Enhancing green design and energy saving for industrial machinery application with Simcenter Amesim

Rising energy prices and environmental concerns are changing the way industrial machinery manufacturers envision product design. Energy efficiency now comes to the top of the list during commercial discussions, side-by-side with the conventional productivity criterion. Industrial machinery manufacturing companies have become well aware that energy consumption is a key differentiating parameter for end customers upon scrutiny of long-term ownership costs, alongside maintenance and upfront cost of the machine.

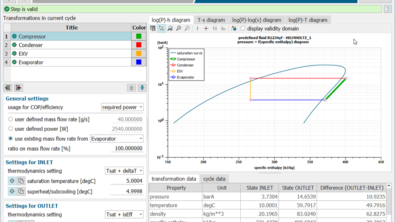

To respond to this shift, the industrial machinery sector is creating new optimized architectures and discovering model-based systems engineering (MBSE). Using this approach, Simcenter Amesim software from Siemens PLM Software for industrial machinery applications provides you the unique ability to evaluate interactions between subsystems with multi-domain modeling. You can implemented green design functionalities, which are helping you to save energy, monitor your losses and simulate energy dispersion according to design options before testing.

Simcenter Amesim uses the Bond graph formalism. A Bond graph is a graphical representation of a physical dynamic system, each part of the system is able to exchange energy bi-directionally.

In the example bellow, the input power for the electric motor is provided by a battery, the power is then transformed into a torque delivered to the drive shaft, and finally the output from the pump is a flow, while the input is a rotary speed.

Component such as electric motor, drive shaft and pump can exchange energy with the other parts, but also store energy or release energy with the external environment. For example, internal resistance of the electric motors dissipates energy as heat. Due to gaps between fixed and moving parts inside hydraulic pumps, leakages exist. So as to say that energy at the outlet of the elements is often smaller than the energy at the inlet, and tracking these losses is important to monitor the global system efficiency.

Specific analysis tools have been developed to quickly identify the losses, power or energy contributions. All power and energy variables are classified depending on their type: capacitive (C), resistive (R) and inertia (I) and can be animated with bar plots for easy replay and analysis of mission profiles.

A power flow chart can be developed and animated to better interpret the simulation results. By creating objects in the dashboard and linking them to the results of the simulation, users can easily visualize the power transmitted, power losses and efficiencies all along the working cycle

To conclude, thanks to Simcenter Amesim, costly physical prototype tests are reduced; the software is helping you to deliver high-quality and high-performance industrial machinery. Not only can you shorten time-to-market, but you can also endorse the conception of customized equipment and design more energy efficient machine.

Read an example about Simcenter Amesim use for industrial machinery application at Picanol.

Watch a video to see how Simcenter Amesim improved the energy consumption of a press brake.