Aiming for zero-emission buses

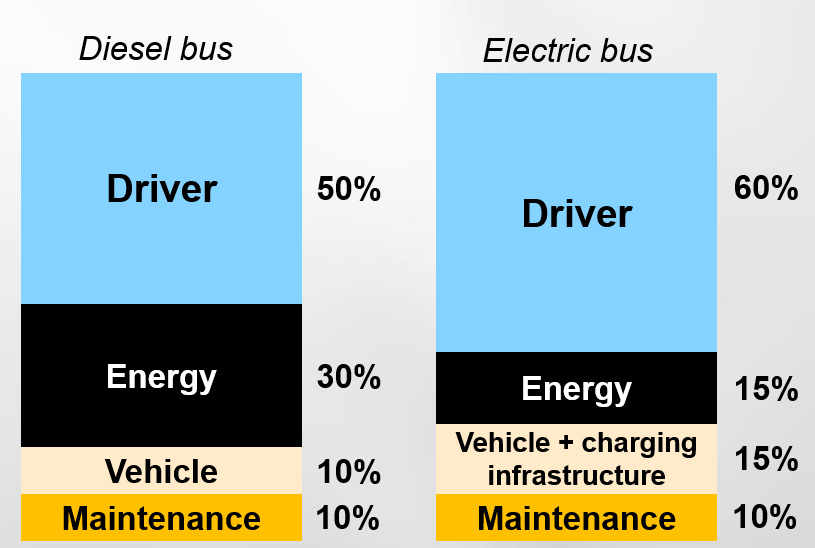

When considering switching to zero-emission buses, the transition can sound very expensive at first. Bus and coach manufacturer VDL discovered that shifting to an electric bus is even cheaper per kilometer than a diesel one! We met with Anouk Hol, aerodynamics and energy specialist at VDL, and discussed this new trend and its challenges.

Interestingly, there are a lot of similarities between the automotive and bus industries. “We can learn from car manufacturers, for example by using the same battery cells and packs”, she said. However, they have to make them bigger because they obviously need a bigger capacity. Buses are driving whole day long, they drive easily 300 to 500 kilometers a day. Besides, a city bus behaves very differently from a car: driving at a low velocity, stopping and opening the door every minute … The huge cabin and the passenger’ flow are also additional reasons why the components have different duty cycles and requirements.

Challenges of designing zero-emission buses!

With this new orientation, VDL had to suddenly strengthen software and control knowledge because they had to supply the full infrastructure. “When switching to zero-emission buses, we also switched from supplying a bus to supplying a system including charging infrastructure, helping customers with timetables…” says Hol.

Indeed, cities don’t have all the same bus and charging infrastructure: from a 24/7 service needing fast charging at bus stops, to a lighter service which can rely on bigger batteries and slow charging once or twice a day.

“We are really looking at what is the best solution for our customer: what is the best battery chemistry, fast charging, low charging, what is the best charging rate, how do we use it in the system climate…” Hol reports. But without the real bus available, there were so many options that it was not possible to just buy and test.

Use of modeling in the development process

This is where the need for modeling and simulation tools started to grow. Indeed, it was essential to know very early what the best configuration was to select suppliers before getting to the engineering and prototyping phases. This allowed them to make the bus as efficient as possible and propose to the customers a specific offer that best suits them.

On electric buses, the driver becomes the most expensive part, and that’s why optimization is so important: “It’s essential to optimize the battery size and reduce charging time as much as possible,” states Hol.

