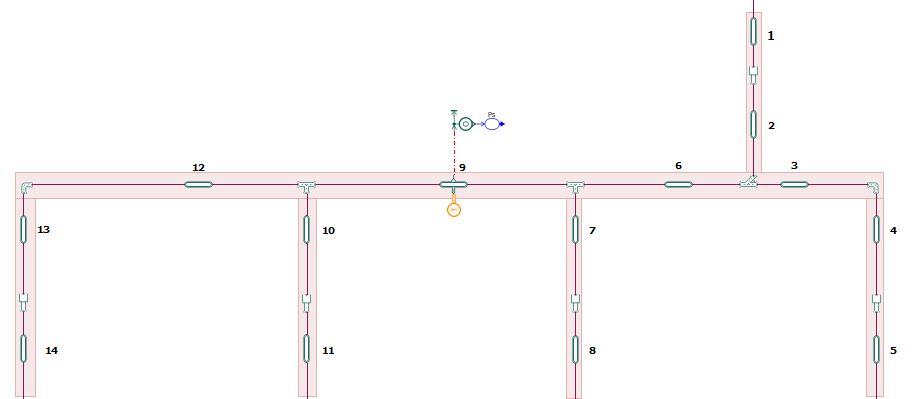

The new hydrogen direct injection system demo in Simcenter Amesim 2304 allows users to use all the methodologies and tools used to model and analyze diesel of gasoline injection systems to study hydrogen injection systems as well.

