Green hydrogen production simulation within Simcenter Amesim

A strong rise of the interest in green hydrogen production

The demand for today and the future is for true zero-emission power. Alternatives must be found to replace fossil fuels. Currently, batteries are a solution for automotive. Unfortunately, they are not suitable for many applications due to limitations with storage capacity, lifetime, charge constraints and environmental concerns. Therefore, green hydrogen production (produced for instance by electrolysis, using renewable electricity) is identified as a promising solution for long-term zero-emission renewable energy storage.

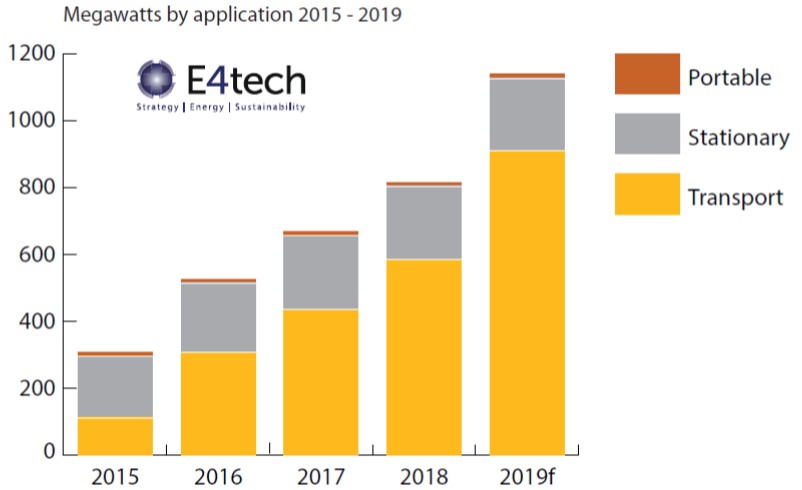

In 2019, the power generated thanks to hydrogen had the order of magnitude of the power delivered by a modern nuclear plant. And for a few years, hydrogen consumption rose rapidly. This trend will continue to grow significantly as many countries have recently committed large investments to increase hydrogen production and usage for transportation, energy or the industry.

Fig. 1: Evolution of hydrogen consumption

Most hydrogen is still produced from fossil fuels, which means that new infrastructures must be developed with the following challenges:

- Green hydrogen production, without any CO2 emissions. Water electrolysis is one solution, using clean electricity generated for instance from wind turbines, solar panels, wave converters or a combination of these.

- The improvement of the system performances, reliability and efficiency in order to reach an acceptable price for the produced hydrogen

- The storage of the hydrogen. As this gas has a poor mass energy density in ambient conditions, it is usually compressed or liquefied for storage.

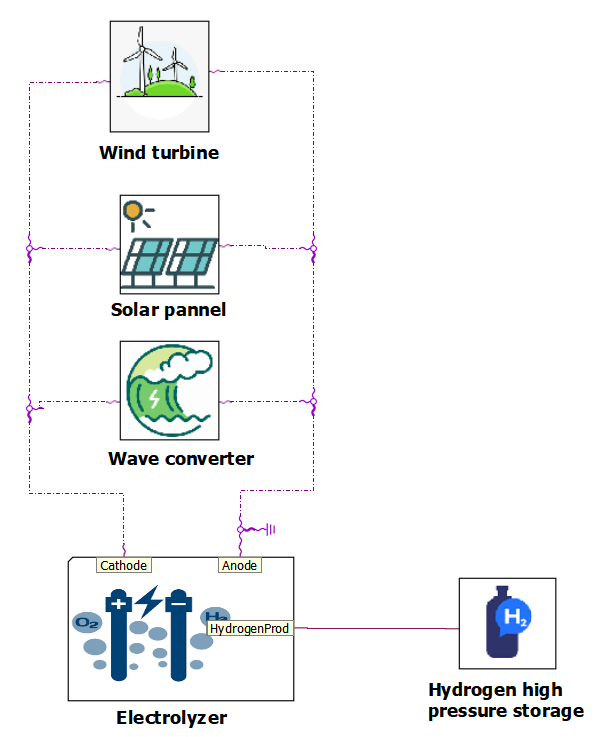

Fig. 2: Hydrogen production plant

So, how do we address these challenges, capture the behavior of a hydrogen production plant and each of its subsystem?

