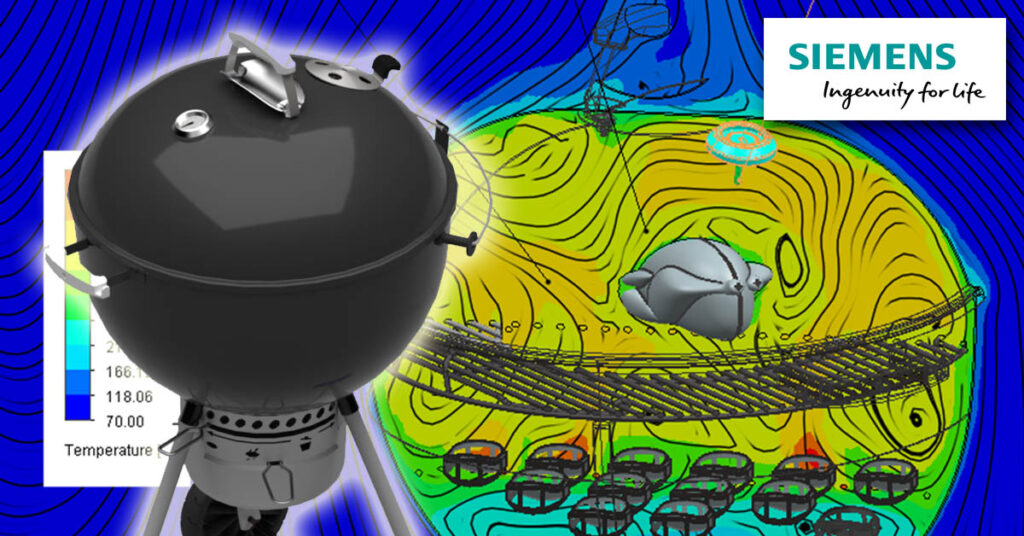

Thanksgiving turkey analysis in Simcenter FLOEFD

It’s been a while since my last blog as it’s been a very busy year. One blog topic I’ve been wanting to do for a while is look into roasting turkeys. Let me explain. My wife is not very good at cooking American food. Well I likely don’t need American in that sentence. So when we moved into our house, and started our family, one of the issues that I needed to address at a previous thanksgiving was how to cook a turkey. You can find a ton of recipes and advise for this on the internet, or on TV, but nothing is very clear. Like stuffing, my mom always put it inside the turkey, but TV show hosts say it leads to dry turkey because now hot air can’t get to the inside of the bird and cook it faster, and you have to cook the stuffing to a safe temperature and by that point the turkey breast meat is dry as a bone. Well, I remember loving eating turkey on thanksgiving growing up, so it couldn’t be that dry. One point here, I’m likely not the best person to judge how dry meat is, as I prefer all meat well done. Much better to be overcooked then undercooked in my opinion, which I know is not shared by many others.

Beyond the cooking advice, there was also the decision on the cooking pan. Did we need to buy a roaster pan, or would a throw away aluminum one do? If you buy a pan, well there are steel roasters, or aluminum roasters, ect, all with different prices and all saying the cook better then the other. People on TV say you need a roasting rack, so air can get under the bird, and so it doesn’t sit in all the liquid making that meat all mushy. Well some carrots/celery/potatoes can be used to prop up a bird to keep it out of the drippings. It won’t help with airflow, but I have my doubts on this whole airflow argument. If you do look at racks, there are a bunch of different racks available. Some only hold the turkey up a little, some hold it up pretty high off the bottom of the pan. Does higher mean better airflow under the turkey? If there is too much airflow, won’t that dry out the skin? All these airflow issues also depend on the oven. If it’s a convection oven and has a fan blowing hot air at the turkey, well that’s a completely different environment then having natural convection air currents (hot air rising, cooler air sinking) in the oven.

