Optimizing turbine maintenance schedules at Hydro-Québec

Power outages often have negative effects on people’s day-to-day lives. Prolonged times without energy can, for instance, defrost foods stored in freezers, reset your appliances’ settings, disable wi-fi connections, and unable you to recharge your electronics. A power outage can also be critical for surgeries or medical procedures performed in smaller clinics without back-up generators.

That is why energy producers strive to provide continuous energy with the most minimal downtime possible. However, it is sometimes necessary to check up on the status of the machinery used for power generation, and to fix or replace parts that break. In order to not only tend to but predict maintenance needs, power distributors are now investing in test data measurement equipment and software to manage their turbine maintenance schedules in the most efficient way possible.

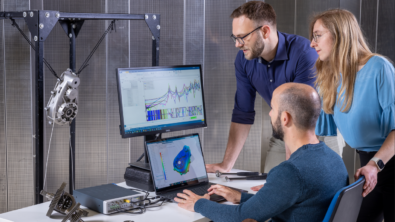

Courtesy of Hydro-Québec

Courtesy of Hydro-Québec

Hydro-Québec, North America’s largest producer of renewable energy and operator of an extensive high-voltage transmission system, uses Simcenter Testlab and Simcenter SCADAS to maximize their testing efficiency onsite. They rely on the versatile equipment our portfolio offers, implementing an innovative multidisciplinary technology approach seamlessly. Test data is widely used to validate assumptions on the complex models. This helps them monitor vibration levels and better predict optimal turbine maintenance intervals.

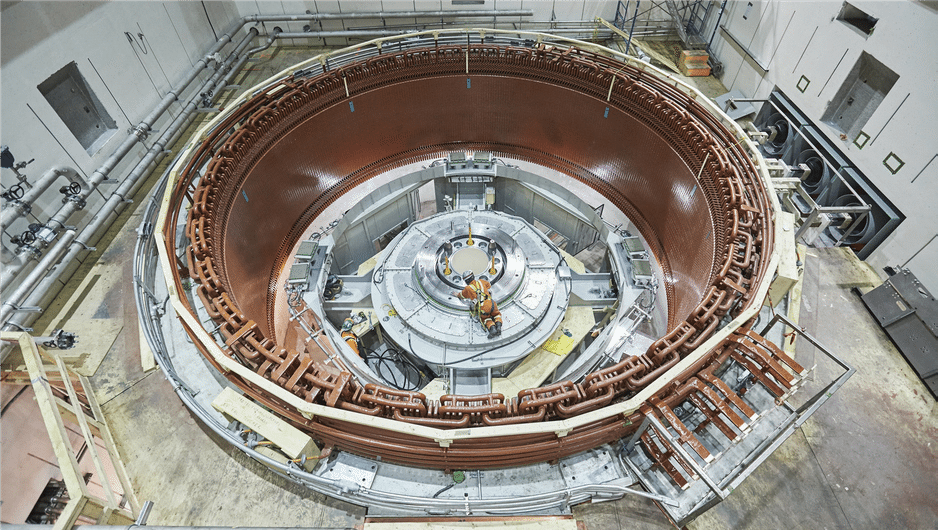

Courtesy of Hydro-Québec

Courtesy of Hydro-Québec

Hydro-Québec also relies on its research institute, the Quebec Electricity Research Institute (IREQ) to optimize the maintenance of the large turbines used in hydroelectric power generation. Since some measurements cannot be performed when the turbines are in use, the timing of tests depends on the grid needs. For example, no tests are performed during the winter, when people use the most power, but in the spring or in the summer. During these seasons, multidisciplinary IREQ researchers visit Hydro-Québec to perform extensive tests on idle turbines, using our solutions. The objective of the tests is to evaluate turbine conditions to be able to predict maintenance needs well ahead of time, and to implement innovative methods that reduce maintenance time and intervals. The goal is that the turbines operate permanently, keeping the shutdown episodes that occur for research, maintenance or repair purposes to a minimum, ensuring continued energy delivery and full customer satisfaction.

Read more about how Hydro-Québec uses the Simcenter solution to optimize their maintenance plan in the case study