A model combining all subsystems to evaluate global performances

Green hydrogen production simulation within Simcenter Amesim is the solution. It makes it possible to capture the complete process of green hydrogen production, predict interactions between subsystems and the global performances.

Fig. 3: Hydrogen production plant model in Simcenter Amesim

We will consider now the example of electric power generated from 3 different green sources:

- Wind turbines

- Solar panels

- Wave converters

The electric power is used to power an electrolyzer generating hydrogen. The hydrogen is finally compressed in order to store it in high pressure tanks, ready to be used, refuel vehicles or to be transported.

Wind turbines

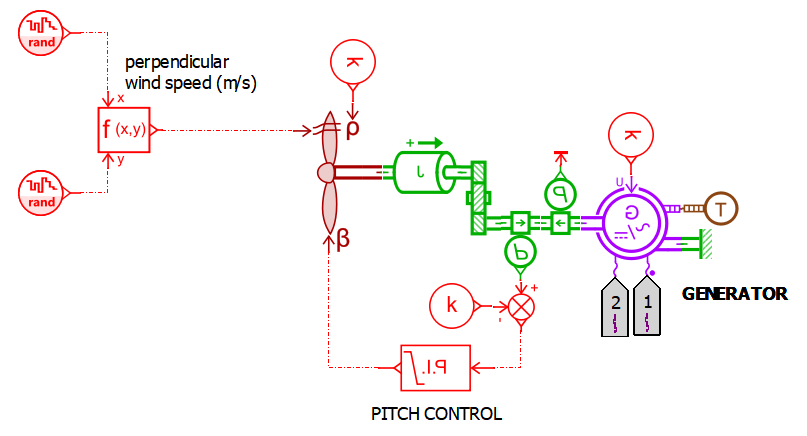

The wind turbine model is considering the number of wind turbines we want to use, the definition of the turbine geometry (especially the fan diameter, the pitch angle…), the generator performances, subcomponents losses and the fan pitch control.

Fig. 4: Wind turbine model

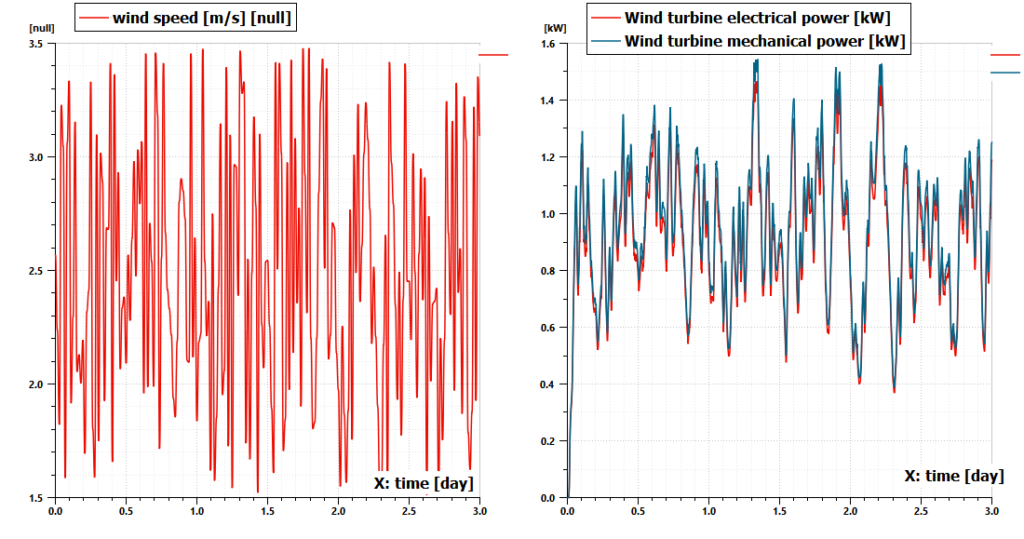

This model makes it possible to predict, for instance, the electric power and the mechanical power of the turbine depending on the wind transient speed.