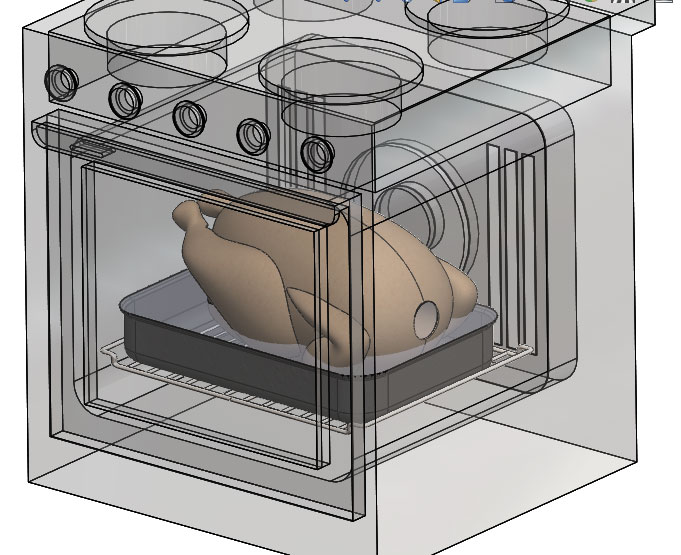

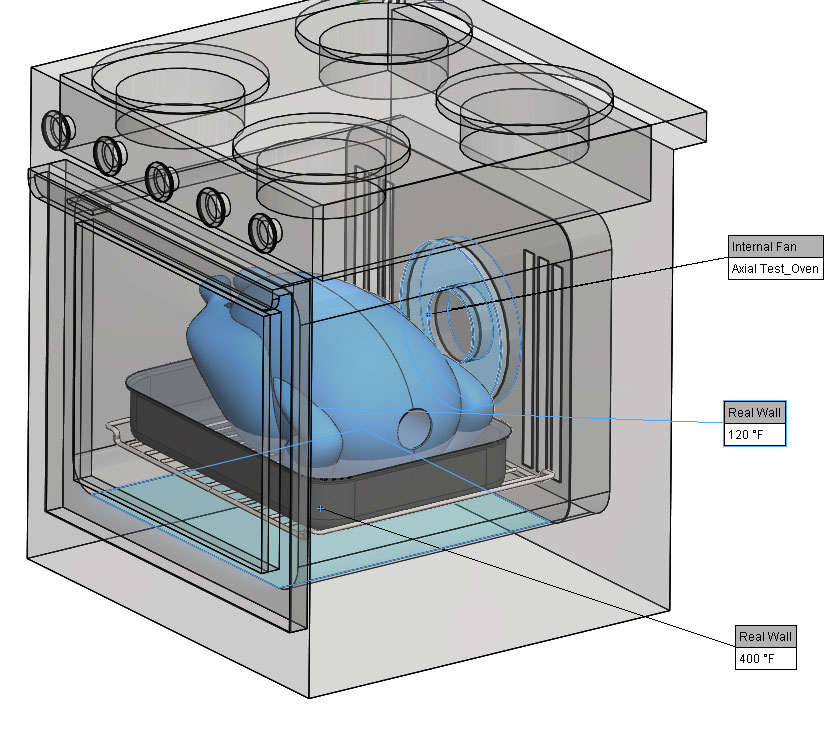

So thanksgiving #3 is coming up for us in our house, and I have some empirical (experimental) results from the last two, but not enough to make my conclusions. I would prefer not to have hit or miss thanksgiving dinners for the next 10 years while figuring out what is important and what isn’t when it comes to roasting a turkey, so I built a computational fluid dynamics model in our Simcenter FLOEFD software to answer some of these questions. I believe this will be a multipart blog, as every time I answer one question, I end up having more. Below is my model. I got the oven CAD from my good friend and colleague John Wilson. I found the turkey and the other CAD parts on www.grabcad.com. For this model, the rack height is set to 0.4 inches above the bottom of the pan. Discuss amongst yourselves if you think that is a reasonable starting point in the optimum rack search.

