Structural dynamics breakthrough: 10 powerful Siemens contributions driving a better future at IMAC 2026

Join Siemens at the 44th International Modal Analysis Conference (IMAC), where innovation meets real-world impact!

The IMAC conference at the Riviera Resort & Spa in Palm Springs, CA is the world’s leading event for structural dynamics professionals, bringing together researchers and industry experts to explore the latest advances in testing, simulation, and digital transformation. This year, our Simcenter Physical Testing team from Siemens Digital Industries Software is proud to present a record number of cutting-edge contributions, underscoring our commitment to pushing the boundaries of engineering. Mark January 19–22, 2026 in your calendar and don’t miss it!

Why attend Siemens sessions at IMAC?

- Discover innovations first: Get an exclusive look at pioneering methods in structural dynamics, multi-axis vibration testing, AI-driven modal analysis, real-time digital twins, and more.

- Meet the experts: Engage with Siemens engineers and researchers who are shaping tomorrow’s solutions.

- Real-world impact: See how our technologies are solving today’s toughest challenges in aerospace, automotive, energy, and beyond.

Pushing the boundaries of structural testing: Siemens innovations in MIMO testing, automation, and digital twins

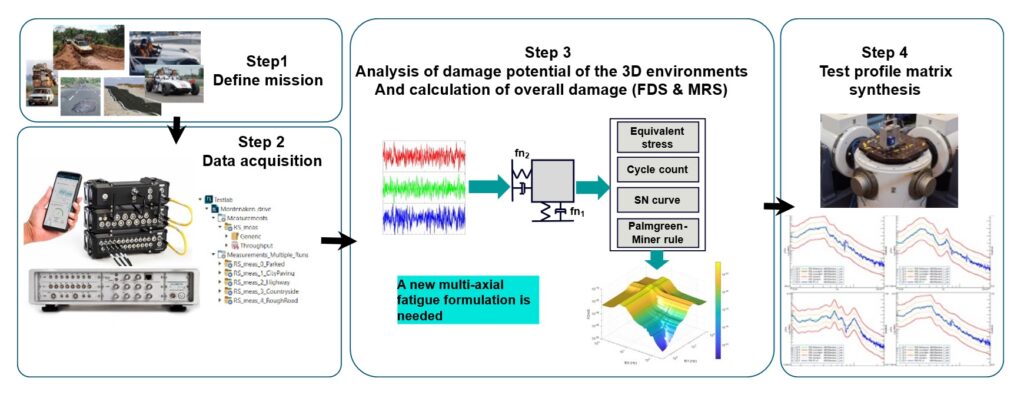

Multi-DOF durability approach for tailored multi- and uniaxial vibration Tests

Main author: Alberto García de Miguel

Time: Tuesday, January 20, 9:00 AM (local time)

Paper no.: 20366

“Our new multi-DOF durability framework enables more realistic vibration tests, unlocking the full potential of advanced shaker platforms.”

— Alberto García de Miguel

Abstract:

Modern engineering faces unprecedented challenges in vibration testing as structures become increasingly complex. Traditional uniaxial testing often fails to replicate real-world damage mechanisms. This presentation introduces a novel multiaxial fatigue damage formulation, extending standard fatigue analysis to multi-axis tests. By incorporating cross-correlations and a multi-DOF severity metric, the approach enables more accurate mission synthesis and test tailoring, ensuring that multi-axis platforms are fully leveraged for durability validation.