Fig. 5: Wind turbine model results

Solar panels

The solar panel model is taking into account the number and geometries of cells and panels, the transient operating conditions: considering the evolution of the sun position and the impact of clouds and the definition of the solar array performances.

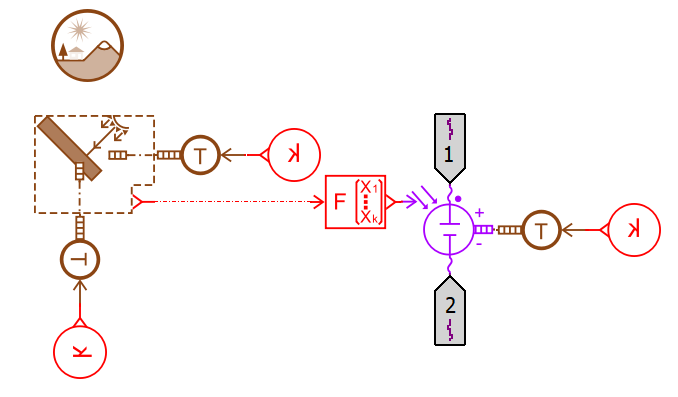

Fig. 6: Solar panels model

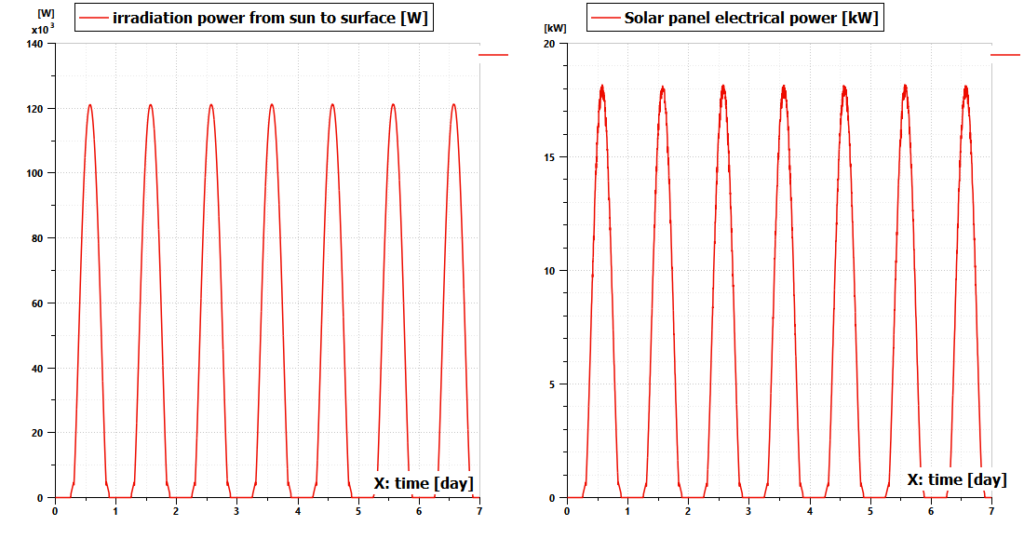

It makes it possible, for instance to predict the electric power delivered by the solar panel, depending on the transient irradiation power on the cells.

