Lost luggage? Carry your portable vibration testing equipment

Agfa Graphics solves the issues of delayed shipments, complex custom clearance procedures, and more using a portable vibration testing solution.

Do you also hate it when you finally arrive at your destination after a long flight (in a too-tight economy seat), and you stand there waiting and waiting for your luggage? … and it does not show up!

These types of situations can be frustrating. It might even take a few days before your suitcase shows up. So, in the meantime, you can hopefully buy a fresh shirt and a toothbrush in the local store.

But what if you just traveled as a test engineer to the other end of the world for an important measurement campaign? What if your testing equipment is not on the belt? This is not something you can easily buy at the next-door shop. You might risk sitting in your hotel room for a day or two, waiting for the equipment to arrive. This is costing you time money and may jeopardize the entire whole measurement campaign.

The solution? Portable vibration testing equipment!

With exactly this scenario in the back of their mind, Agfa Graphics was excited to see our Simcenter SCADAS XS when we first presented it to them a few years ago.

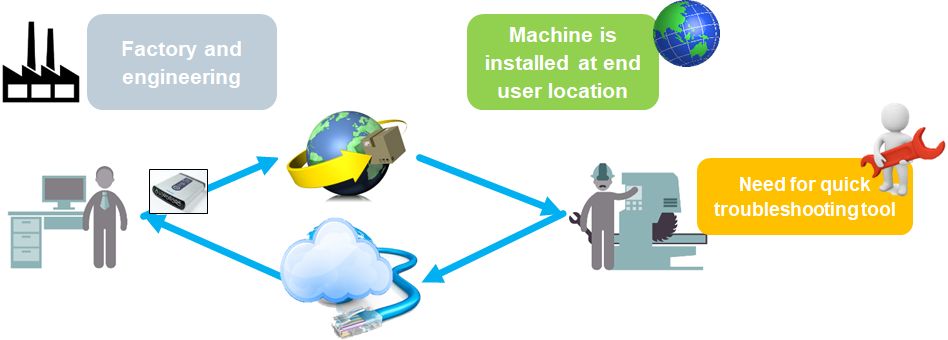

Serving one-fourth of the printing industry with prepress technology, Agfa Graphics supports their worldwide installed base, detecting and troubleshooting vibrations of printing plates in the production lines of their end customers. In the past, they used bulky measurement systems that needed to be checked in as luggage, which often caused delays due to lost luggage or difficulties getting it through customs. In addition, they had to send an engineer along with the equipment to do the actual tests, which blocked the engineer’s availability typically for a full week per measurement campaign.

Simplify the shipment procedure

Indeed, using the SCADAS XS, Agfa engineers can now preconfigure the system in their office with specific measurement tasks. It is small enough to be shipped with standard parcel services to the other end of the world. It is also simple enough to use so that a local operator can perform the test.

As all data is securely saved on the embedded memory card. Either the SCADAS XS or the data files return to the engineer based at headquarters, who can then analyze the vibration issue in detail without having to travel.

This new working procedure reduces the typical involvement of the engineer from a full week down to only 1-2 days. Imagine the return on investment – you can do the math!

Are you curious about how Agfa Graphics uses the Simcenter SCADAS XS? Read the full story here.

Want to learn learn more about the Simcenter SCADAS XS? Visit the Simcenter SCADAS XS page on the community.