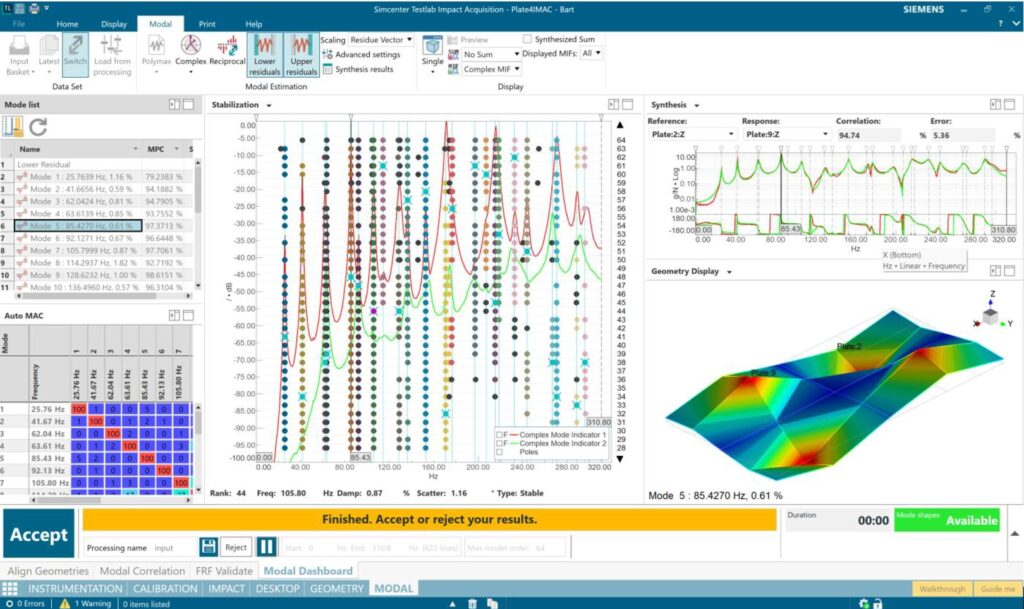

Guided analysis tools for highly efficient impact testing and modal parameter estimation

Speaker: Bart Peeters

Time: Tuesday, January 20, 10:00 AM (local time)

Paper no.: 20537

“Smart Hit Selection and AI bring expert-level modal analysis to every engineer automatically.”

— Bart Peeters

Abstract:

Impact testing is a cornerstone of experimental structural dynamics, but efficiency and quality are often limited by manual processes. This session highlights the Smart Hit Selection (SHS) method, which automates optimal impact selection for Frequency Response Function (FRF) measurements. Additionally, a Hybrid AI approach combines machine learning and rule-based expertise to automate modal parameter estimation, delivering results with expert-level accuracy and minimal human intervention.

Virtual shaker testing using a real-time executable digital twin

Speaker: Mattia Dal Borgo

Time: Tuesday, January 20, 10:00 AM (local time)

Paper no.: 20664

“Real-time digital twins let us predict and optimize vibration tests before they happen.”

— Mattia Dal Borgo

Abstract:

Dynamic testing of spacecraft and components is vital to assess their integrity under operational loads. This presentation introduces a virtual shaker testing approach, where a real-time digital twin of the test setup is connected to the vibration controller. This allows engineers to safely test an emulation of the entire system and predict the outcome of the physical test before its execution, improving setup, control parameters, and without the risk of damaging the device under test and the shaker.

