Robotics engineering challenges no one talks about — Built for Engineers

Believe it or not, the robotics industry is taking the manufacturing economy by storm. All statistics indicate that our co-workers, drivers, and personal assistants will soon be sophisticated robots!

Do you know annually 500000 manufacturing jobs are going unfilled, weekly 70,000 baby boomers are retiring from the workforce and millennials, the future generation, are not so excited to join the manufacturing trade? Consequently, it is no wonder automation technologies, including robotics are growing at a breakneck speed.

With the arrival of technologies — 5G, edge computing, machine learning, artificial intelligence and advancement in vision technologies, the robotics industry is at the sweet spot to deliver on Industry 4.0 promises. But, creating robots that are autonomous, flexible to handle small batches of work at very high precision without compromising on safety is challenging.

Both established OEMs and start-up companies face the same robotics engineering challenges: balancing the intricate trade-offs between performance, reliability, accuracy, safety, and energy efficiency.

A robot isn’t just a mechanical arm. It isn’t a car either. While both are dynamic machines, a robot is a deeply integrated system where every decision creates a ripple effect across other domains. A change in the motor (low-frequency electromagnetics) impacts the arm’s vibration (mechanical), which generates excess heat (fluid & thermal) and forces changes to the control algorithm (automation).

Solving these problems in isolated silos with a “build it and test” approach is a recipe for failure. This traditional method, relying on costly physical prototypes, inevitably leads to late-stage discoveries that can derail projects, inflate budgets, and grind development to a halt.

There is an ingenious way. Using a couple of industrial robots as an example, let’s explore how a multi-physics simulation approach helps you master these interconnected challenges before you ever build a prototype.

1. Taming Dynamics: From Vibration to Precision

For a high-speed robot, precision isn’t lost—it’s stolen by uncontrolled dynamics. This is where insights from Simcenter become essential. To bring vibration back under control, you must first understand the complex forces and accelerations acting on not just the main robot arms, but also the joints, motors, and gearboxes.

Using Simcenter, you can simulate the robot’s complete operational cycle to:

- Precisely calculate the dynamic loads and accelerations on every part of the robot.

- Analyze how flexible components, like the arms and gearboxes, will bend and vibrate under those loads.

- Predict and neutralize the resonant frequencies that kill performance and cause long-term mechanical fatigue.

- Optimize the structural design for maximum stiffness and minimum weight using a topology optimization tool or an automated parametric design space exploration technique, throughout the different phases of the design cycle.

2. Right-Sizing Actuators for Peak Performance and Efficiency

The traditional “trial-and-error” or single-point calculation for actuator sizing is notoriously inefficient. It often leads to two bad outcomes:

- Under-sizing: The robot fails to meet performance targets.

- Over-sizing: A common “safe” choice that increases cost, weight, and, most importantly, energy consumption and heat.

Instead of guessing, Simcenter allows you to simulate the robot’s complete mission profile. By providing the motion paths as input, it precisely calculates the required speed, torque, and power. This enables you to select the optimal actuator from a catalog—one that is perfectly matched to the task, minimizing both cost and energy waste.

3. Ensuring Thermal Reliability and Safety

Actuator inefficiency creates another critical problem: heat. For robots operating 24/7, this constant thermal stress degrades components, increases failure rates, and creates significant fire hazards.

With the help of Simcenter, you can develop power demand management strategies and algorithms to limit the rise in temperature by controlling the robot’s operation.

- Identify and resolve potential hot spots in motors, gearboxes, and electronics long before prototyping.

- Virtually validate the effectiveness of cooling strategies, from optimizing heat sink geometry to improving component placement.

- Develop smart control logic that actively prevents catastrophic overheating by managing power and performance in real-time

and thermal analysis

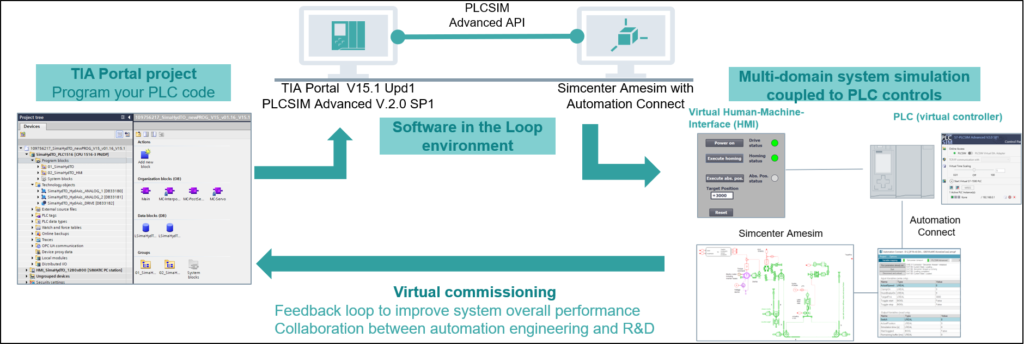

4. Accelerating Smart Controls with Virtual Commissioning

Automation and control engineers waiting for a physical prototype to validate PLC and HMI logic is a high-stakes waiting game. Bugs discovered at this stage are the most expensive and time-consuming to fix. Virtual commissioning with Simcenter completely de-risks this phase. By connecting your control logic (SiL/HiL) to the digital twin, you can:

- Validate every line of code in a risk-free virtual environment.

- Accurately predict machine cycle times and optimize acceleration/deceleration profiles.

- Commission the robot virtually, drastically reducing the time required on the shop floor.

5. Maximizing Autonomy and Minimizing Cost

In a factory with hundreds of robots, even small inefficiencies multiply into significant operational costs and the energy consumption profile might depends on the tasks. But true efficiency goes beyond just the motor. The motion profile itself—how the robot accelerates, moves, and decelerates—is a massive factor in energy consumption. Using a digital twin, you can run dozens of virtual tests

- analyze the trade-offs between operational parameters and their impact on energy use

- avoid inefficient stop-start movements and optimize robot path

- identify energy-efficient speed for a given payload

6. Model Accuracy and Troubleshooting

Robotics engineers now leverage powerful multi-physics simulations to predict everything from vibration to thermal loads. Yet, the ultimate test of a model’s accuracy still comes from the factory floor—correlating simulation data with measurements from physical prototypes to ensure the digital twin truly reflects reality.

- Correlate simulation results with test data to continuously improve digital twin accuracy

- Rapidly identify and diagnose unexpected robot behaviors through targeted physical measurements

Ready to Conquer Robotics Engineering Complexity?

The challenges in robotics engineering are deeply interconnected. Therefore, the solution cannot be siloed. By embracing a holistic, multi-physics simulation and testing approach, you can move from a slow, expensive cycle of “build, test, fail, repeat” to a dynamic process of virtual design, validation, and optimization.

To see these principles in action, watch the webinar on robotics engineering.

One last thing. As explained, the era of siloed robotics engineering is over. The future belongs to teams that embrace a holistic, integrated approach. The companies that master this integrated simulation and testing workflow won’t just build better robots—they will define the next generation of automation.

Download the whitepaper “Take Control of the Robot Complexity and Cost” to learn more.

Comments

Leave a Reply

You must be logged in to post a comment.

I was sick of playing on clunky mobile sites that take forever to load. A mate told me about the rooli casino app downloadand I gave it a shot. The installation took maybe two minutes and the difference is night and day. Everything runs smooth on my phone, no lag or crashes like other platforms I’ve tried. For Canadian players, the Interac integration makes deposits instant and withdrawals just as quick. I’ve been playing a few rounds after work and the whole experience just feels polished. Worth the tiny effort to download if you’re serious about mobile gaming.