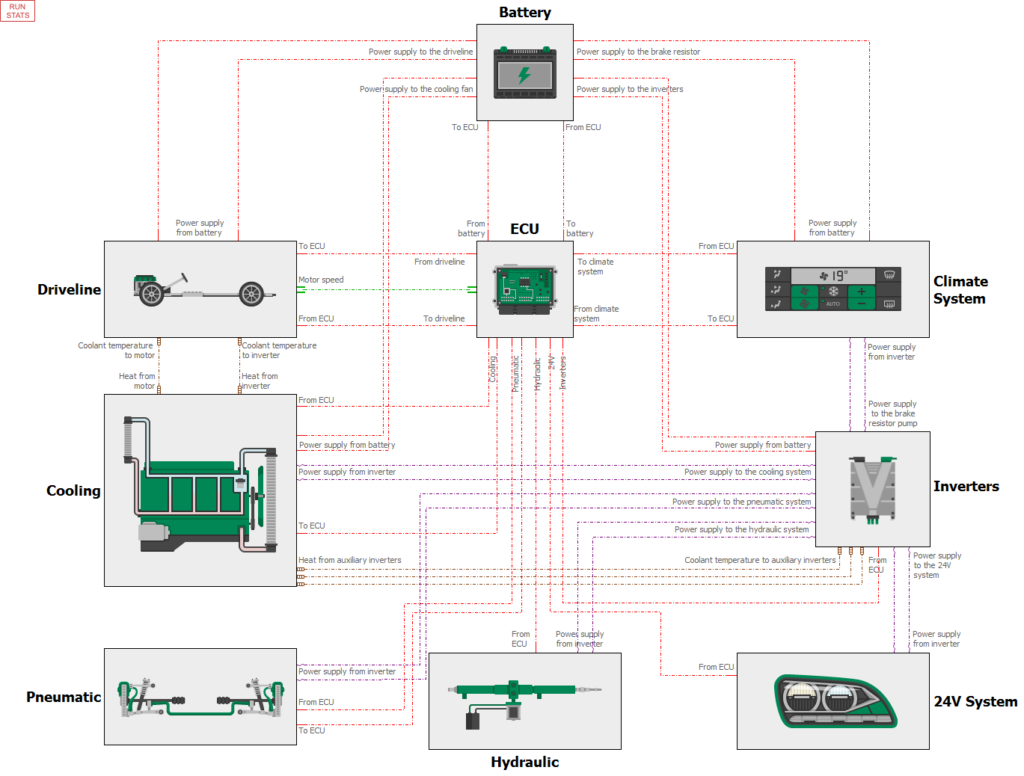

The simulation tool Simcenter™ Amesim™ software was used for several purposes. Before prototyping and measuring, VDL’s starting point was modeling. Using models, they could map energy flow in the vehicle, model and optimize component behavior, and optimize range and vehicle energy management.