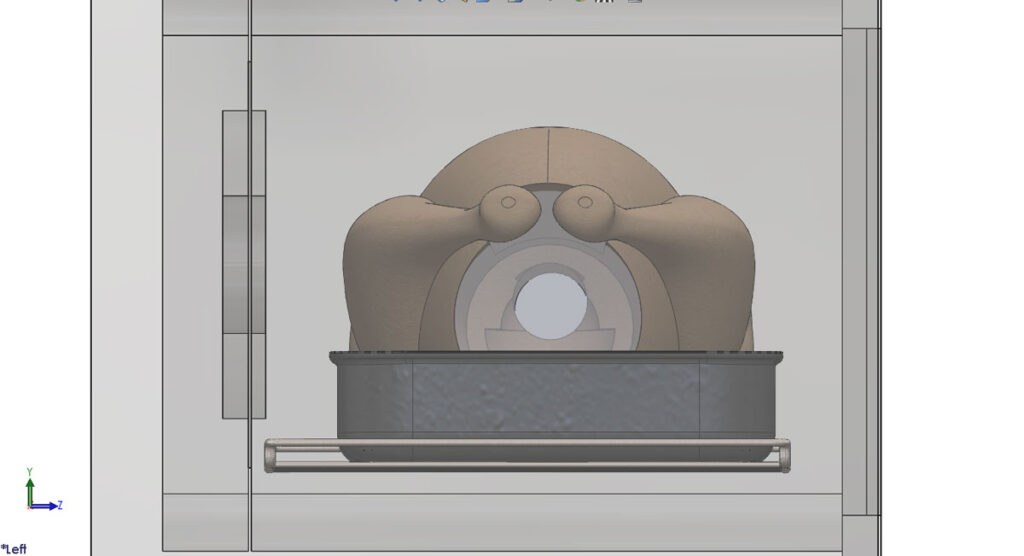

The turkey wasn’t quite correct, it was just one solid block. It didn’t have a cavity for stuffing or a neck cavity, so I just eyeballed those and made some cuts. I wasn’t going to buy a turkey to take measurements Now, as one of our most important questions is airflow amounts through various spaces (into the cavities, under the turkey), I created some objects so we could track this data. The oven was setup as a convection oven, in that there is a fan at the back pushing air horizontally over the roasting area.

