Robotic systems – exploit the physical limits

Robots are everywhere!

Machine Learning and A.I. move more and more into the mainstream of engineering. Scalable electronic control systems of today can handle a multitude of sensors and input data to perform ever more complex tasks. Therefore trends like collaborative robots and fully autonomous systems are becoming the norm – from shop floors to nursing homes. In this blog, I’d like to put emphasis on the engineering toolchain. How can we push those systems to their physical limits, while ensuring durability and safety? Simulation of robotic systems helps bringing them to their physical limits. Especially, let’s look at automation of production and industrial processes, where time is money. Let’s take the example of this pick and place operation:

Multi Body Simulation

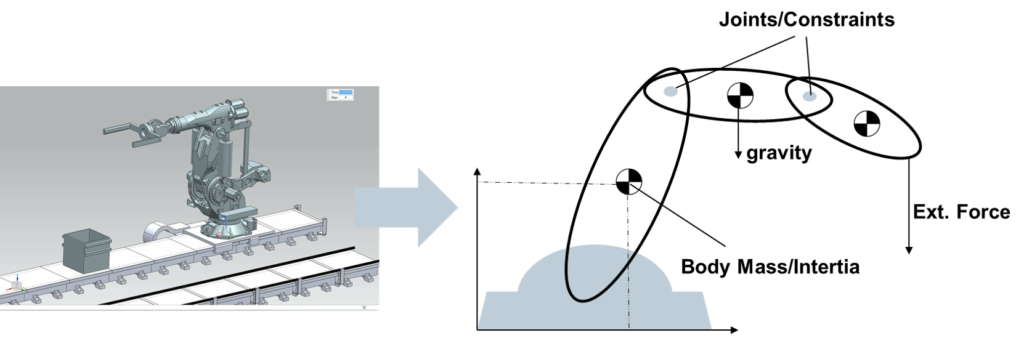

Kinematics are the first thing to assess, e.g. avoiding collision with other objects. But in addition, what defines the forces acting on the structural components? How can those can be designed and sized accordingly? One way to look at this is Multi Body Dynamics. The animation above shows the result of a simulation. Each component of the machine is represented by its mass and inertia. The model takes into account gravity, external forces (like the weight of the box) and the kinematic degrees of freedom.

While this is a big step forward, we can increase fidelity further in order to get full information. The forces on the components increase, when we perform the movement faster.

How fast can this movement actually be performed in the simulation? I am glad you asked. 😉

