Power Cycling and Thermal Testing Engineering Services

Increasing need for Power Cycling and Thermal Testing

The energy demands of both consumer and industrial electronic systems are increasing Power electronics component suppliers as well as OEMs are faced with the challenge of providing highly reliable systems needed for aviation, electric vehicles, trains, power generation and reusable energy production. The need for Power Cycling and Thermal Testing is paramount to maintain the safety and reliability of these systems.

Power components are used for applications in which electrical energy is generated, converted or controlled and where very high reliability is required over many years of constant operation. As the demand for these components grows, so does the demand for reliability and the need for thermal characterization. Semiconductor manufacturing, Automotive, Aerospace, Consumer Products, Military and Defense … no industry is immune.

Far too often, customer engineering demands require timely action, delivery schedules, system start-up and capital approval cycle can cause unacceptable development delays.

Siemens and M4 Engineering partner up to bring you Reliable Testing

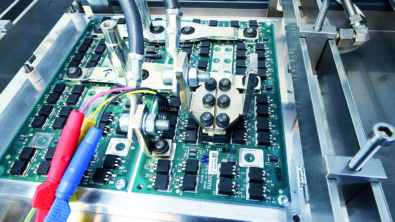

In close cooperation with Siemens Simcenter, channel partner M4 Engineering of Long Beach, CA, will start delivering power cycling and thermal testing as a service in September 2020. With the acquisition of a Simcenter PWT2400 Powertester, M4 will be capable of providing thermal transient characterization and/or active power cycling testing of high-power semiconductor components and modules. Services will be available for customers throughout the world.

Some of the key benefits would include:

- Create/verify thermal metrics, datasheet information following JEDEC Standards

- Discover thermal barriers and defects in your package and thermal system effectively

- Understand the how and why a component might fail

- Gather data for subsequent mission profile based lifetime estimation

- Test components from 10 Amps up to 2400A

- Test based calibration of thermal digital twins

Take a look at these case studies to see how Yamaha and Toyota have benefitted from Power Cycling and Thermal Testing.

How M4 can bring Power Cycling and Thermal Testing to You

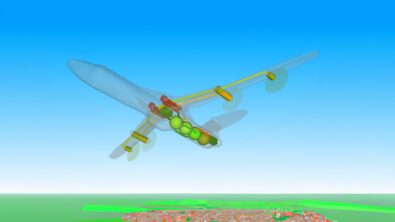

Founded in 2001, M4 engineering provides services and software including conceptual, detailed and industrial design, analysis and simulation with an emphasis on structures, aerodynamics, flight performance, dynamics, electronics and loads and vibration. M4 has special experience and software for key technical areas such as weight prediction, rotor dynamics and vehicle optimization, as well as general design and analysis services and software.

As a Siemens channel partner, M4 will also resell and support the Simcenter POWERTESTER, Simcenter T3STER, Simcenter TERALED, Simcenter DYNTIM, Simcenter Flotherm and FLOEFD products.

For more details or a cost estimate please contact Andras Vass-Varnai or Al Prosuk of Siemens Simcenter.

To learn more about the importance of power cycling and thermal testing, I found this recent web seminar on Simulating and Testing the Latest Technology for EV Power Electronics explained the processes really well. Take a look for yourself and watch the recording here.

If you’re interested in finding out more, here is a great white paper on “Automotive power electronics – accurately predict field reliability“, which you can read now.