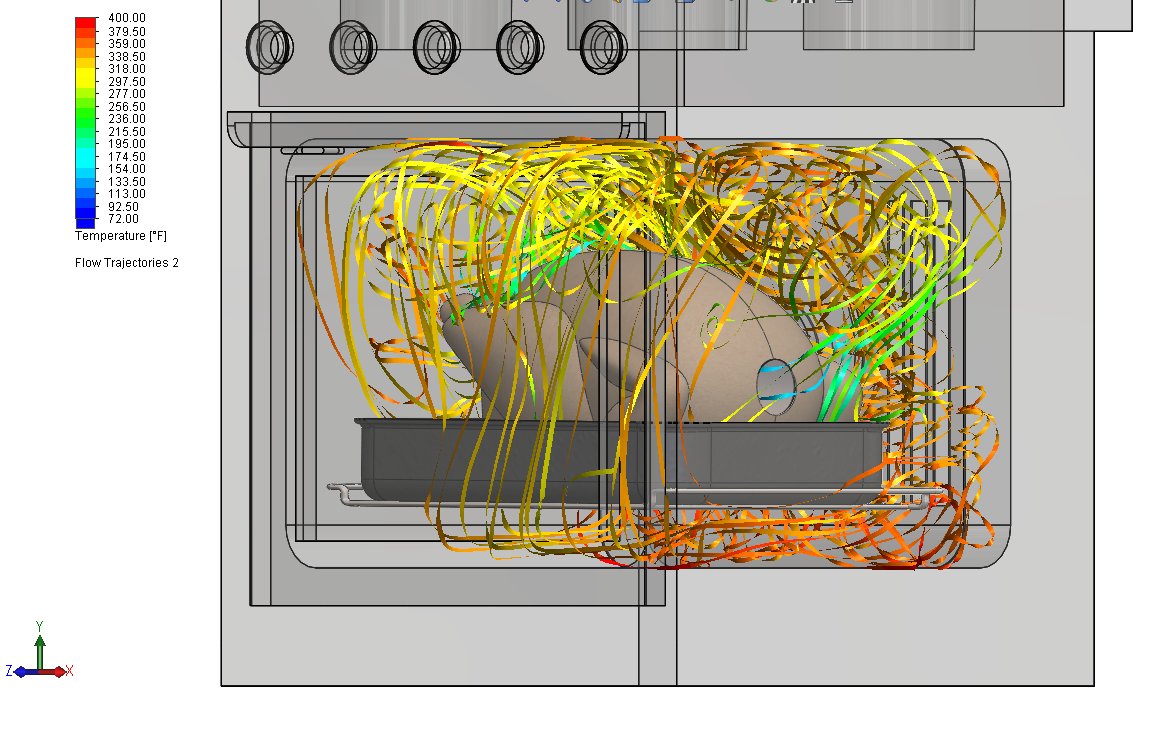

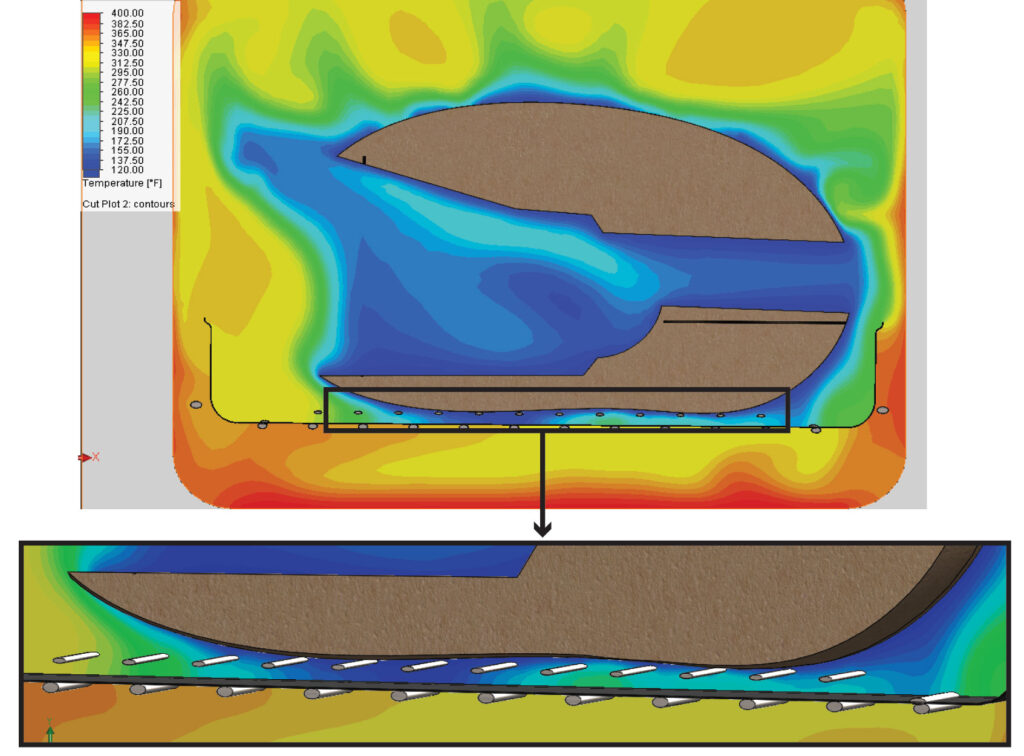

This model was run as a snapshot in time, meaning I set the turkey temperature to some not quite fully cooked yet temperature (set to 120 F). The oven temperature was set to 375F, with the heating elements being slightly hotter at 400 F, at the bottom of the oven.