Towards a green and sustainable supply of energy

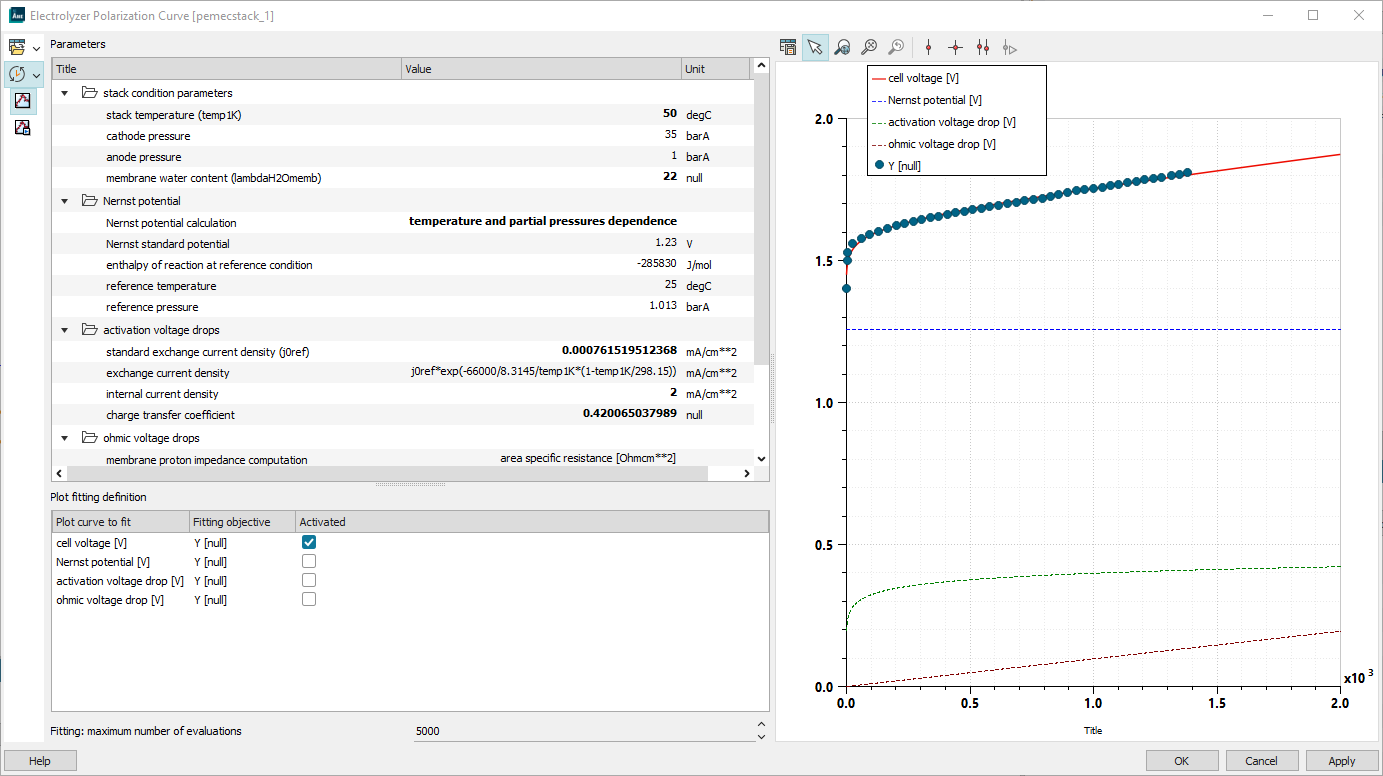

To simulate the production of hydrogen, the new PEM electrolyzer feature in Simcenter Amesim includes a predictive model based on electrochemical equations together with a dedicated polarization app. This new component can be used as a single component to produce hydrogen, or in combination with solar panels, wind turbines, PEM fuel cells, batteries or hydrogen storage. This gives the user endless possibilities to build a representative model of a complete hydrogen process including production, storage and re-use.

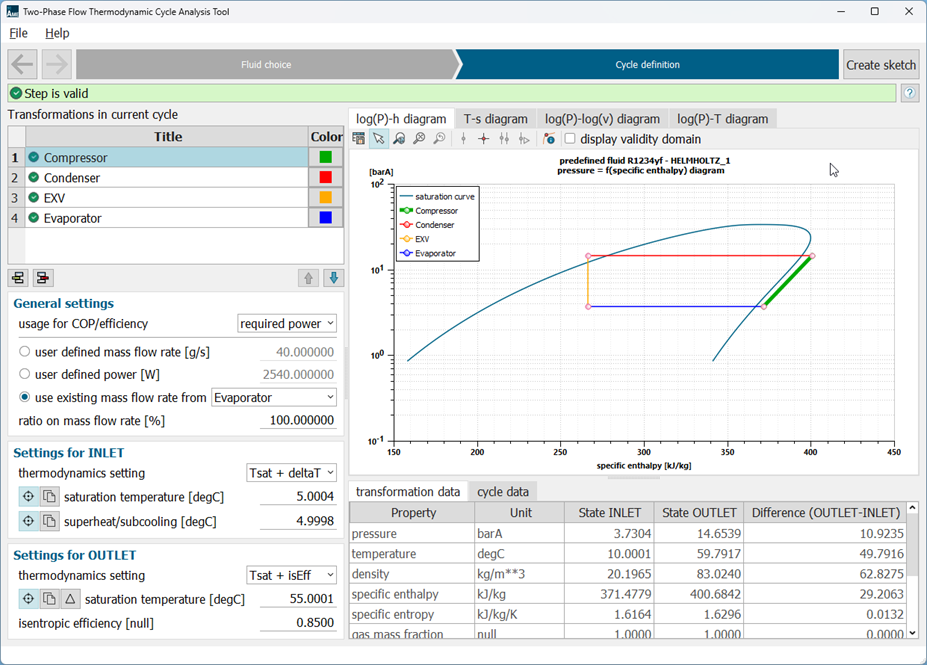

With Simcenter Flomaster 2304, new features become available to our users that work on energy capture and storage, for example in chemical, process, or energy & utility industries.

