Intelligent Design Exploration and CFD- engineering better than nature

This year we have all become much more aware of the role of evolution in nature. In fact, we are locked in race against a virus which appears to be evolving rapidly before our eyes. The headlines are filled with daily warnings of new variants of the Coronavirus. And meanwhile the world battles to keep infections under control.

But if you take a closer look, in fact, the mechanism by which nature produces variants of the virus is rather simple. The virus sets each cell which becomes host to work making copies of the proteins required to create new viral particles. The virus enters the cell with a single copy of its genome. Within a few days, the cell will be full with several hundred to a thousand new copies of the virus.

But due to errors in the RNA/DNA replication, few to none of these new viruses are likely to contain an exact copy of the viral genome. On average there is an an error in every 10,000 – 100,000 bases. The entire Coronavirus genome is ~30,000 bases long. Given the number of infections recorded, nature must have already introduced to upwards of 100 million billion different versions of the virus to the world (give or take a few million billion). This is maybe not the smartest way – it’s even based on random errors – but it is design exploration on a huge scale!

Can we copy nature? Shall we copy nature?

So, nature is developing new prototypes and testing them out. Much as we do on a smaller scale with our own engineering projects. Back in the 1960s, researchers were hopeful that mimicking this natural selection could be the key to automating industrial design processes. With a typical engineering problem having far fewer free parameters than a viral genome, it seemed plausible.

But there is a problem. Inherent to the biological process of evolution is a reliance on being able to generate a vast number of genetically diverse offspring from which the most fit will pass on their genes. But human engineers don’t have the time or resources to investigate anywhere near the number of designs that nature is testing! That’s why design exploration is not enough. Intelligent design exploration is what we need.

Enter: Intelligent Design Exploration

Thankfully, research into optimization and search algorithms has continued undeterred over the past 70-odd years. Technology available today goes far beyond what is possible using genetic theory. With a plethora of highly sophisticated optimization approaches in use engineers have a powerful set of tools in their hand– yet each with their own strengths and weaknesses.

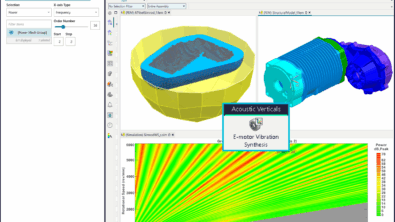

Intelligent Design Exploration in Simcenter STAR-CCM+ makes optimization a realistic technology for engineers by simultaneously employing multiple search strategies (including genetic algorithms) while exploring designs. It intelligently blends between the different strategies. By this means it ensures that it tackles each design space using the most efficient method available. Simcenter STAR-CCM+ does all of this behind the scenes, leaving the engineer free for, well, more engineering.

It is now routine to solve complex design problems in weeks and even days that were completely infeasible before. I’d like to share with you a couple of recent examples which demonstrate how far this technology has evolved.

The importance of keeping your car clean

Over the last decade we have seen an explosion in the number and type of sensors in our cars. Ensuring correct and continuous function of these sensors in all weather conditions and driving environments is critically important. Especially with the emergence of autonomous vehicles.

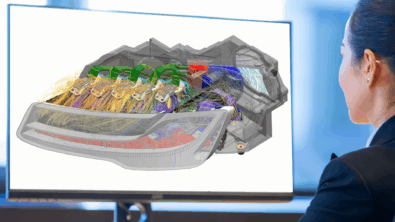

Volvo Cars and Siemens recently undertook a study to see how Intelligent Design Exploration could help to mitigate soiling of a camera lens mounted beneath a car sideview mirror. The engineers simulated water accumulation and motion on the side view mirror using a fluid film model in conjunction with steady state aerodynamics CFD. They defined 11 different design parameters controlling different parts of the car’s bodywork. Based on that they explored the design space with the objective of reducing the average fluid film thickness accumulated on the camera lens.

Reducing aircraft fuel consumption

We all know that an aircraft must have guaranteed performance over the full envelope of flight conditions. The most beautifully optimized design at one angle of attack might perform terribly at another. This means that designers must look at performance across many different operating conditions for each design candidate.

My second example shows how aerospace engineers used Intelligent Design Exploration. Here they use the technology to refine the design of an engine nacelle on the Eclipse business jet. See this webinar for more information. In this case the aircraft had over 20 operating conditions for which performance had to be guaranteed. A detailed analysis of these allowed us to reduce the list down to 5 cases representing the most extreme conditions.

Eight different design parameters control the nacelle surface, orientation and mounting on the fuselage. The engineers analyzed each nacelle design at 5 operating conditions. The objectives were to minimize drag and maximize engine inlet pressure recovery for all operating conditions. At the same time meeting performance requirements for the inlet flow uniformity.

The results of this study were stunning. After fewer than 60 design iterations, we were able to improve all 15 objectives with an improvement of 14% reduction in drag at cruise, the most critical objective in the problem. This was achieved while satisfying the flow uniformity requirements for all 5 operating conditions.

The future is bright – bright as Intelligent Design exploration

Over the past few years, Intelligent Design Exploration has become more and more mainstream. Today, it is no longer the reserve of the ‘special projects team’ or the ‘algorithm guy’. The two examples we have explored in this blog show two things. Firstly, that a combination of simulation and Intelligent Design Exploration can have a huge impact on product performance. Secondly, it can massively accelerate the development process, ultimately giving design teams the opportunity to develop more innovative products.

I’m reassured by this evidence that science, technology and intelligence can find solutions more quickly than nature will. And I hope you are too. By making decisions based on measured data, testing those decisions and refining based on real-world performance, we stand an excellent chance in the face of the very real challenges that humanity will continue to encounter!