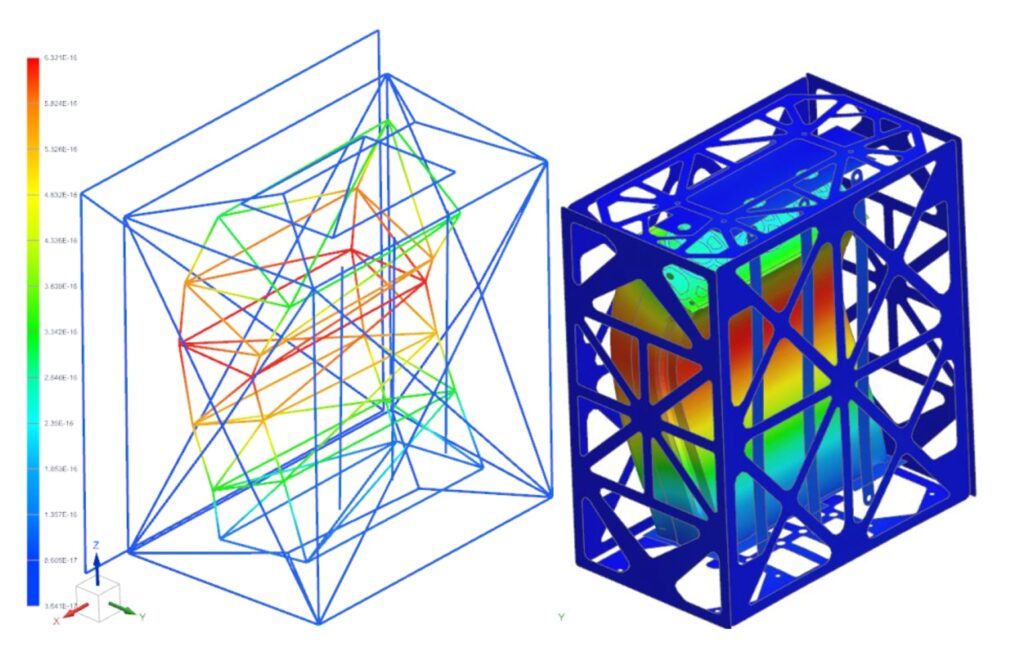

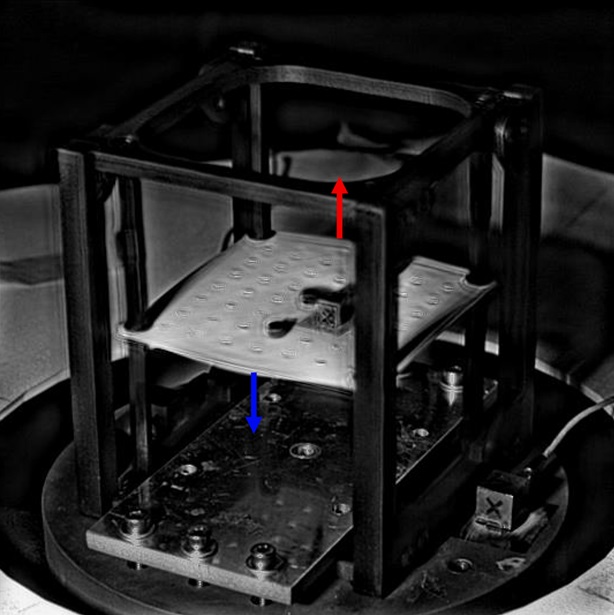

Shaker testing of a fuel cell stack: Modal survey, FE model updating, and fixture coupling neutralization

Speaker: Giancarlo Kosova

Time: Tuesday, January 20, 5:00 PM (local time)

Paper no.: 20637

“Shaker testing is essential for validating fuel cell stack durability and refining our numerical models.”

— Giancarlo Kosova

Abstract:

This study presents a comprehensive approach to fuel cell stack testing, combining experimental modal analysis, finite element model updating, and fixture decoupling. The results demonstrate the importance of accurate testing and model correlation for predicting structural integrity and optimizing design in real-world operational conditions.

Next-generation structural insights: AI, video-based analysis, and multiphysics sensing by Siemens

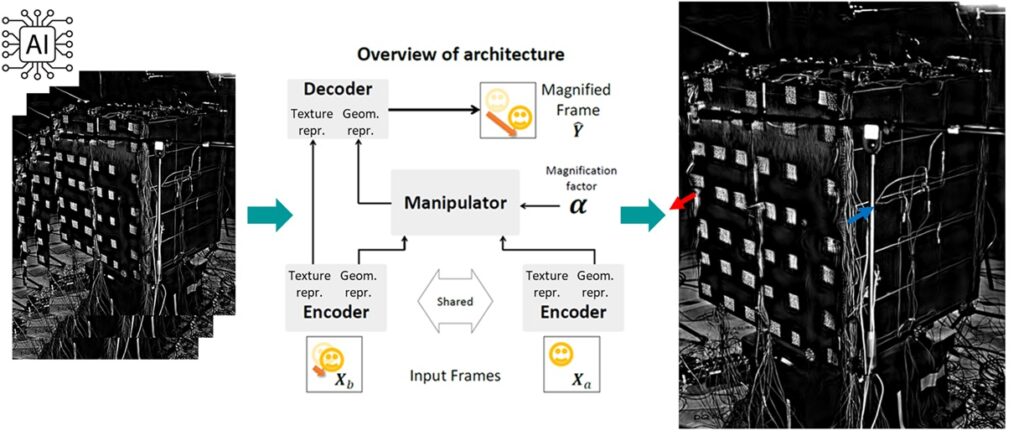

Full-field operational deflection shapes magnification using a convolutional neural network