Fig. 7: Solar panels model results

Wave generator

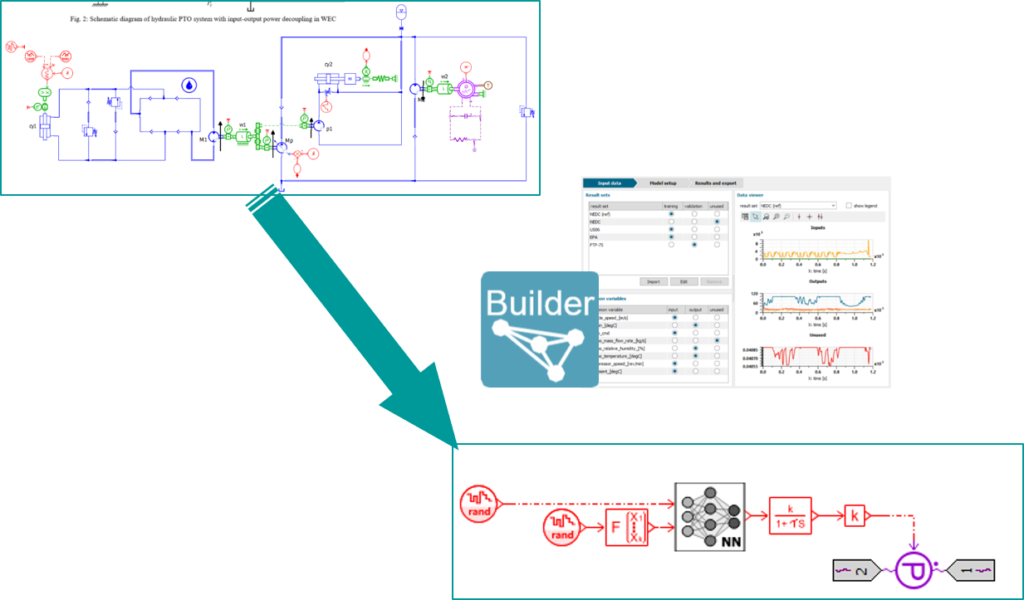

To predict the performances of a wave generator, we first built a quite detailed and multiphysics model. This model reproduces the detailed architecture of the system, considers the sizing and behavior of the subsystems: the piston, the valves, the hydraulic motor and generator, an accumulator, pipes, and so on… The model can take into account the transient operating conditions with variable waves frequency and amplitude.

This model is accurate and helpful for the wave generator detailed design and optimization. However, for long time simulation range simulation, it remains slow.

Then, in a second step, starting from the accurate model, we built a reduced model, using the Simcenter Amesim Neural Network Builder tool. The Neural Network builder makes possible to train a reduced model easily and quickly and to generate the corresponding Amesim model that will run very quickly. On a validation run, the reduced wave generator model can reproduce the results of the initial model with a level of confidence of 94% with a simulation time that is significantly improved. That’s quite incredible!

Fig. 8: Wave generator model reduction

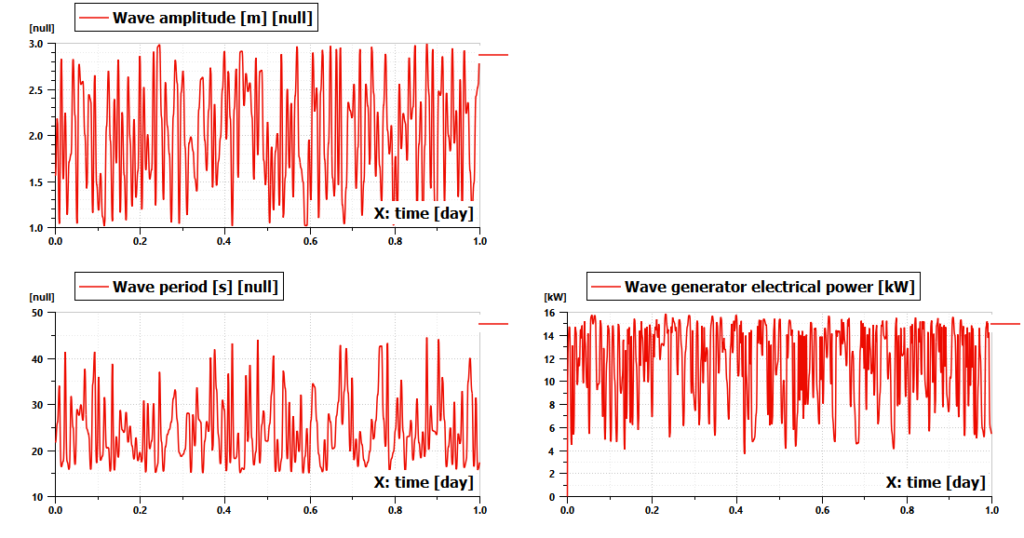

This reduced model can then be used to predict the electric power generated by the wave generator, depending on the wave frequency and amplitude with the performances we need in our green hydrogen production system model.