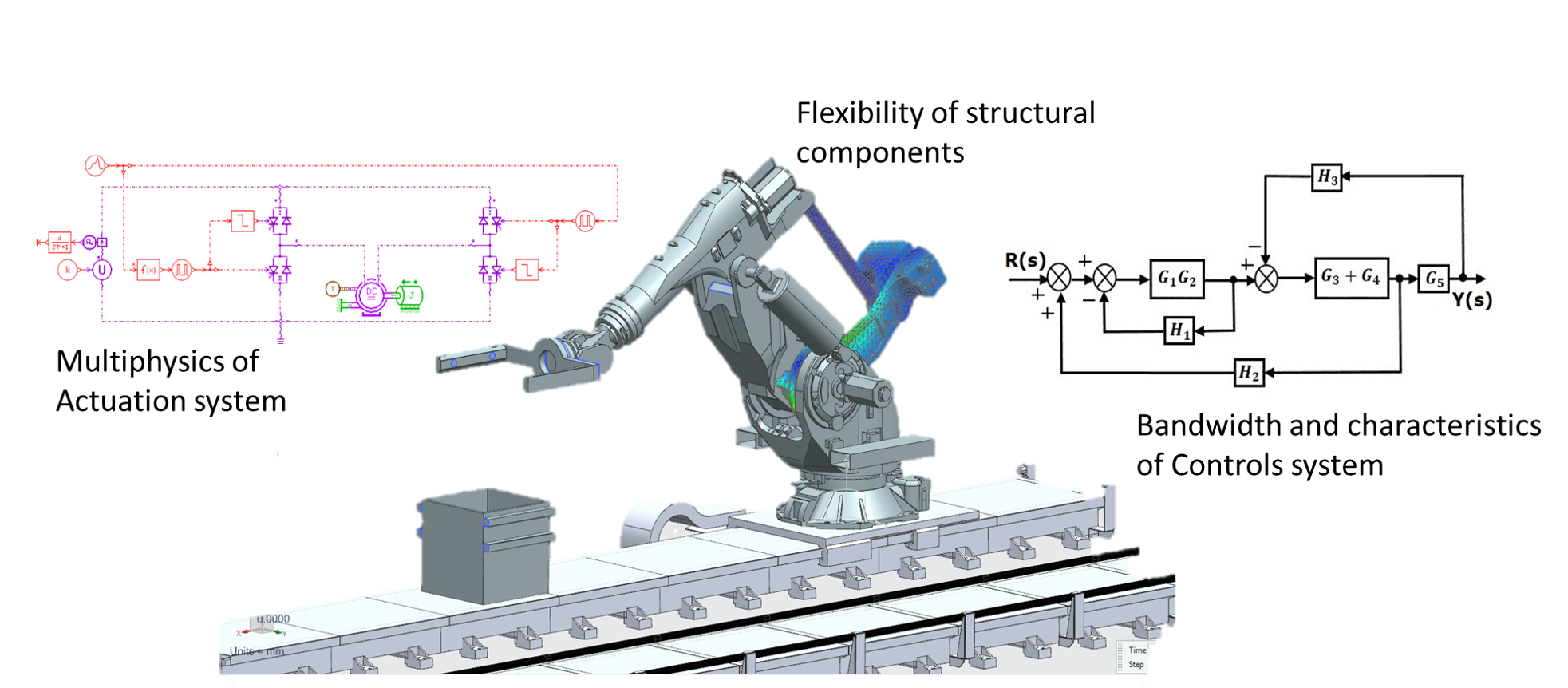

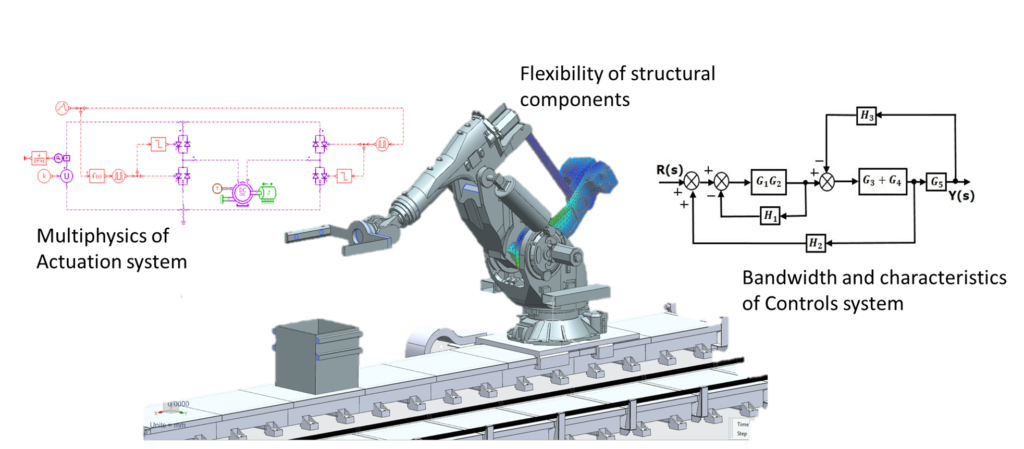

Actually, the bandwidth of the actuators and the control logic of the robot define this limit. With co-simulation, the MBD model “cooperates” with a controlled Multiphysics model of the actuation. At simulation run-time two (or more) solvers exchange information. For example: The MDB solver gives positions and accelerations to the controller/actuation, while the Multi-Physics solver responds with corresponding forces.

Lastly, performing the operation faster leads to more dynamic or abrupt movements. Components will start to deform or vibrate. These effects can be considered in the MDB model as well.

Such a simulation model gives valuable insights into the loads and operational conditions at every location of every component of the robot in order to optimize the structure and ensure durability. Take the example of controller failure below:

Related use cases

The same principals apply for many systems, e.g. the dynamics of controlled + actuated flight simulator plattforms. In the following video E2M, a Siemens customer, sheds light on how they use Simcenter 3D and other Siemens tools for various analyses of their plattforms, e.g. the assessment of movement under actuator constraints to prevent collisions or the stress analyses of components.

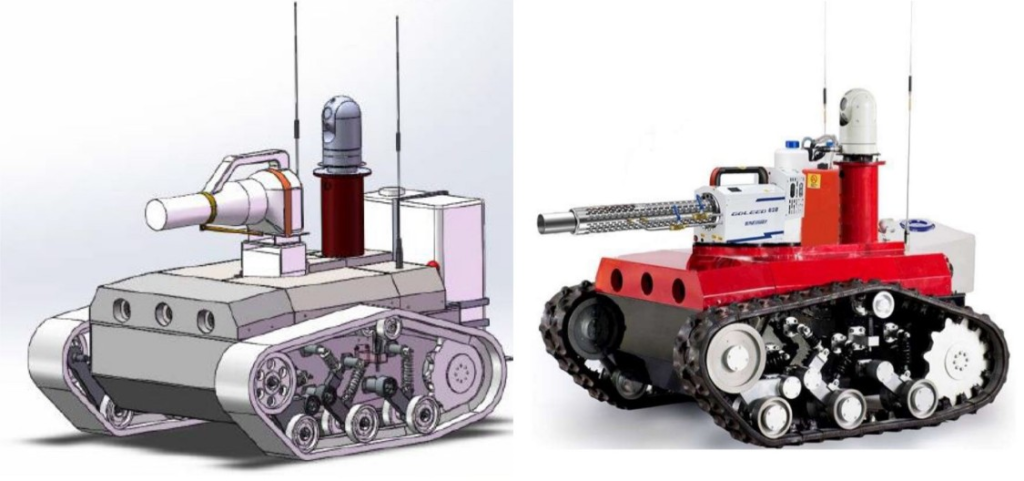

So far so good – for stationary systems in a defined environments. A previous blog covered, how Aucma built an Intelligent disinfection robots made with NX help fight the virus. It is crucial to reflect on the tasks a robot is designed for.

Creating virtual models representing real operational conditions helps to do just that. So while the disinfection robot operates on level building floors, other robot drones might encounter different terrains, like a rescue drone:

Conclusion

Whatever your robot might be up to: Simulation models of the dynamic system help to ensure safe and lasting operation, taking into account all relevant aspects. There are of course more challenges to robotics engineering, take energy efficiency or actuator sizing. It is the combination of simulation and engineering disciplines, which in their sum constitutes to a Holistic Digital Twin. See my colleague’s blog for more on System Simulation for Robotics: https://blogs.sw.siemens.com/simcenter/robotics-engineering/

Join our free robotics webinar on Oct. 29th. Many additional aspects will be discussed: https://www.plm.automation.siemens.com/global/en/webinar/robotics-engineering/88189

There is one last thing. Do you know why your caged robots tremble and how to overcome it? You can read the following blog, which highlights vibration troubleshooting and characterizing unwanted resonance.