Speaker: Prof. Francesco Cosco (University of Calabria, co-author with our Siemens colleagues)

Time: Wednesday, January 21, 9:40 AM (local time)

Paper no.: 20327

“Deep learning enables high-fidelity, full-field deflection shape visualization from simple video.”

— Francesco Cosco

Abstract:

This work introduces a novel convolutional neural network (CNN) approach for extracting and magnifying Operational Deflection Shapes (ODS) from high-speed video. The method delivers clean, high-quality ODS animations enabling non-contact, full-field observation of structural dynamics.

Structural response characterization under multi-axis excitation via video motion magnification

Main author: Davide Mastrodicasa

Time: Wednesday, January 21, 10:20 AM (local time)

Paper no.: 20438

“Video motion magnification lets us identify critical responses before real testing—non-intrusively.”

— Davide Mastrodicasa

Abstract:

This presentation explores the use of Video Motion Magnification (VMM) for pre-test analysis in vibration control tests. The goal is to visualize the full-field structural dynamics in a rapid manner to identify the most critical responses, helping test engineers to de-risk the test campaign. By integrating synthetic image generation in Blender, the feasibility of camera-based displacement retrieval can be validated before physical testing, helping to optimize test setups.

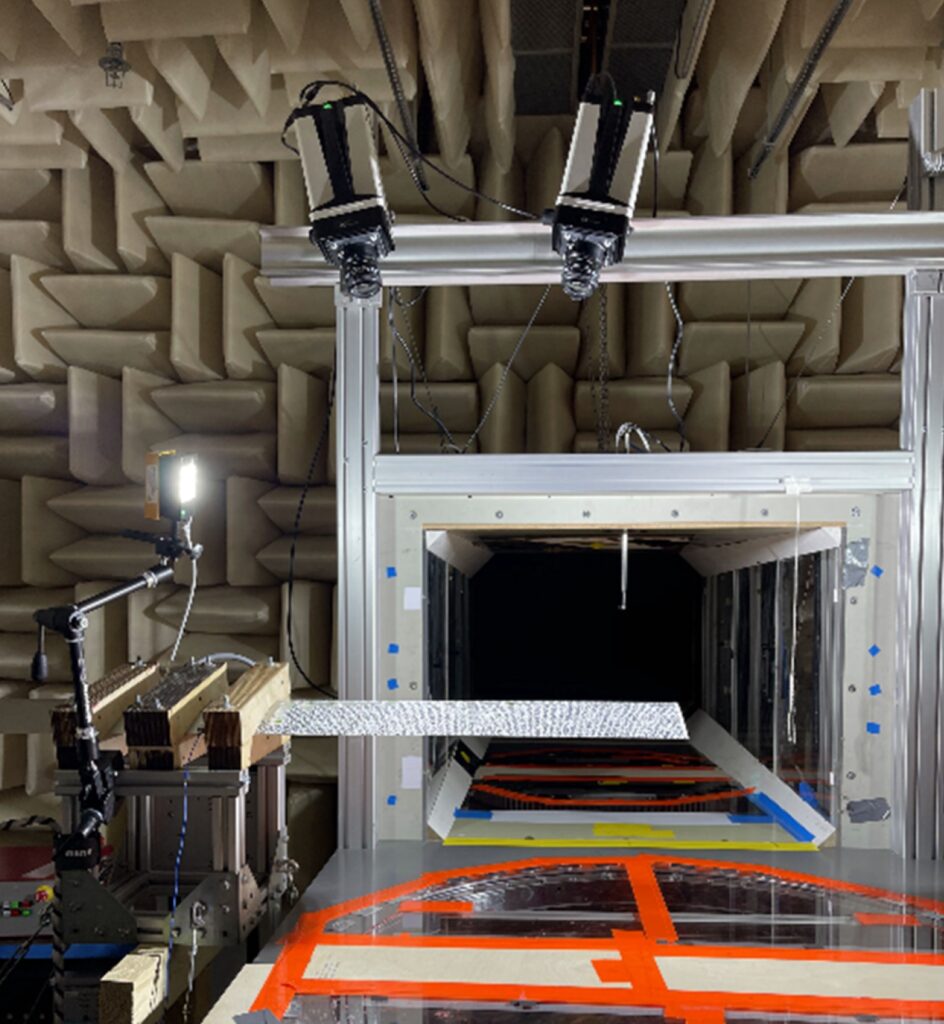

Multiphysics modeling for virtual sensing of an aluminum wing in wind tunnel tests

Speaker: Silvia Vettori

Time: Wednesday, January 21, 11:40 AM (local time)

Paper no.: 20480

“Our Kalman-based virtual sensing framework estimates full-field responses with minimal sensors.”

— Silvia Vettori

Abstract:

Understanding fluid-structure interaction is vital for modern lightweight structures. This session presents a Kalman-based virtual sensing framework that uses a multiphysics approach to estimate full-field strain, displacement, and pressure fields from limited sensor data, reducing the need for extensive instrumentation.

