SPDM with Teamcenter Simulation 2406 – 3 ways to win powerful digital thread prizes

Last month we hosted Realize LIVE in Las Vegas and Munich and heard inspirational presentations from companies including Navantia, Caterpillar, Honeywell, X-Energy and Northrop Grumman about how they use Teamcenter Simulation SPDM software to manage data and feed it into their enterprise-level digital thread initiatives.

A few weeks further on and we have just released Teamcenter Simulation 2406. In this blog I reflect on some key themes I saw in the customer presentations and dig into the latest release to see how those digital thread goals are furthered in version 2406.

1. SPDM enables traceability, consistency, clarity and accessibility

At Realize LIVE, Andy Sullivan and Richard Clark from Caterpillar gave us fascinating insight into their journey towards full use of simulation process and data management integrated with the enterprise PLM system, complete with the highs and lows of large-scale change management. Having been through this process, they addressed the value delivered by well-organized, accessible data when it comes to achieving clarity, consistency, and efficiency in simulation workflows. These advantages ultimately take them towards their goal – striving for the highest-quality engineering output.

Of course, none of the benefits highlighted above are achievable without the data being in the system to begin with. Storing simulation data in the SPDM database needs to become a matter of routine for all team members and that means the process has to be fast and convenient.

Desktop integration in Teamcenter Simulation 2406

With the recent release of Teamcenter Simulation 2406 we have delivered a new desktop application which provides one-click access for simulation engineers to upload models and result data to the Teamcenter database without needing to know their way around the enterprise SPDM/PLM system in detail.

This tailored application provides quick and uncluttered access to the things that matter most – the user’s inbox with incoming analysis requests and direct access to the relevant objects to retrieve input files and carry out the work. When completed, simply drag and drop files with live feedback on upload status and history. Teamcenter Simulation will safely store your files in a new or existing object, and following standard file upload rules.

2. SPDM with AI/ML is a game-changer

Once your data is managed, labelled, and connected, what next? Many companies are exploring the potential of AI algorithms for data searching and extrapolation with the ultimate goal of accelerating design cycles and fuelling innovation.

During Realize LIVE Las Vegas, Dr Tom Stoumbos, Northtrop Grumman’s Director of Engineering, shared some of his thoughts on the importance of data management in the context of AI on the Engineer Innovation podcast (you can listen to the full episode here). His challenge is to make sure that knowledge and insights produced by space vehicle engineering programmes are leveraged as much as possible, with the aim of maximising efficiency and consistency of analysis execution.

I believe we can save 50% of the time to market, meaning hardware being fully verified and validated and ready to launch, by engaging as soon as we can with AI and ML… so without a doubt, it’s a game-changer

Dr Tom Stoumbos, Northrop Grumman

Knowledge management in Teamcenter Simulation 2406

One of the many benefits of managing simulation data in an SPDM system is being able to retrieve, understand and reuse existing results instead of repeating work – saving time, cost and resources.

But how do you know when there is a suitable model already in existence that could fulfil your verification request?

The latest release of Teamcenter Simulation delivers a AI/ML powered simulation recommender that is seamlessly integrated with the verification and simulation request workflows. This automatically finds relevant historical simulations which match the same description as the one being requested, ranked in order of relevance.

3. SPDM and PLM enables digital thread continuity

Returning to Realize LIVE for a final piece of inspiration, a common thread throughout the customer presentations was a growing awareness of where it is possible to go using a comprehensive solution where SPDM is fully integrated in the enterprise PLM environment. We heard about process automation, design exploration, model-based product development, concurrent engineering and model-based systems engineering, to name just a few objectives.

Using Teamcenter Simulation SPDM, built on Teamcenter PLM, lets you connect simulation and test data back upstream to requirements and downstream to manufacturing so you can reach fully validated, optimal designs much more quickly.

Making this work in practice requires more than just the right data model, object relationships and organization. It also needs well-designed analysis workflows which bring the right pieces of data to the right places, combined with robust tool integrations which can seamlessly perform the heavy lifting.

Simcenter Amesim integration in Teamcenter Simulation 2406

Using the latest release you can achieve greater digital thread continuity with simulation and verification workflows when launching a systems simulation with Simcenter Amesim.

Using Teamcenter parameter management with Teamcenter Simulation lets you connect simulation request parameters with Simcenter Amesim parameters when launching a simulation – streamlining the workflow and eliminating errors.

