Exploring the future of heavy equipment electrification with Simcenter Amesim

We usually consider the heavy equipment industry as conservative from an innovation standpoint. That may be because of its B2B (business conducted between companies) nature and consequently OEMS deliver product that are used as tools.

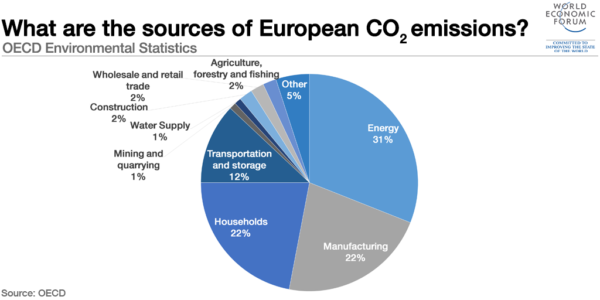

Additionally, CO2 emissions reduction requirements coming from regulators are not yet enforced as in the automotive market. This is due to the relatively low impact of heavy equipment machines on global warming (See figure 1). However, many signals tend to say that CO2 emissions reduction will be required in the off-highway sector soon. This new regulation will come on top of other drivers like noise pollution reduction, low emission zones or StageV pollutant emissions limits for machines below 19 kW.

Simcenter Amesim as an electrification enabler

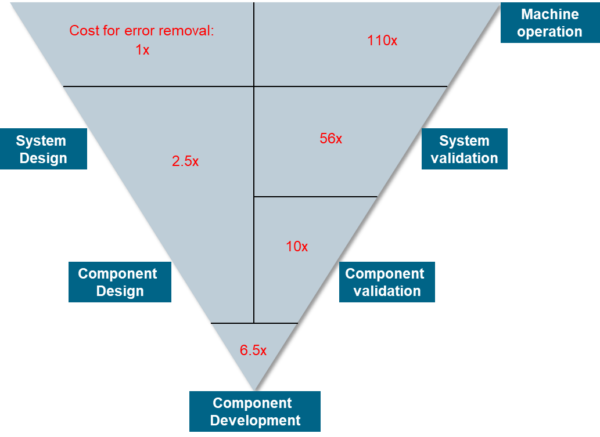

In this context, electrification is a relevant engineering solution to consider for some of the heavy equipment machines. It is time for manufacturers to explore electrification by initiating research project, establishing relationship with new suppliers and building an “electrification know-how”. Building this know-how using a traditional engineering approach (prototype based) would take years and significant cost to meet market expectations.

Instead, relying on Simcenter Amesim is a way for manufacturers to explore electrification possibilities and to prepare the future products. This is what Mecalac did with the e12, a battery electric wheeled excavator: Construction machinery manufacturer uses Simcenter Amesim to develop electric wheeled excavator. You’re eager to learn more about our solutions? You can register to the on-demand webinar about hybrid excavator and battery electric tractor simulations.

For more information please visit our webpage dedicated to electrification in the heavy industry, or read that blog post on how to “Reassure your end-users on their electric-powered heavy equipment investment thanks to simulation and testing”