How autonomous and eco cars drive virtual design, verification & validation

It’s fair to say that today’s cars are computers on wheels, as they transformed over time from pure mechanics to integrated systems combining mechanics and software. Modern vehicles are software-intensive mechatronic systems integrating over 100 Electronic Control Units (ECU) connected through various types of E/E networks. Today, 80% of the innovation in this segment is associated to electronics and software, and it is anticipated that this will only increase as autonomous driving will require some of the most complex software implementations that carmakers have ever faced.

These autonomous systems will need algorithms that integrate information from multiple sensors, traffic data from the cloud or data coming from other vehicles (V2V) or infrastructure (V2X) such as navigation or traffic, information detected from other cars on the road, etc. Responsibilities of the driver shift to the vehicle manufacturer stressing the importance of good virtual verification and validation processes as millions of test scenarios need to be covered.

In addition to that, the more stringent emission regulations will force OEMs and suppliers to apply innovative technologies to help them in cutting down emissions. Increased penetration towards electric vehicles (EV) and hybrid vehicles (HEV) is expected to increase the automotive electronics market drastically.

This drive for innovation results in more complex ‘mechatronic’ systems topologies. This increasing importance of embedded software within vehicle design has a strong impact on the productivity, quality, safety and costs. Design revisions are exploding, while market expectations impose always faster time-to-market. The growing number of software-related recalls and industry standards like the ISO26262 addressing issues related to safety of electrical and/or electronical systems in newly produced cars reflect an emerging battleground in the automotive industry. Almost every single system of the vehicle has been impacted by electronics and electronics, and today it represents more than 40% of a vehicle’s cost, up from 20% just 10 years ago.

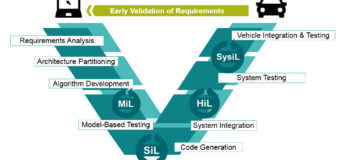

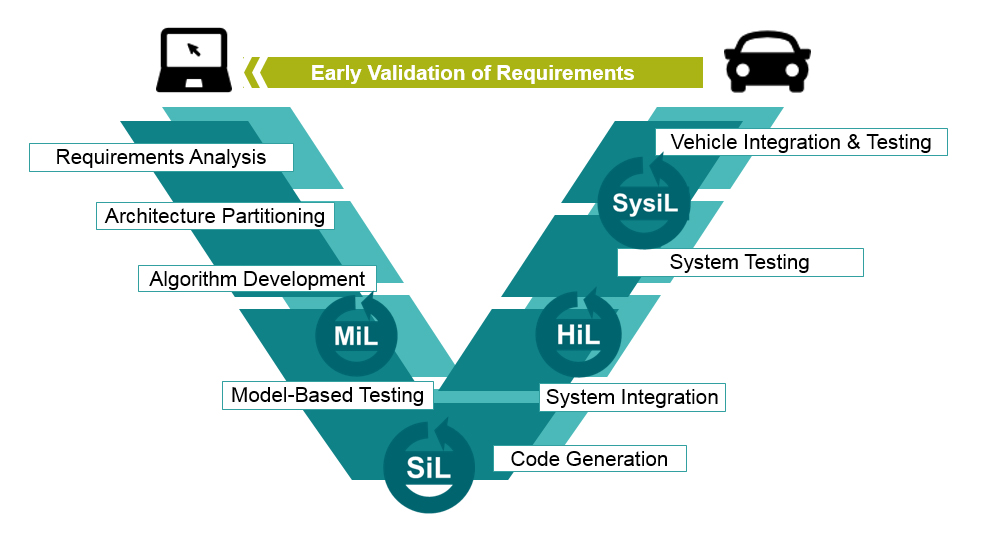

As an outcome, it has become critical to implement a virtual design, verification and validation process, integrating the control and mechanical disciplines continuously along the development cycle to support the development of autonomous green vehicles while keeping time and budget under control.

Watch our free webinar to better understand:

- How closed-loop design enables better architecture design and allows to detect earlier integration problems, before the first prototype testing

- How a concurrent approach helps controls and software engineering departments to develop and validate best-in-class mechatronic systems by bringing the “Digital Twin” engineering approach

- How companies like Renault, Mazda or Denso have successfully deployed solution to design high-quality and smart software and E/E networks in the least possible time.