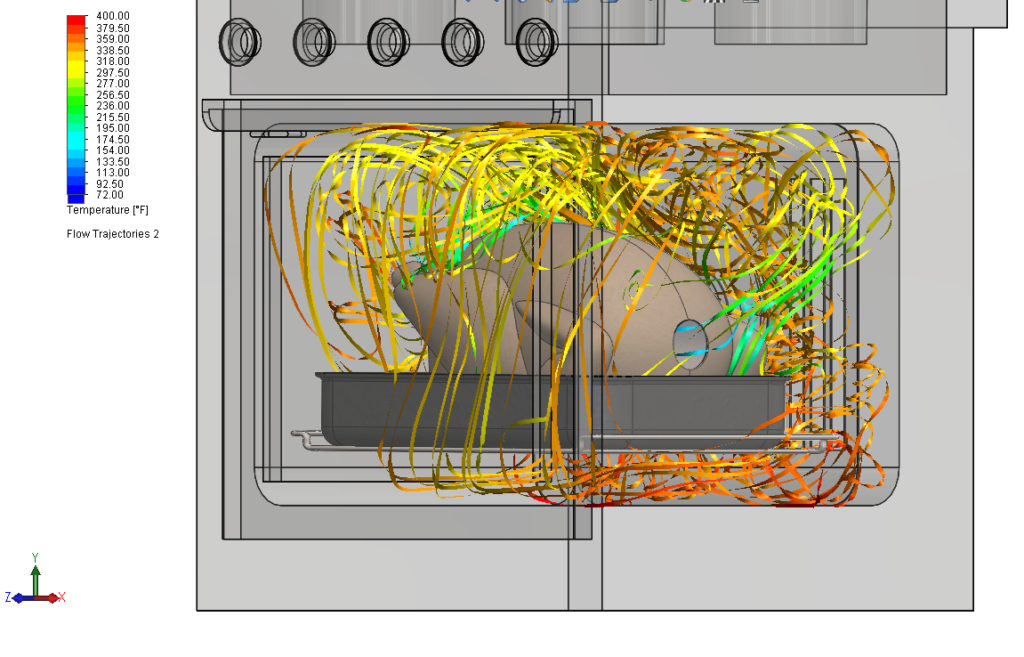

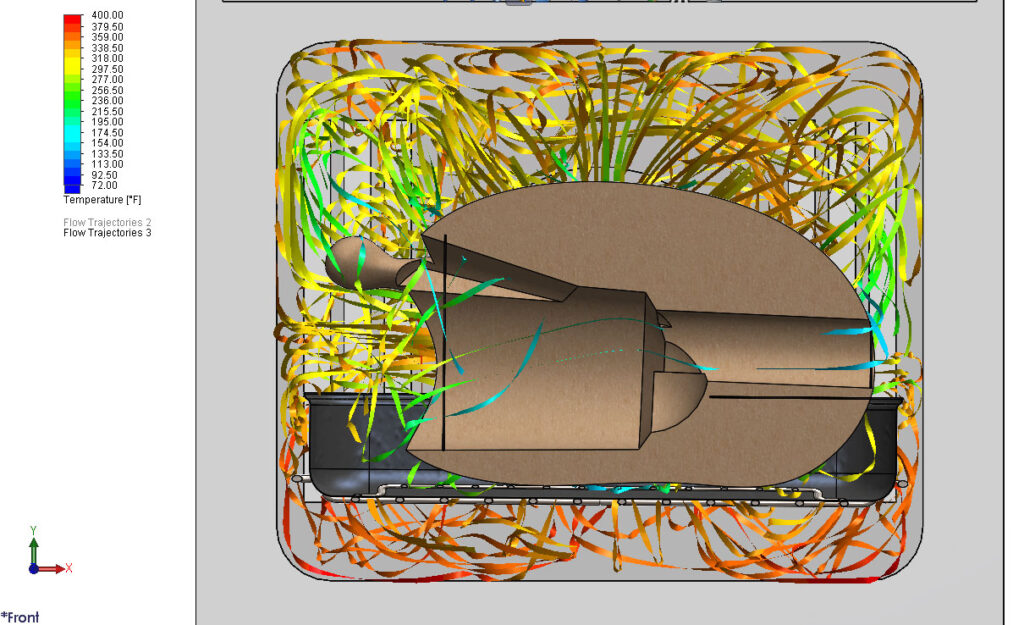

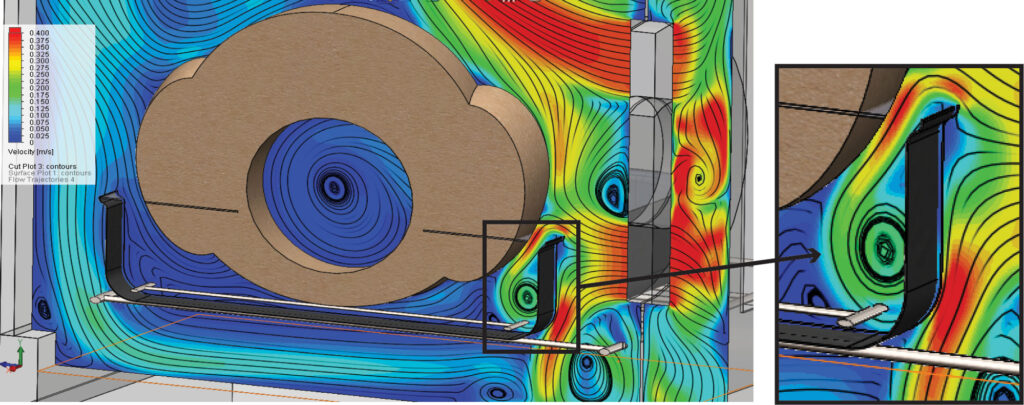

Lets start by looking at some streamlines. These are like those smoke streams shown in car commercials when the car is in a wind tunnel. They just show where the air is going. I set the fan as the starting point of these streamlines. I know the streamlines are quite chaotic, but there is information we can get from this. If we section the model, we can see into the roaster and into the cavity of the turkey. Compared to the streamlines outside the turkey, there isn’t a lot of air going into the roaster and under the turkey. And there is even less going though the turkey. This is what I expected, especially for the cavity airflow. The fan is pushing the air across the width of the turkey, not along the length of the bird. The air