What’s New in Simcenter Flomaster 2019.1

Simcenter Flomaster 2019.1 is the latest feature rich release that helps users to enhance their productivity and enables new physical phenomena to be modelled. The complete list of features can be found in this webinar or by downloading the latest datasheet.

Here I would like to talk about my favourite enhancements.

Fluid Systems Dynamic Attitude and Accelerations

Not all fluid systems are still. The accelerations caused by the manoeuvres of an aircraft or of a submarine force the fluid in piping systems and tanks to move from one point to another. These dynamic effects must be taken into account when designing fluid systems to avoid major failures. Simcenter Flomaster 2019.1 introduces dynamic node elevation that account for these dynamic effects. The three-dimensional location of each point of the system is automatically imported from 3D CAD using CAD 2 Flomaster. Transient manoeuvres, such as an aircraft turning or a submarine emerging or submerging, are defined as time variations of attitude and accelerations on newly added environment model components.

Simcenter Flomaster Dynamic Node Elevation. Aerospace example

Simcenter Flomaster Dynamic Node Elevation. Aerospace example

Multi-arm tank enhancements have also been introduced which provide the ability to model any orientation for the pipe lines connected to the tanks while connecting the tank to any number of liquid and gas pipe lines. Finally, the flow of the fluid between the tanks and through the piping system can be effectively visualized by animated vectors that allow users to easily and quickly understand the dynamic behaviour of the system.

You can see a video showing this capability in action in my last blog entry.

Simcenter Flomaster Dynamic Node Elevation. Submarine example

Simcenter Flomaster Dynamic Node Elevation. Submarine example

Network Result Validation

System engineers need to make sure the systems they are designing meet specific requirements and constraints. These may include minimum and maximum flows, pressures, velocities and temperatures. Checking all these requirements and constraints after a simulation has run can be very time consuming.

With Simcenter Flomaster 2019.1 it is now possible to define requirements and constrains for a system. If the requirement is met, it is highlighted in green, and if not met, it will be highlighted in red. This gives the user all the necessary information at a glance. If a requirement is not met, it is possible to locate where in the system the problem occurrs (by automatically collecting all the problematic nodes and components) and further investigate the route cause of the problem.

Simcenter Flomaster Network Result Validation

Simcenter Flomaster Network Result Validation

Wave Speed Calculator

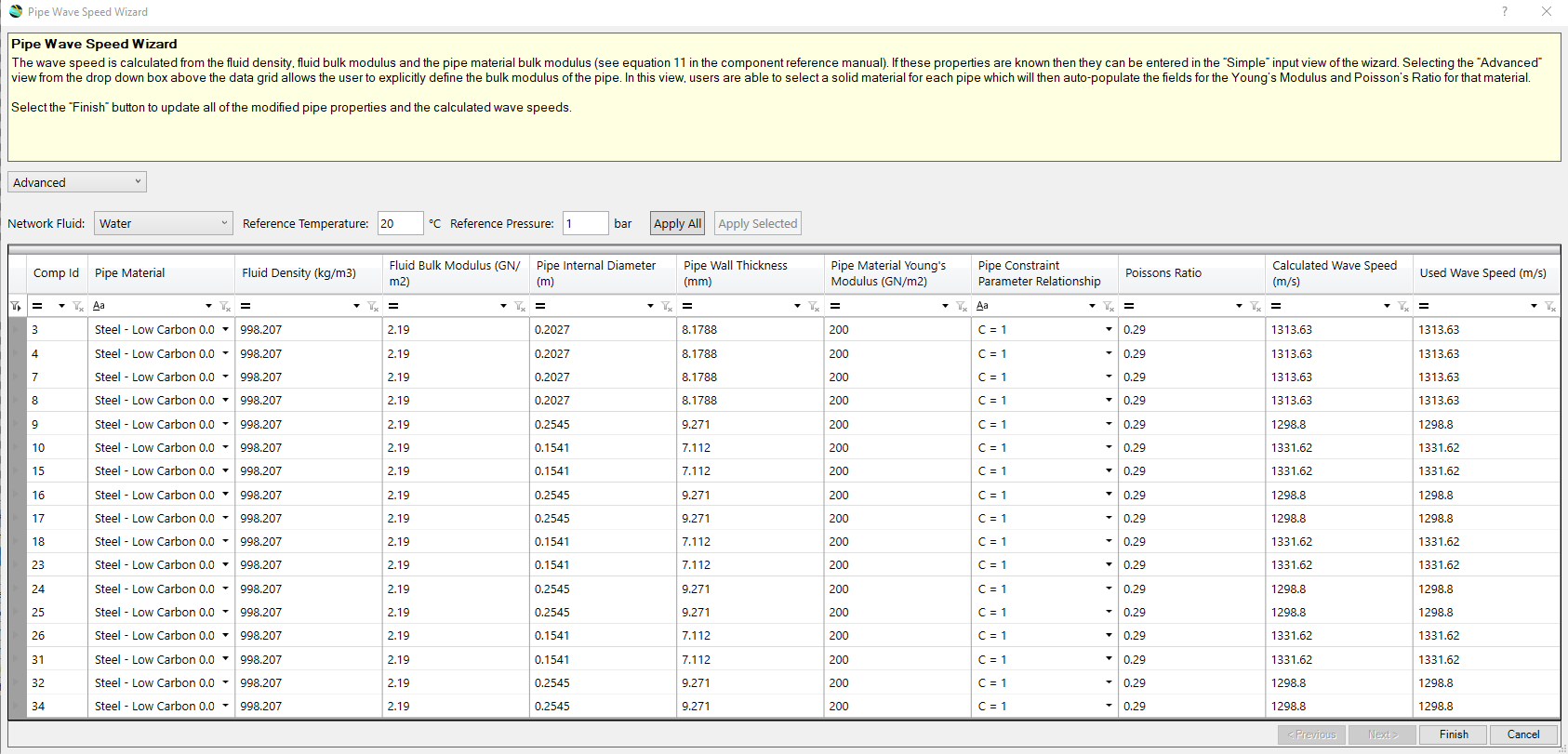

While hoping that a system will always work at its best, system engineers need to plan for the worst. In this framework the studies of emergency and failure scenarios are crucial. Pressure surge or water hammer effect is the most important one because it can cause severe damages to the system as well as major security issues. Pressure surge can be caused by a pump trip or an emergency valve closure. The most important information to be retrieved from a pressure surge simulation is the pressure peak during the surge phenomenon. A highly accurate computation of the pressure peak can be achieved if no numerical or artificial diffusivity is introduced in the simulation. Simcenter Flomaster achieves this target by implementing the Method of Characteristic in a special way so that no numerical diffusivity is introduced. The toll that needs to be paid is that the user needs to input the wave speed in the pipes. While this computation is not complex for a system engineer, it can for sure be time consuming. To increase user productivity (and make their life easier), Simcenter Flomaster 2019.1 introduces a wave speed calculator to compute the wave speed for each pipe in the system. The required data is automatically populated when available in a component so that minimal data input is required. Then the calculated wave speeds is applied to all of the pipes. The tool is designed to give the user the maximum level of control since each value can be modified.

Simcenter Flomaster Wave Speed Calculator

Simcenter Flomaster Wave Speed Calculator