Home appliances. From noise reduction to sound quality.

What is the first thing you do when entering the hotel room after a long and exhausting flight? Maybe you want to go straight to bed? Or finish that Powerpoint presentation for your meeting tomorrow?

Well … not me…

The first thing I do, is to check out the mini-bar! Not because I’m thirsty but rather to switch it off. During the night, when everything around is quiet, it disturbs me every time the fridge compressor switches on, even if the noise level produced is very low.

Next to the hotel room example, the trend of smaller living areas, open kitchens, increasingly dense cities with more apartments makes also customers more sensitive to the noise generated by home appliances. Imagine you just finished a nice meal at home with some friends. Who wants their after-dinner conversation to be disturbed by the dishwasher cleaning the dirty plates?

For all kind of home appliances, the noise level as well as how they sound becomes more and more important. Manufacturers of dishwashers, washing machines, laundry dryers, HVAC … realize this trend and can use sound as a brand identity and competitive advantage.

In order to bring to market quieter products, manufacturers of home appliances and white goods can optimize the noise levels as well as the quality of the sound produced.

Following the ISO-based sound power procedure allows comparing noise values between different equipment in an absolute way, independently of the distance to the object or the acoustical environment where it was measured. The value obtained from the ISO sound power test is also the one that appears on the European Energy Label for white goods. It allows manufacturers to compare their equipment with their previous generation or with competitor brands. And for the end user it guarantees they pick the quietest brand when going to the appliances store or shopping on the internet.

Measuring the sound power value is just one thing, but what if your main competitor just released a new model that is – guess what – 1 or 2 dB lower than yours? This might make you lose the market share and can cost you a lot of money.

How will you make sure that you can further decrease the sound power value of your next generation dishwasher or washing machine? Just using trial and error approach? Based on your past experiences of what worked and what didn’t? By randomly adding a lot of acoustical material? Needless to say, this trial and error approach is far from optimal and there is no guarantee for success.

Smart strategies to improve the noise of your home appliances

Luckily different test-based approaches can help you lowering the sound power value in a systematic and time efficient way.

As a strategy, you can BLOCK the noise, try to FIND where it comes from and with some further details, you can UNDERSTAND the underlying phenomena.

Product noise reduction strategies

Product noise reduction strategies

Block the noise

You can BLOCK the noise quite easily by adding acoustic material to dampen or absorb the noise before it enters the room. Typically, a bitumen layer is put on the side panels of e.g. washing machines or dishwashers, but also extra acoustic material inside the equipment can help lowering the final noise level.

But what if you want to try out new materials or a combination of multiple layers? You do not want to apply the different acoustic materials each time on a full dishwasher. Quantifying the acoustical absorption and transmission loss characteristics of such materials can be done on a small sample using impedance tube standards (so-called acoustic material testing). As an alternative, also room-based testing setups provide the same absorption and transmission loss curves.

Check out the case study from 3M.

Find the noise leak

Once you selected the optimal material, knowing where to apply it is the next key issue: you can put the acoustical material everywhere on all panels. A better approach is to FIND the locations where such material is most effective. If you produce thousands of dishwashers a day, saving 1 cent per unit on acoustical material means a huge cost saving. Knowing where most noise leaks out will tell you where you need to modify the design by e.g. adding acoustic material (and where not). The fastest way to find the noise leak is by using array-based sound source localization technique such as the Simcenter Sound Camera. Real-time holograms show the acoustical hotspots as well as the critical frequencies. Very similar to an infrared camera – where colors indicate the zones with higher temperatures, the sound camera shows where the highest noise levels are originating.