Fig. 9: Wave generator model results

Electrolyzer

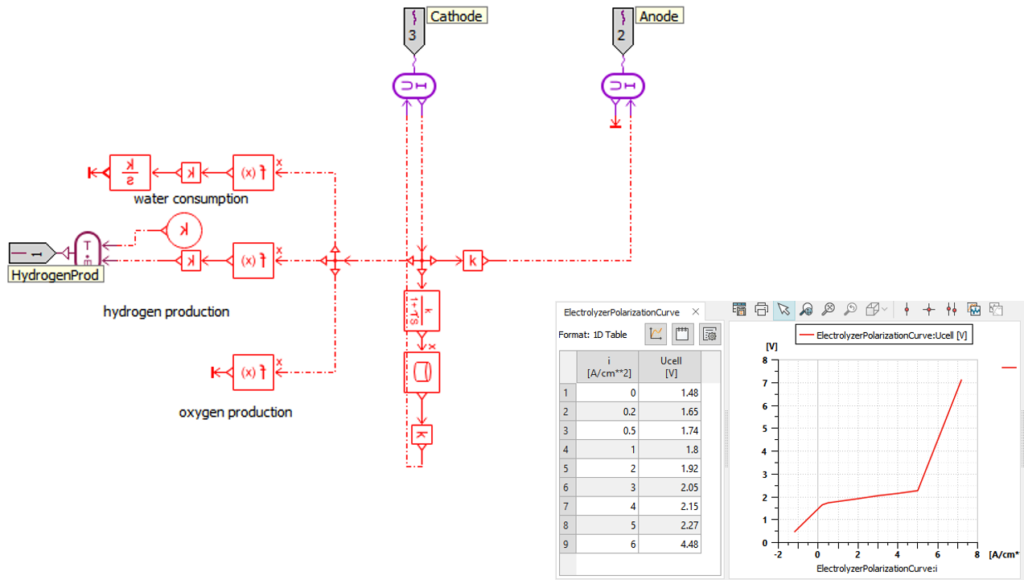

The electric power generated by solar panels, wind turbines and wave generators is combined and used by the electrolyzer. This will convert water into O2 and H2. In our model, the performances and reaction rates are predicted thanks to the polarization curve provided as a parameter, the number of cells and the active area of the cells.

Fig. 10: Electrolyzer model

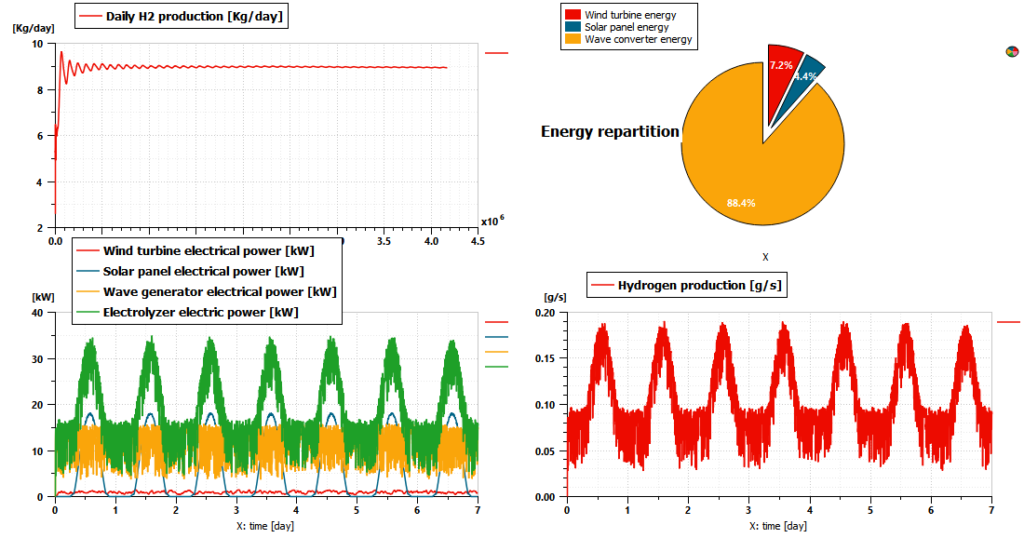

This makes it possible to predict the electric power used by the electrolyzer, the hydrogen instantaneous flow it will produce and the corresponding average mass you can produce per day. In our example, you can produce around 9 Kg of hydrogen per day.