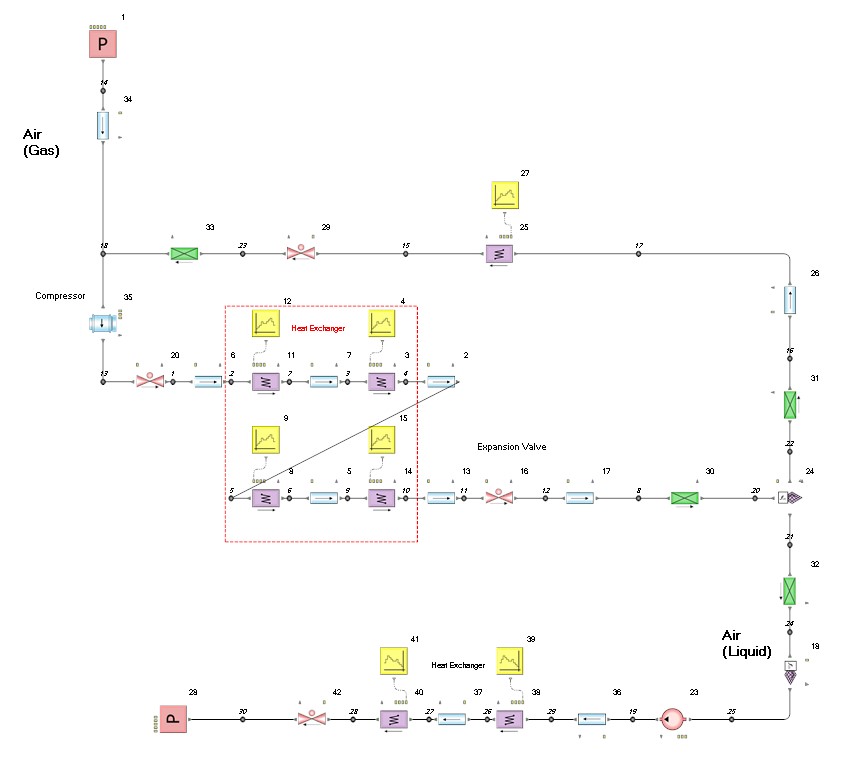

The gas liquefaction process as a method to store gases like hydrogen and air, and transport or reuse it by re-expansion at a later stage is now supported by Simcenter Flomaster 2304. It offers the capability to accurately simulate this process through tanks, separators, and demister membranes, further building on the existing two-phase catalog of components. Users can now build a complete model of the liquefaction system from the compression back to the expansion through turbines. The new tanks and separators also fully embrace the Simcenter Flomaster design philosophy of creating an initial model with limited data while adding more complex behavior as more data becomes available. In the early stage, a simple homogeneous separator could be created, while at later stages full heat transfer and demister geometries can be applied to build up a more accurate model.

This capability has been developed to help users understand the energy involved in the compression and chilling of gases to become liquids and then later returned to their natural gaseous state to release energy.

For energy capture using the molten salt technology a new capability has been developed in Simcenter Flomaster 2304 to connect advanced tanks to two-phase models. It lets users accurately simulate the molten salt process and build a complete process in a closed loop that harvests energy from an industrial process or from a farm of solar reflectors, and store it long-term as molten salt. Due to the advanced tanks being used for this, the complex heat transfer effects can be modeled along with the interstitial heat transfer inside the tank. In doing so a highly complex model of the molten salt system can be created that enables users to understand the long-term storage effects of the salt and the viability of the energy therein.