Understand the noise path

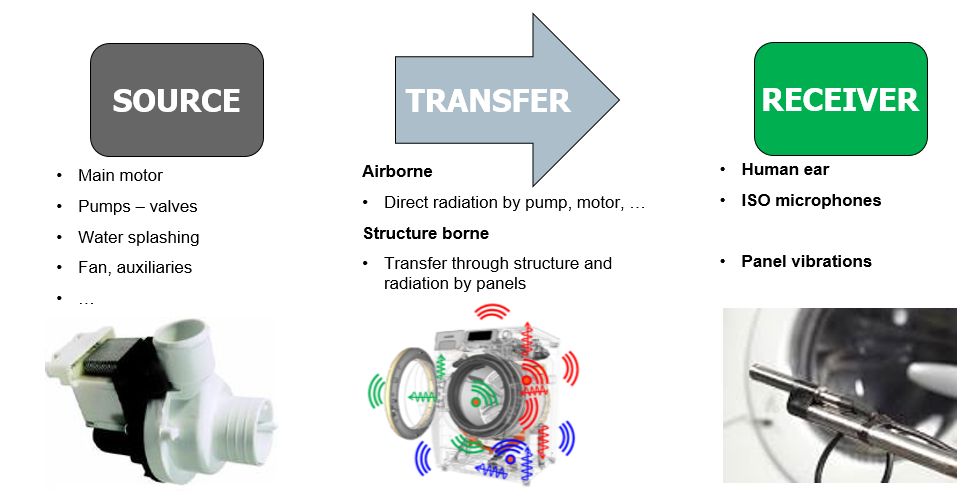

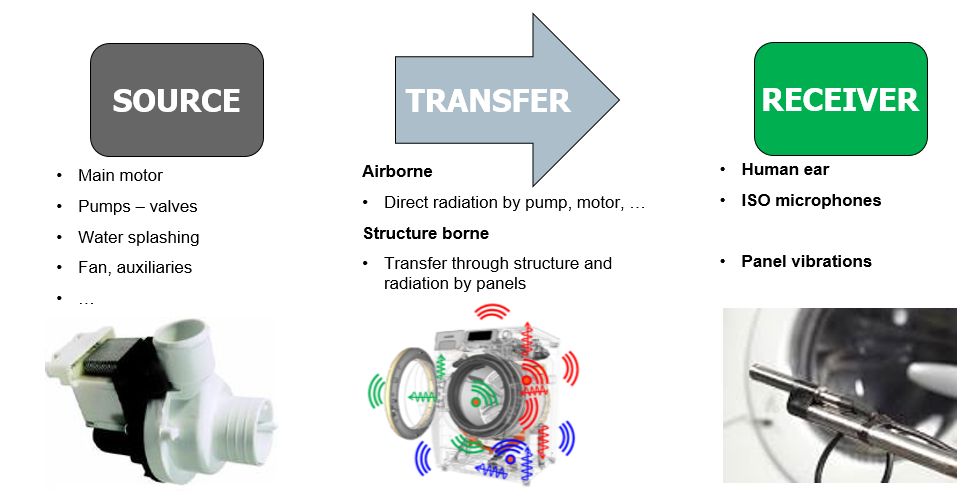

Instead of looking where noise is radiated into the environment, another strategy can be to tackle the problem from insight. A washing machine has a lot of moving parts – rotating motors and belts, springs that hold the tumble … which either generate vibrations and induce noise (the sources), or amplify certain frequencies (the transfer paths) such that an unexpected noise problem might occur (the receiver end).

Using our source transfer receiver approach helps you UNDERSTAND the underlying dynamic phenomena.

All components are identified and characterized in function of their dynamic behavior. Understanding their interaction and knowing the critical frequencies and paths help determine the “guilty component” you should work on. This systematic approach can start very simple – using impact testing and looking at transfer functions. Or it can get as detailed as building a complete dynamic model of your washing machine using transfer path analysis (TPA).

Interested in a show case? Here one from Little Swan.

Shape the noise

Some manufacturers of home appliances even go one step further: once they have the noise levels well under control, they start to examine how their equipment sounds and if this is appreciated by end customers. The beeping sound when pushing the start button, the opening and closing of the door, the splashing sound when the washing machine cleans the clothes… SHAPING the generated sound so that human beings like it, is the domain of sound quality engineering. While it might be rather new to the home appliances industry, it is well-established expertise in the automotive industry for years.

First of all, recording of different sounds is done using a binaural recording device like the Simcenter SCADAS XS with the binaural headset.

These high-quality recordings can either be used to calculate sound quality metrics or to run some listening sessions with a sample group of customers, called jury testing.

Sound quality metrics are objective calculations that intent to express how well certain sounds are appreciated by human beings. While jury testing does the same in a subjective way by replaying the recorded sounds to a group of people and asking their judgement.

As jury testing sessions are very time consuming, the ultimate goal is to find that “golden formula” which is a combination of sound metrics that correlate well to the results obtained from a jury testing campaign.

For all aspects of this sound quality process – binaural recording, sound metrics and jury testing – the Simcenter Testlab software and Simcenter SCADAS platform offer dedicated tools and specific user interfaces that help complete those tasks in the most efficient and user-friendly way.

All in all, combining different testing techniques will guarantee that you get the noise levels as well as the sound quality of your home appliances under control. Use the systematic approach to avoid any guessing or trials and errors.

So, who knows … next time I enter my hotel room I might not have to pull that power plug anymore!

Want to know more about the different techniques discussed? Feel free to follow a free educational webinar on acoustic material testing or download the white paper on noise control methods.

Comments

Comments are closed.

Fantastic that you worry so much about the noise that your machines make, but then add mind-numbing beeping to virtually every appliance that I am unfortunate enough to have as part of my furnished flat. The microwave, the diswasher, the dryer, washing machine, stove – whatever it is, when it is done doing something it will beep. Over. And over. Again.