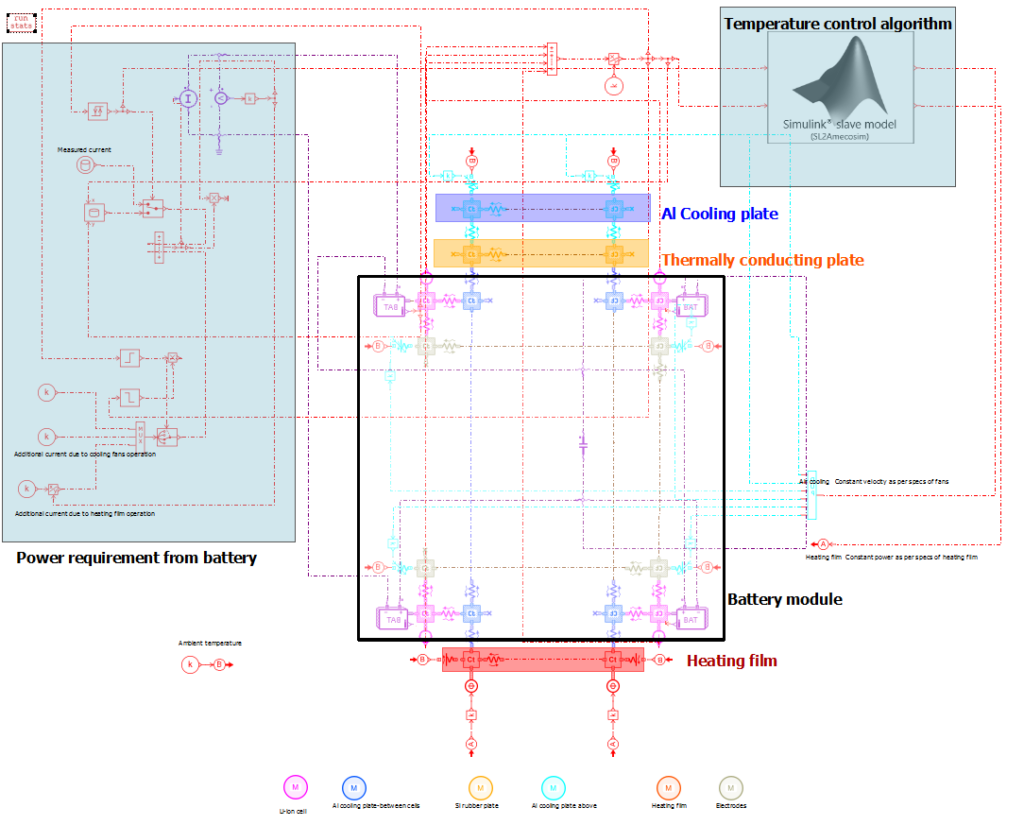

Detailed battery cell and pack modeling

First, they made detailed models of the battery’s cell and pack and ran simulations to see what the behavior of this system was, how to control it, and how to optimize suppliers’ selection. “We have nice components models we can use to select suppliers and components, but then we want to optimize the whole system,” says Hol. Combining all the components of one bus, including a vehicle control unit, and filling it with data like, for example, ambient temperature and route, they could run an analysis and accurately predict a lot of behaviors. These analyses also provided information on how all these components were interacting. “We can easily run analysis with only 5% error rate”, Hol says. Those models were also used for control design.

Mapping energy flows

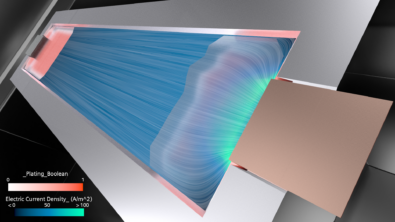

Second, simulation was also used for mapping energy flows in the vehicle, by coupling Simcenter Amesim with Simcenter™ STAR-CCM+™ software to import 3D information. For example, for the battery cooling, a fan is blowing air around the cells and this behavior cannot be included in a 1D model. “We got very great help with the Siemens colleagues here. We made a very simplified model which was easy to understand, and we could make a lookup table out of it which can include the 3D behavior in our 1D model”, concludes Hol. “For us, the integration between 1D Simcenter Amesim models and 3D Simcenter STAR-CCM+ models was very simple, and the run time is very good now”, Hol ads.

Battery management systems

Next, Simcenter tools are used to validate battery control strategies: a model of the battery and its cooling system, including electrical and thermal calculation, is connected to a model of the BMS to validate strategies and calibrate control parameters.

Modeling component behavior as well as mapping energy flows are both aimed at improving range estimation and optimizing range and vehicle energy management.

“The simulation models help us to easily do some analysis based on different usage profiles of our customers: different temperatures, different velocities, slopes, wind speeds…” says Anouk Hol. The customer was then able to clearly identify the reasons behind VDL’s selection.

More information about zero-emission buses and vehicles?

Whether for cars or buses, energy management optimization is a topic of interest. If you are willing to know more about this, check our selection below :

- Webinar: Optimize thermal management to improve electrified vehicle’s overall performance

- YouTube: VDL | Aiming for zero-emission buses

- Video on vehicle energy management: Reduce vehicle thermal management cost and time to market

Don’t miss our blog posts and how-to articles or go directly to our Simcenter Amesim webpage to learn more about our solutions.