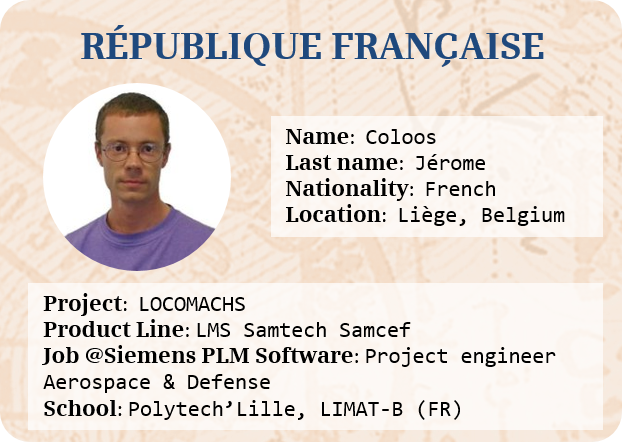

Researcher of the Month – Jérome Coloos

What you probably don’t know is that we’re involved in a variety of international research programs around the globe – everything from safer, quieter and more efficient airplanes to electronic vehicle research. It is something we’ve been doing for years and it is a great way to incubate new concepts and ideas that later transform into market-ready products. It is an amazing place for young researchers and grad students to really push their limits in a business environment.

Where did you study?

Where did you study?

I studied at the Polytech Lille in France, where I earned my degree in mechanical engineering. I then started a PhD. at the Laboratoire d’Ingénierie des Matériaux de Bretagne (LIMAT-B) in Lorient, France, where I’ve been involved in developing finite element software as well as in studying mechanical deformation effects on fiber optic cables.

How did you end up at Siemens?

How did you end up at Siemens?

I arrived at Samtech in 2000. It was 6 months before the end of my PhD. I worked with the optimization team, focusing essentially on topology, genetic algorithms and neural networks. Today, I am still working in the Liege office, and now, Samtech is a part of Siemens.

What is your project about?

What is your project about?

The project I’m working on is called LOCOMACHS, and is quite ambitious. The main objective is to significantly reduce the most time-consuming (non-added value) operations in composite and hybrid structure manufacturing and assembly.

I’m part of a team whose goal is to reduce by 50% the recurring costs of shimming. We are including variation management and geometrical tolerances into part flexibility to achieve the best possible fit between parts and avoid or minimize shimming.

Together with Airbus Group Innovation and ENS Cachan (Paris area), we worked on a CATIA V5 simulation workbench to implement the AnaToleFlex (ANAlyse de TOLErance FLEXible) solution. We evaluated the assembly process performance, taking into account geometrical deviations for each part and their detailed mechanical properties.

Why did you choose this area?

Why did you choose this area?

This project required knowledge about CATIA V5 architecture and programming and the LMS Samtech Samcef solver. At that time, I hardly had heard about geometrical tolerance, but I was the perfect fit for the team.

Learn more about LMS Samcef Solver Suite.

What is the craziest thing you have ever done as an engineer?

What is the craziest thing you have ever done as an engineer?

There’s a particularly challenging task that comes to mind. I’d been asked to write a programming tool to recreate the geometric topology of a plane skin, with only simple input like a list of vertices, edges, and surface patches contained in an ASCII file. I remember struggling and needing to refresh some old knowledge about NURBs, and having to apply it on a large scale

What is the best thing about your research project?

What is the best thing about your research project?

As an engineer, it is when you work on a project and know that the tools you’re developing will be actively used by the industry in the future. Often, at the beginning of a research project like this, your goals seem so far from your starting point that you can’t do anything but hope that you’ll be able to reach them.

When you realize at the end of the project that you did actually bring some unique value to the product, it’s a great relief. If the tools we’re currently developing are used somehow in the future, and help the system integrator, then it will be the best thing about the project.

What is the worst thing?

What is the worst thing?

That we are working on a platform of a competitor and not directly in our own platform. Of course, it wasn’t an issue when we started the project since LMS Samcef Samtech wasn’t a part of Siemens, but it became more complex a few months later, when the acquisition was announced.

Do you think your work will really make a difference?

Do you think your work will really make a difference?

The main challenge is to combine two major existing software solutions: the first is ANATOLE, dedicated to rigid tolerance analysis, and the second one is the LMS Samtech Samcef mechanical solver from Siemens PLM Software. To do this within the right type of interface, I think it would definitely make an impact in the industry.

25 years from now, there will be:

25 years from now, there will be:

I guess in 25 years, it will be time for me to retire! (laughs)

What would you do differently, if you could?

What would you do differently, if you could?

I keep as a motto to never regret any decision you take. But to be honest, I do regret the decision to go skiing the black trail in the Alps when I was 17, which was indeed completely iced. My right knee never fully recovered from the crash I got into on that day.

If you weren’t an engineer, what would you be?

If you weren’t an engineer, what would you be?

When I was younger, I’ve always wanted to dive with Commandant Cousteau’s expeditions. I could also picture myself in Indiana Jones adventures. I’d say that I always looked forward a mix of knowledge and adventure.

Will engineering change the world?

Will engineering change the world?

As a whole, science and knowledge do change the world. And as an engineer, you have a strong role to play in this change!