Smart monitoring and NVH excellence: Siemens advances in automated damage detection and E-Mobility

Automated data-driven damage detection in structural health monitoring of wind turbine blades

Speaker: Silvia Vettori

Time: Thursday, January 22, 10:20 AM (local time)

Paper no.: 20422

“Automated, data-driven SHM enables early damage detection and smarter maintenance.”

— Silvia Vettori

Abstract:

This work validates and automates a signal processing algorithm for detecting damage in wind turbine blades. Developed by the Mechanical and Aerospace Engineering Department at University of Rome “Sapienza”, the approach combines Principal Component Analysis (PCA) and Independent Component Analysis (ICA), to support efficient, real-time monitoring and early damage detection. The entire process has been integrated within an automated monitoring workflow using Simcenter Testlab Workflow Automation (TWA), enabling automatic calculation and tracking of the damage indicator across multiple measurement sessions.

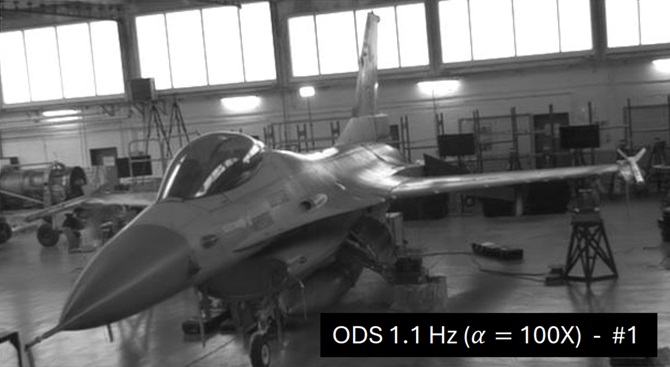

Camera-based operational modal analysis and modal magnification: A full-field approach using phase information

Speaker: Prof. Francesco Cosco (University of Calabria, co-author with our Siemens colleagues)

Time: Thursday, January 22, 11:10 AM (local time)

Paper no.: 20474

“Full-field OMA is now possible with just a single video camera and advanced phase-based processing.”

— Francesco Cosco

Abstract:

This presentation demonstrates a phase-based video motion magnification technique for full-field Operational Modal Analysis (OMA). The approach enables extraction of modal parameters and mode shapes using only a single camera, validated on both laboratory and full-scale aircraft tests.

Battery pack integration: experimental and modal modeling for NVH performance

Main author: Fabio Bianciardi

Time: Thursday, January 22, 2:30 PM (local time)

Paper no.: 20458

“Frequency-based substructuring helps us predict and optimize EV NVH performance early in development.”