You can also identify that with the sizing of our subsystems, the wave converter produces 88% of the electric power, the solar panels 4% and the wind turbine 7%.

Fig. 11: Electrolyzer model results

Hydrogen storage

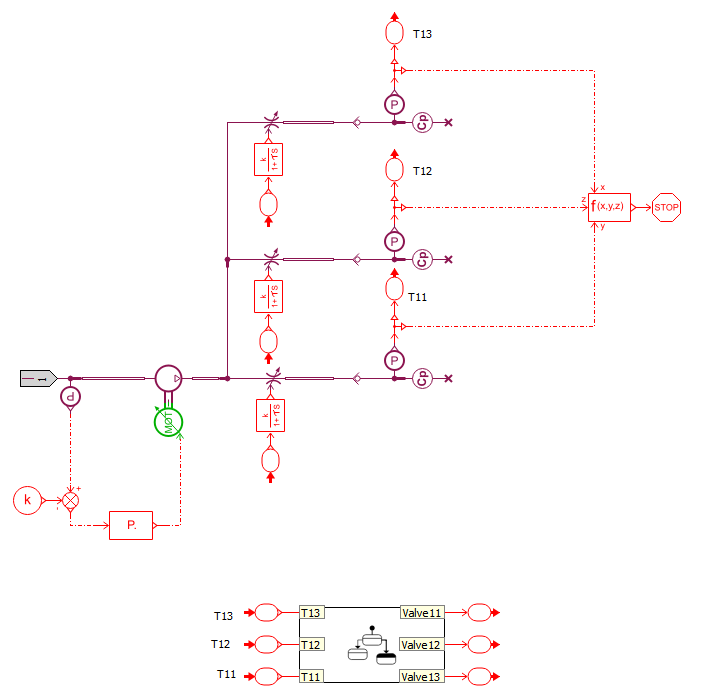

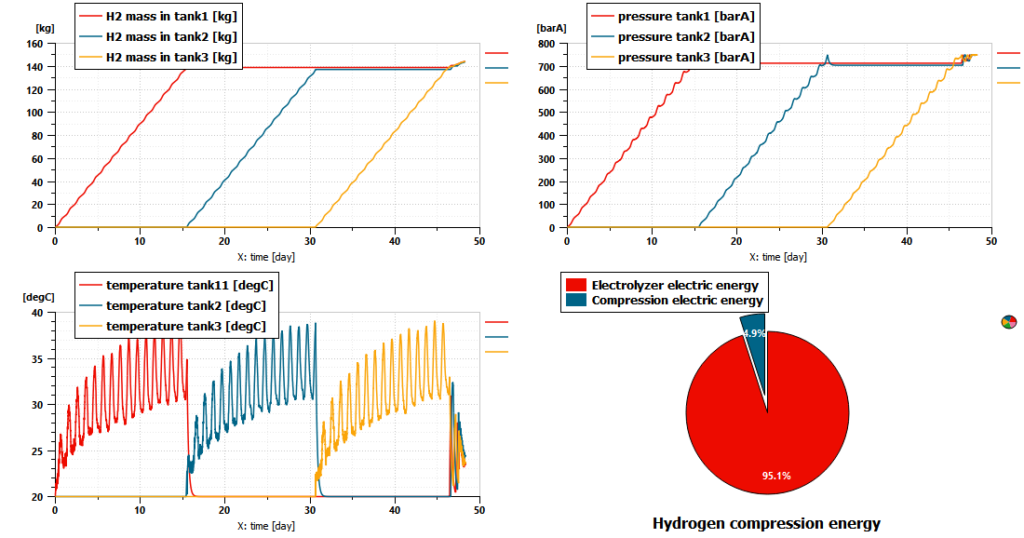

Finally, the hydrogen is compressed in the hydrogen storage model. This model is based on pipes, a compressor with its control, controlled valves and several tanks. The valves control allows the 1st tank to fill until the pressure reaches 750 bars. The 2nd tank is filled next and finally the 3rd. Thermal exchanges occurring between hydrogen, the pipes and the tanks are taken into account. The simulation stopped when the pressure had reached 750 bars in each of the 3 tanks.