would have to flow around the turkey, then make a 180 degree turn to flow into the cavity, which there is no reason for it to do. Since turkey’s are so big, they can’t be oriented in the direction of the airflow from the fan.

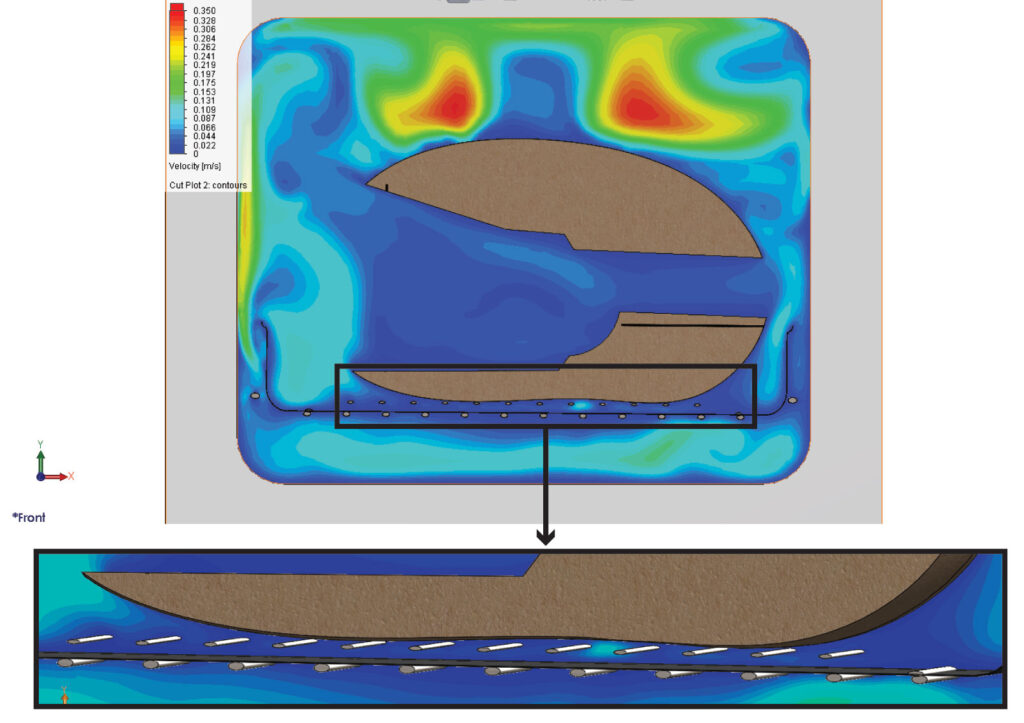

If we look at a contour plot of velocity, going through the middle of the turkey and oven, we see that the airspeed through the turkey and under the turkey is very low, while the airspeed above the turkey and under the roasting pan is more significant. What constitutes very slow air? What I like to compare it to is, if we didn’t pay for a fan, and had a natural convection oven, the typical airspeed for that is about 0.2 m/s. So we aren’t getting any improved heat transfer because of this fan, as the majority of the surface area of the turkey is experiencing airspeed less then 0.2 m/s.