— Fabio Bianciardi

Abstract:

Integrating battery packs into electric vehicles poses unique NVH (Noise, Vibration, Harshness) challenges. This session discusses experimental Frequency-Based Substructuring (FBS) for predicting and optimizing NVH performance. Modal modeling is hereby considered for increasing data consistency. A novel modal model identification approach is proposed, and its targeted use in battery-to-body integration is evaluated.

What sets Siemens apart at IMAC?

- Pioneering research: Our team leads the way in MIMO testing, AI-powered analysis, and (real-time) digital twin technology.

- Industry collaboration: Siemens presentations are grounded in real-world projects, from spacecraft to wind turbines and electric vehicles.

- Accessible expertise: Whether you’re a seasoned engineer or new to structural dynamics, our sessions are designed to inspire and inform.

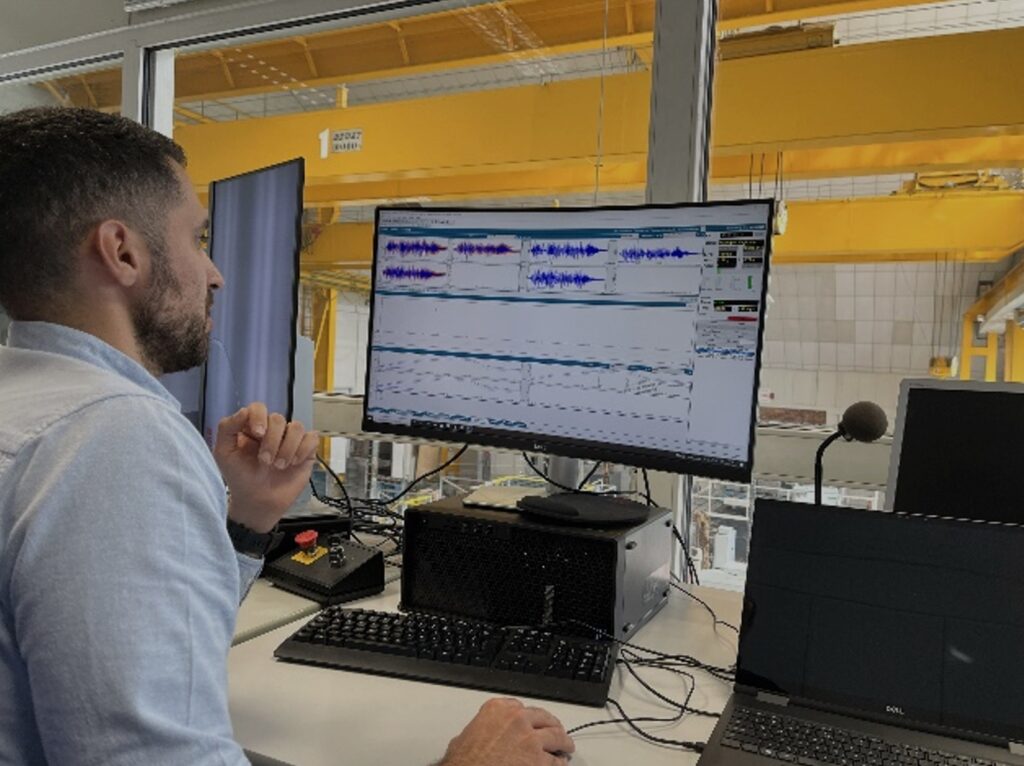

Visit the Siemens booth for structural dynamics insights

Stop by the Siemens booth to explore how Simcenter SCADAS and Simcenter Testlab empower structural dynamics testing. Learn directly from our experts about advanced workflows for impact testing, high-channel data acquisition, automated modal analysis, and digital-twin-driven vibration studies. Get practical insights you can apply immediately to improve test efficiency, accuracy, and confidence your front-row seat to the future of structural dynamics.

Join Us at IMAC 2026!

Don’t miss the chance to connect with Siemens experts, discover the latest in structural dynamics, and see how innovation is turning challenges into opportunities.

Explore the full IMAC program

For a deeper dive into Siemens’ IMAC contributions, Register and follow us on LinkedIn for live updates.

Let’s shape the future of structural dynamics together at IMAC 2026!