Pump up the…Water?

How a classic solution can help our need for future energy storage

The sun is shining and then it isn’t. The wind is blowing and then it’s not. We learned to capture the energy from these sources, yet they continue to challenge us with their intermittency. Let’s build giant banks of batteries. Just more reason to push the hydrogen economy. Both of these technologies have their place in the future of energy storage. However, just as a variety of power generation options is required, so too is a variety of energy storage especially at the grid level.

Pumped Storage Hydropower (PSH) is already a well-established technology and according to the US Department of Energy, accounts for 95% of all utility-scale energy storage in the United States (2). In case you are like many and have never heard about it, let’s outline three important things about it: how it works, why it matters, and how to simulate it.

How it works

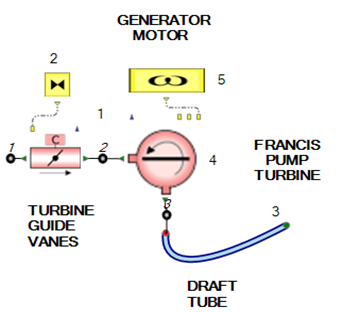

PSH works very much like traditional hydroelectric in that the flow of water through a turbine turns a generator ultimately creating electricity. However, where traditional hydroelectric relies on dams placed on rivers with the flow of water continuing in one direction, PSH uses connected storage reservoirs separated by elevation. It is this elevation difference along with gravity that provides the needed potential energy for the system to operate. This system connection also means that when other sources of electricity are available, such as solar or wind, the turbine can pump water back to the upper reservoir. Ultimately “storing” that clean energy in a different form for reuse when the electrical grid needs supplemental power.

Why this energy storage matters

As mentioned previously many forms of renewable energy can only produce electricity intermittently. The recent development in batteries receives the most public exposure especially when it comes to their use in electric transportation and even some at home storage, but their use on this scale is only recently gaining traction. While the cost has come down, they are still an expensive option. This is especially true when looking at grid level installations with much shorter average lifespans. There is also the concern that with wider deployment, it will put additional strain on the finite raw materials needed such as lithium.

Hydrogen and accompanying fuel cells are another area that is drawing significant attention. This is not a new technology, but one that has gained traction as an option for storing and transporting energy from green sources. Many in the automotive, aerospace, marine and power generation industries are exploring how hydrogen can be deployed. While certainly promising, it is not the purpose of this discussion since its application at a grid level is uncertain.

This brings us back to pumped storage hydropower and why it matters. These systems have a proven track record. They utilize technology that has been used since the late 1800s and can rely on many existing water reservoirs. They also easily allow for large energy storage on the range of gigawatt-hours and capacity in the hundreds of megawatts at a much lower cost. These system also have lifespans that can reach over 100 years with only occasional maintenance. For these reasons PSH is very well suited for stabilizing the larger energy grid.

How to simulate

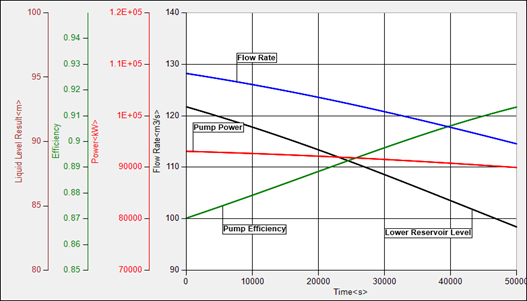

As with any of the systems mentioned, ensuring safe, reliable, and cost-efficient deployment and operation is critical to making them feasible. One obvious area of concern is to optimize the efficiency of the overall system performance. The purpose of the system is to raise the water from the lower reservoir to the upper reservoir using electricity generated by a green source. This means any inefficiencies are simply wasting that energy. Optimizing this overall process, helps the technology compete with newer options such as batteries and hydrogen. More options to better fit each situations needs mean a quicker transition to green energy.

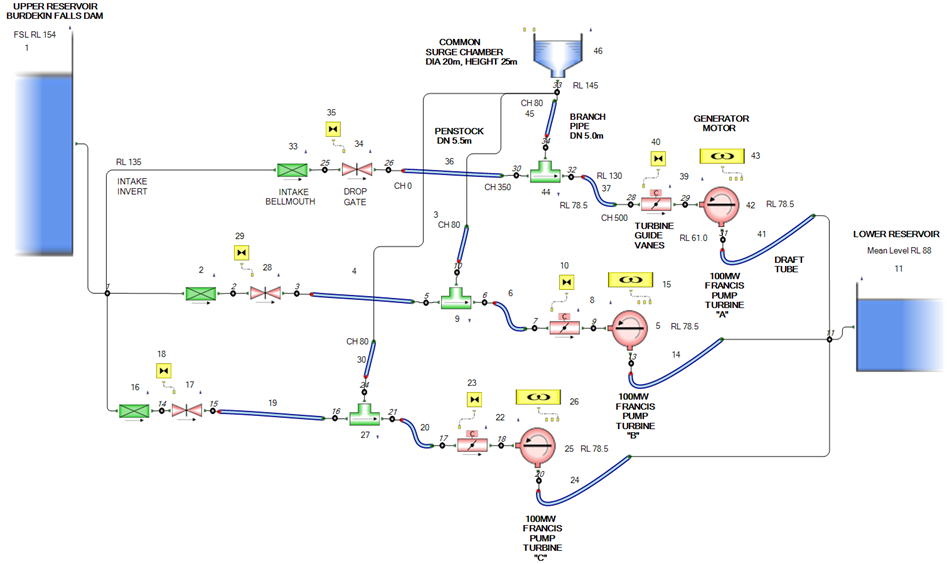

A discussion on how to design these systems is too large to cover in a blog. Luckily Jurgen Sprengel from JS Pump and Fluid System Consultants has done just that. His recent paper, Using Simcenter Flomaster to understand a hydropumped storage scheme outlines his use of Simcenter Flomaster to simulate the design of the full system. He discusses how components are sized and selected to maximize efficiency. He even shows how this was done for a design study of the Burdekin Hydro Pumped Storage scheme in Australia.

Spoiler Alert… they were able to achieve around 85% round-trip efficiency read to find out how!