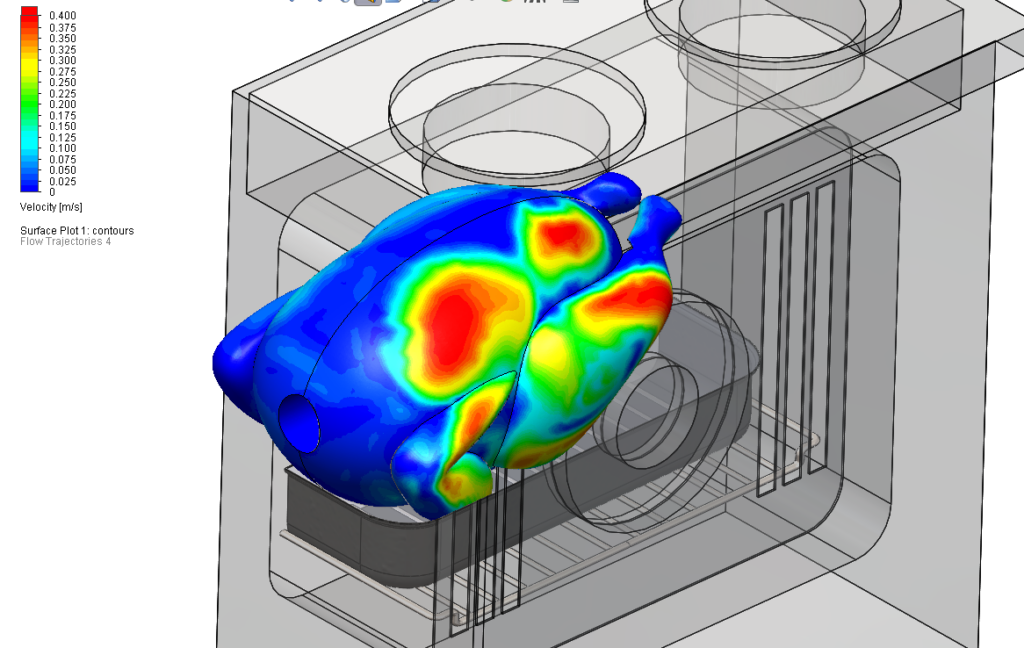

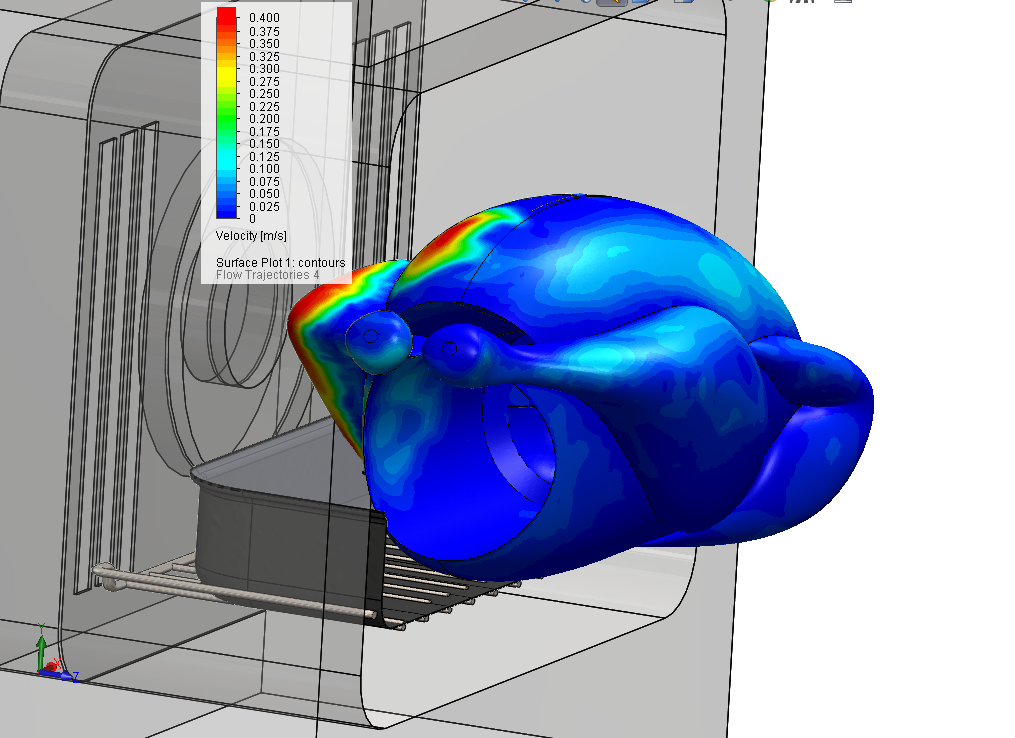

To really see this, lets look at a surface plot of the velocity near the surface of the turkey. I split this up into 2 images, one looking at the turkey surface close to the fan, and the other looking at the opposite side. There is a clear difference here, and the result of this is that one side of the turkey will cook much faster then the other (or dry out faster), if the turkey isn’t rotated periodically. Faster air = faster convection, which is why we blow on soup to cool it quicker.

Velocity near the surface of the turkey, near the fan

Airspeed near the turkey surface, opposite to the fan

Getting back to our contour plot, if we look at temperature, we can clearly see that inside the turkey the air is a lot colder. This is because it’s stagnant air. No hot air is making it’s way into the turkey. We can also see that below the turkey, in that 0.4 inch space our rack has provided us, the air temperature is also cooler then the rest of the oven. Again, because not a lot of fresh hot air is making it’s way in there.

Why is air having a hard time making it into the space between the turkey and the roaster bottom? Looking at the streamlines in the image below shows that essentially it’s the same reason that the air isn’t going into the turkey. The air coming out of the fan is going to follow the path of least resistance. To go under the turkey, it has to travel around the wall of the roaster, down between the turkey and roaster wall, then make a 90 degree turn to flow under the turkey. All the while, it’s slowing down, and cooling down. Both of those things are important, as cold air sinks, right? And since the air speed is lower then that of a natural convection current, hot fresh air is not going to displace this air. That is why it seems like the air makes it down into the roaster, but then can’t move further under the bird, and just recirculates by the roaster wall.