Platform improvements that increase productivity

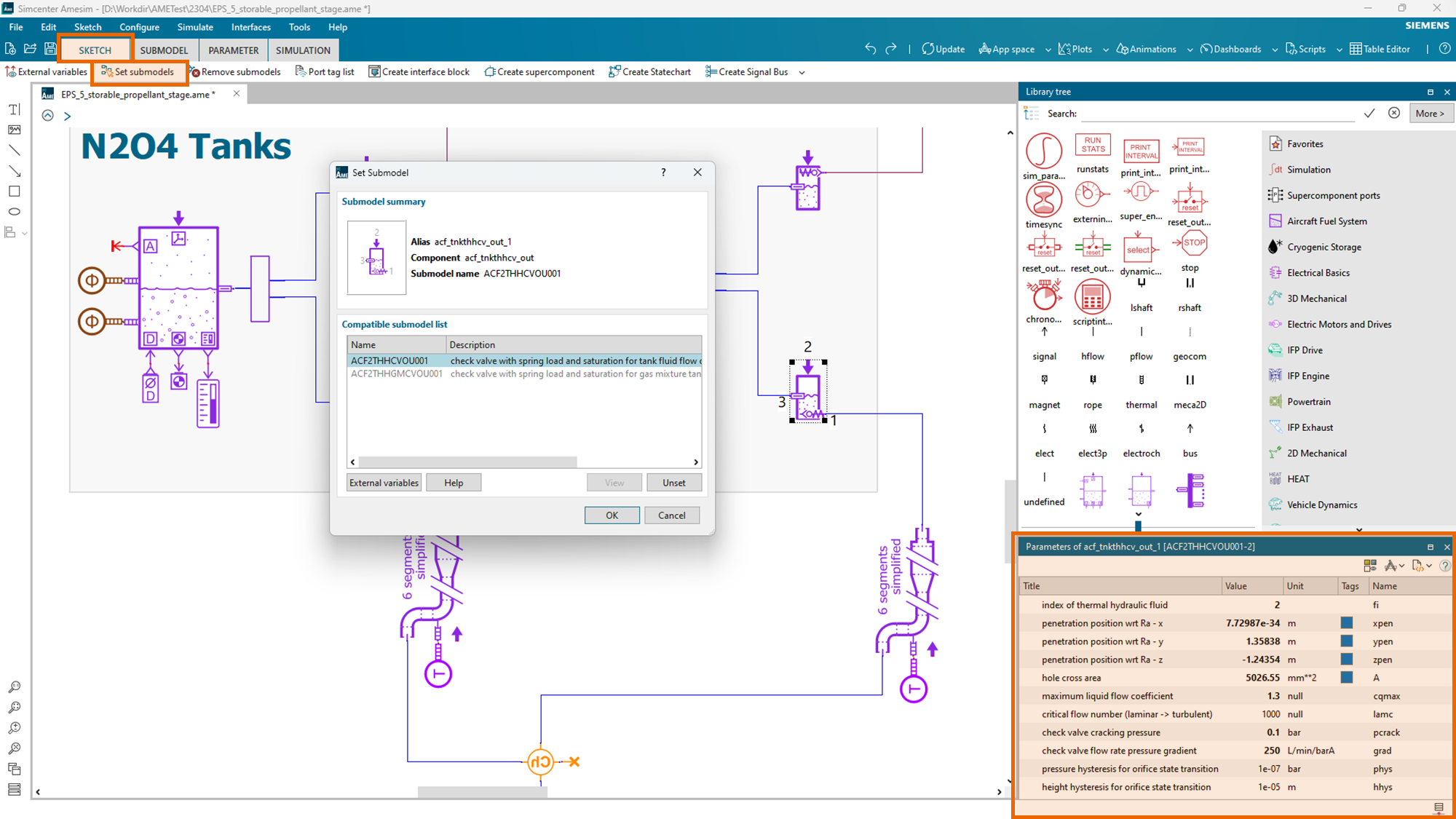

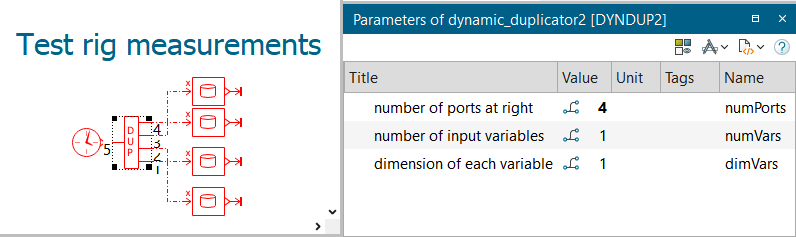

The new early model parametrization feature in Simcenter Amesim 2304 lets you start setting model parameters as early as possible, even during sketch building by offering a shortcut for setting key known submodels and parameters during the construction of a model. This means that users can more efficiently go about their modeling activities and drastically shorten the feedback loop of sketch-building and parametrization.

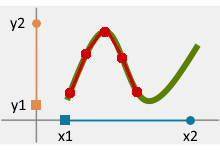

The new Graph Digitizer in Simcenter Amesim is a great new feature for simulation engineers who must build their models using specification curves provided in suppliers’ catalogs, without having access to full datasets. It can retrieve the numerical values from a specification curve in a picture and export the data in tabular form. This means that engineers can test components from suppliers’ catalogs in their models even if the characterization data is not fully accessible.

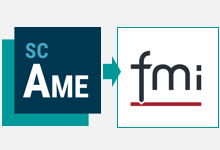

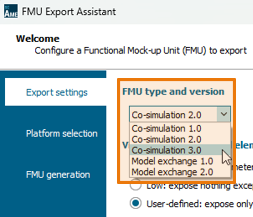

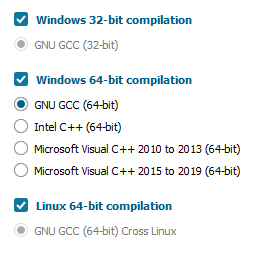

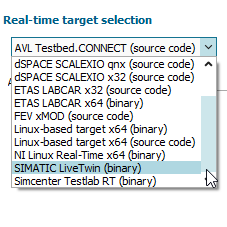

With this new release, users benefit from the latest version of the FMI standard when deploying Simcenter Amesim and Simcenter Flomaster models in collaborative software environments with different tools. The new FMI 3.0 co-simulation export capability in Simcenter Amesim and Simcenter Flomaster offers a streamlined way to package models with their best-in-class solver as FMUs. This means that numerically validated physical models, possibly hybridized with Modelica blocks, statecharts, neural networks or previously imported Simulink models, can be shared easily within the most recent FMI 3.0 compatible software ecosystems.

The export of FMUs for co-simulation offered by Simcenter Amesim and Simcenter Flomaster confirms the prominent role played by Siemens Digital Industries Software within the FMI Steering Committee, and its commitment to quickly deliver the latest powerful FMI features to its customers.