Fig. 12: Hydrogen storage system model

Thanks to our model and the simulation, we can predict that in the operating conditions we have defined, we can fill the 3 tanks in 42 days. We can also clearly understand how fast we increase the pressure and the hydrogen mass or the evolution of the gas temperature inside the 3 tanks.

Compression of hydrogen at 750 consumes a part of the power generated by the solar panels, wind turbines and wave generators. It will then finally reduce the hydrogen production. Thanks to the simulation we can evaluate that the compressor consumes around 6% of the electric power.

Fig. 13: Hydrogen storage system model results

Conclusions

In conclusion, green hydrogen production simulation within Simcenter Amesim can definitively help address the challenges of green hydrogen production.

- The extensive multi-physics simulation platform makes it possible to model complete systems

- Sizing the different subsystems, considering various operating conditions is beneficial

- It makes it possible to better integrate subsystems and improve the overall performances and ROI

- Provides you with a better understanding of the system global behavior

- With system simulation, you can better design your system but also evaluate virtually and improve your control strategies

- You can finally select the right design at the 1st attempt, reducing risks of errors and accelerating your projects

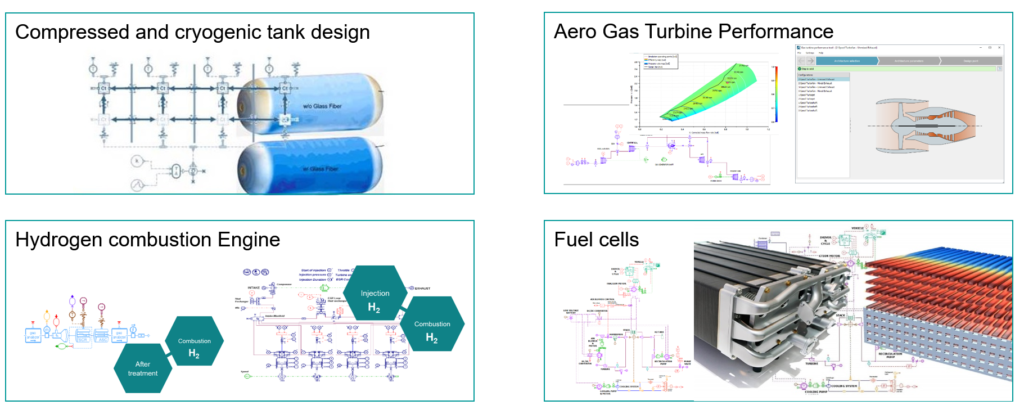

Finally, Simcenter Amesim, thanks to generic models and libraries makes it possible to address clean hydrogen production but also many other applications. We can mention briefly for instance the following ones:

- Design of hydrogen tanks integrated in a vehicle or an aircraft, considering high pressure or cryogenic tanks, simulation of scenarios as refueling or hydrogen extraction.

- Evaluation of the performances of aero-engine and gas turbines, analyze the bleed impact on multi-stage compressors, focus on engineering questions analyzing model for off-design and transient assessment.

- Design of hydrogen combustion engines, adapt the injection systems and controls, charging systems, combustion controls and after treatment systems.

- Fuel cells design and integration with the air and hydrogen supply, the power electronics, the thermal management and controls.

Fig. 14: Examples of Simcenter Amesim capabilities for other applications about hydrogen

About the author:

Patrice Montaland is a Business Developer for Simcenter Amesim. He first gained experience about simulation, fuel cells and hybrid vehicles as an engineer working in the automotive and the hydrogen industries. Patrice joined Siemens 14 years ago, he is now working very closely with the Simcenter Amesim development team, with a real motivation for better addressing the industry new challenges. Patrice strongly believes in the benefits of system simulation for designing green hydrogen production systems and improving the usage of the hydrogen in systems as for instance fuel cells thanks to a fast and comprehensive multi-physics modeling approach.

Read more

Learn how to master fuel cell design using a holistic simulation approach with Siemens software products thanks to this on-demand webinar.

Read more about how Simcenter Amesim can help to design and optimize hydrogen-fueled internal combustion engines with this blog.

Lear how to use Simcenter Amesim to build a hydrogen rocket engine digital twin with this paper.