Matlab and Simulink integration in Teamcenter Simulation 2406

While Teamcenter Simulation has always been an open ecosystem, fully customizable to work with any simulation or test tool (including 3rd party and customer in-house tools), it comes pre-configured with many popular tool integrations to enable seamless MBD and MBSE toolchains.

Teamcenter Simulation 2406 brings an upgraded integration with Matlab and Simulink which not only supports storage of Simulink models and Matlab scripts inside Teamcenter objects, but also delivers digital thread continuity by capturing Simulink input and output parameters. This allows you to execute Simulink tools as part of the verification management process.

CAE status updates in Teamcenter Simulation 2406

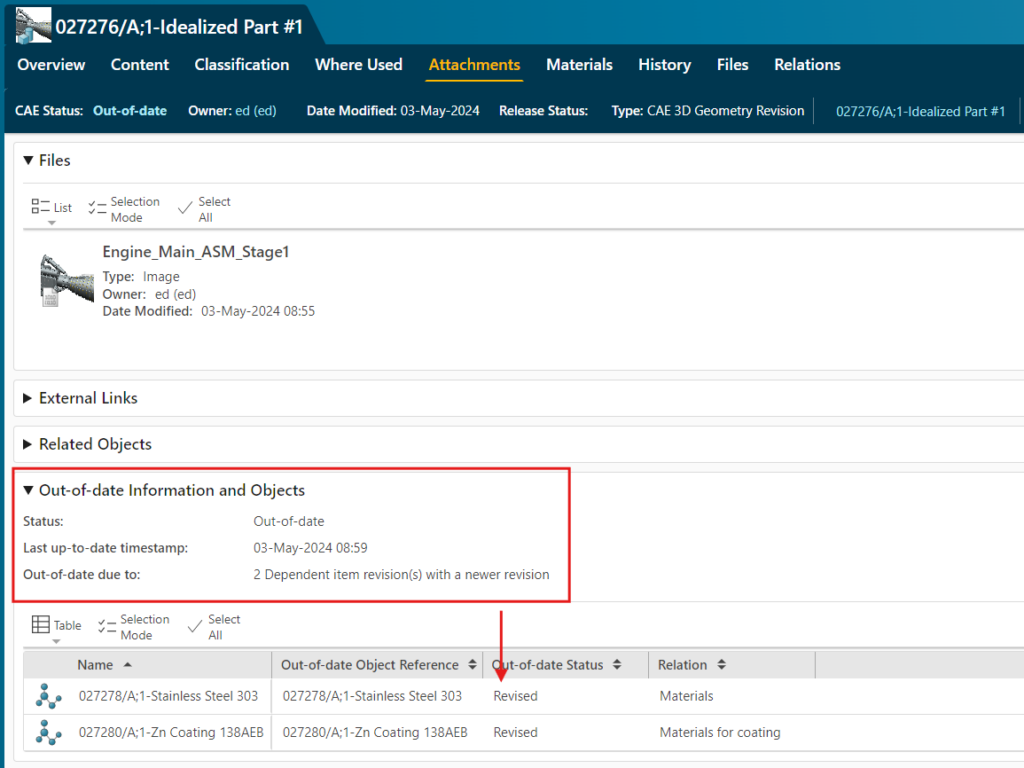

With more complex product BOMs and a move towards concurrent engineering in pursuit of shorter time-to-market, it is essential to know at a glance whether or not simulation or test data is in sync with the latest product definition.

The “Status” of a CAE object in Teamcenter Simulation indicates this synchronization (or lack of it) by checking the status of related objects in the database. In Teamcenter Simulation 2406, the CAE status now alerts you to changes in material properties and parameter values in addition to other revisions which impact your CAE analysis.

Let’s push the boundaries of SPDM and PLM even further this year

As always, the new capabilities highlighted in this blog are just the headlines. Check out the full release notes for more information on what’s new in Teamcenter Simulation 2406.

It just remains to say a big “thank you” to all of the customers who shared their stories with us as Realize LIVE this year. It is a privilege for us to learn about the state-of-the-art from you and to keep delivering new capabilities to help you push that further. I can’t wait to hear what the next 12 months bring!

To learn more about fully integrated SPDM and PLM with Teamcenter Simulation, visit our website.