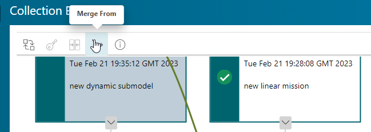

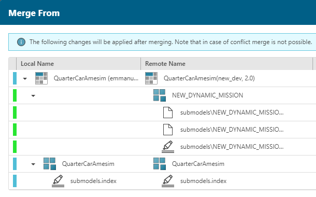

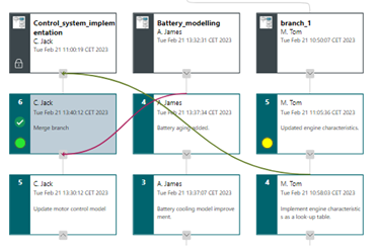

To improve collaboration, the new Merging feature in Simcenter Client for Git offers the capability to merge modifications from other branches when there is no conflict. It is now possible to merge modifications introduced in a different branch into your local version and visualize this in the graphical version history. This only applies when there is no conflict between versions.

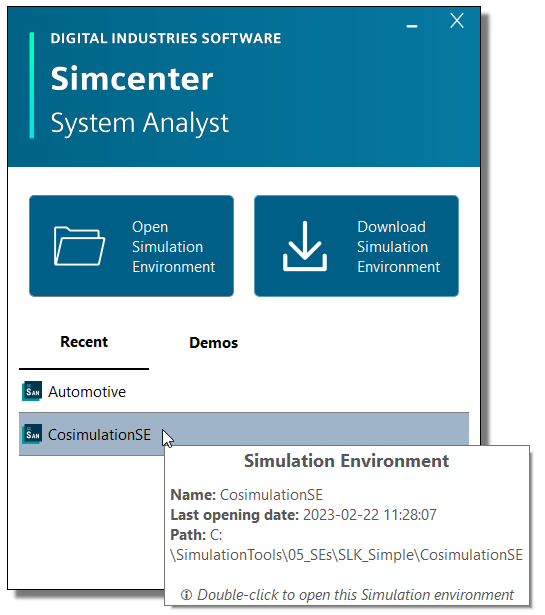

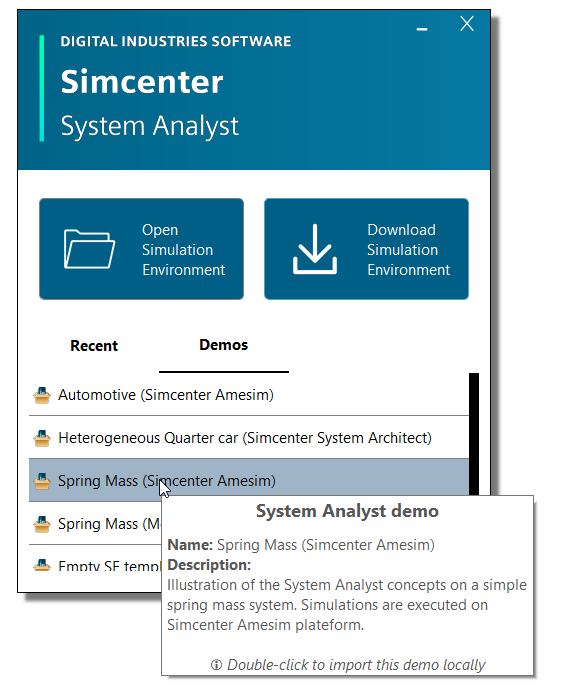

For Simcenter System Analyst customers it is now faster to create a new Simulation Environment and share it with System Analyst end users. The new Simulation Environment selection UX in Simcenter System Analyst and in the View Editor companion tool allows to create a single Simulation Environment without creating a gate file, to use the demonstrator without modifying the Simcenter System Analyst installation folder and to Export/Import the Simulation Environment pack files through Xcelerator Share.

For the Simcenter System Analyst end users, the new Simulation Environment selection UX offers a shortcut to the 5 latest Simulation Environments used and the automatic set-up of the server connection from a local Simulation Environment. This means that there are fewer mouse clicks needed and it offers a more intuitive process and modernized Simulation Environment selection pages to open the Simcenter System Analyst application.

Conclusion

With the 2304 release for Simcenter Systems Simulation our developers have again made big efforts to support our users in their daily engineering activities. The new releases part of Simcenter Systems Simulation 2304 are now available for download on our Support Center. Check out our blog posts and how-to articles for more news and helpful information!