Pictures are great, but sometimes an engineer needs some numbers. Looking at the data, our oven fan is moving 22.8 CFM of air. The airflow rate going into and out of the roaster? 0.35 CFM, or 1.5% of the fan airflow rate. How much air is going into the cavities of the turkey? I tracked data for air entering/leaving the neck cavity, and the larger rear cavity. The airflow amounts were 0.08 CFM and 0.146 CFM, respectively.

What have we learned? Well, stuffing doesn’t impede airflow through the turkey because there is very little airflow to speak of. That isn’t to say that the added thermal mass of stuffing inside the turkey leads to longer cooking times and dryer turkey meat (a topic for a future blog). Don’t count on a lot of airflow under the turkey to make a full crispy skin bird. Maybe a taller rack would improve this, or a roaster with shallower walls, but I have my doubts. It seems to me, that a rack or carrots/celery/potatoes do the same thing, get the turkey out of the drippings. Any claim about allowing air to circulate all around the bird is false. Also it’s very important to rotate your turkey so it cooks evenly.

Hopefully this has got you thinking about thanksgiving, and airflow analysis, and likely pretty hungry. There are a lot of possible things to look at in the next month: Non-convection oven version, taller rack height/roaster wall height, different roaster materials, stuffing cooking time vs unstuffed. Oh, and what about smoking a turkey in a smoker bbq? Tune in for the next installment.

Next installment …

Grill Masters – Unveiling the secrets with CFD

Further reading

Modelling Microwave Oven Heating with Frequency Domain Simulation in Simcenter STAR-CCM+