How do vehicle system simulation models really behave?

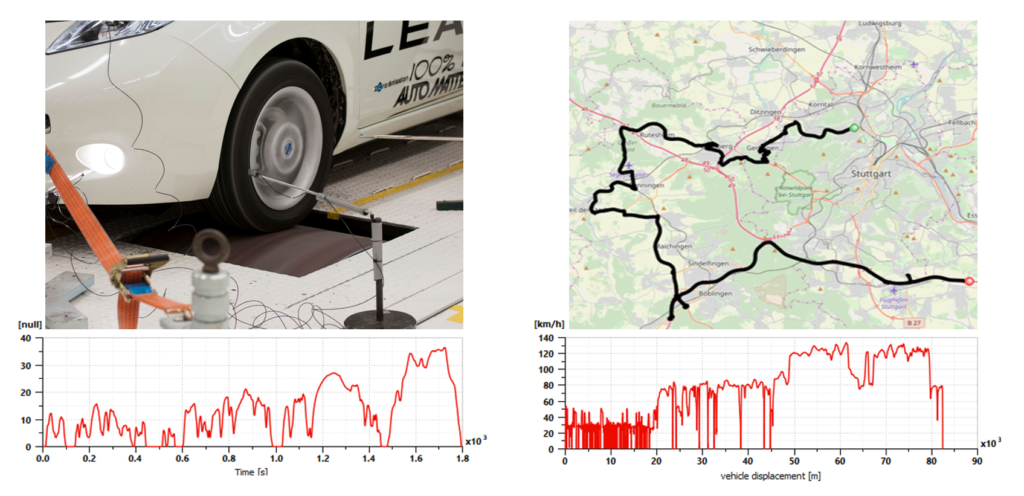

The transport industry has to cope with stringent regulations, aiming at reducing the vehicle fuel consumption and emissions. Beyond the well-known WLTP (Worldwide Harmonised Light Vehicles Test Procedure) and RDE (Real Driving Emissions), system simulation is used to evaluate wheel-based vehicles on more dynamic scenarios, closer to real usages.

To follow this trend toward more transient mission profiles, the IFP-Drive library in Simcenter Amesim has been updated over the last releases and provides with version 2020.1 an upgraded framework to model drivers and transmissions (and their controls) allowing a finer handling of complex scenarios and transient phases.

Whereas the main benefits on the driver side are linked to an enhanced usability with fully revised parameter settings and improved robustness, the transmission components present some new capabilities to better handle transient operations related to clutch actuation, gear shiftings and lock-up control.

Driver profiles for vehicle system simulation

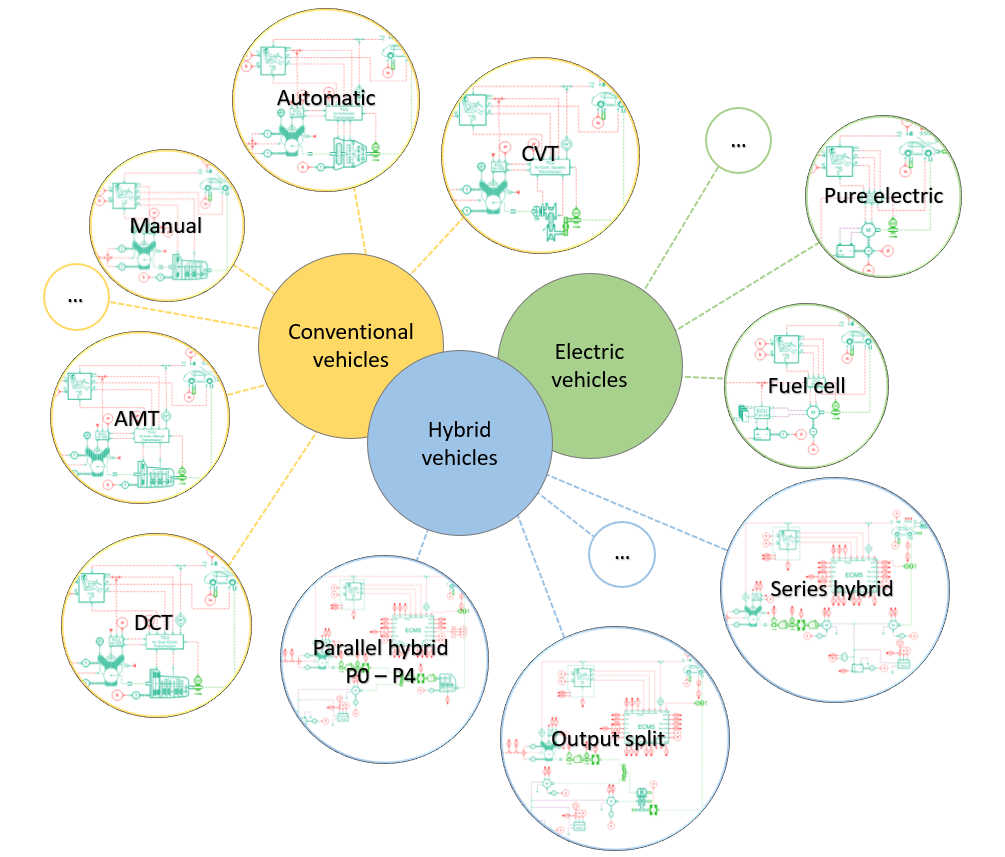

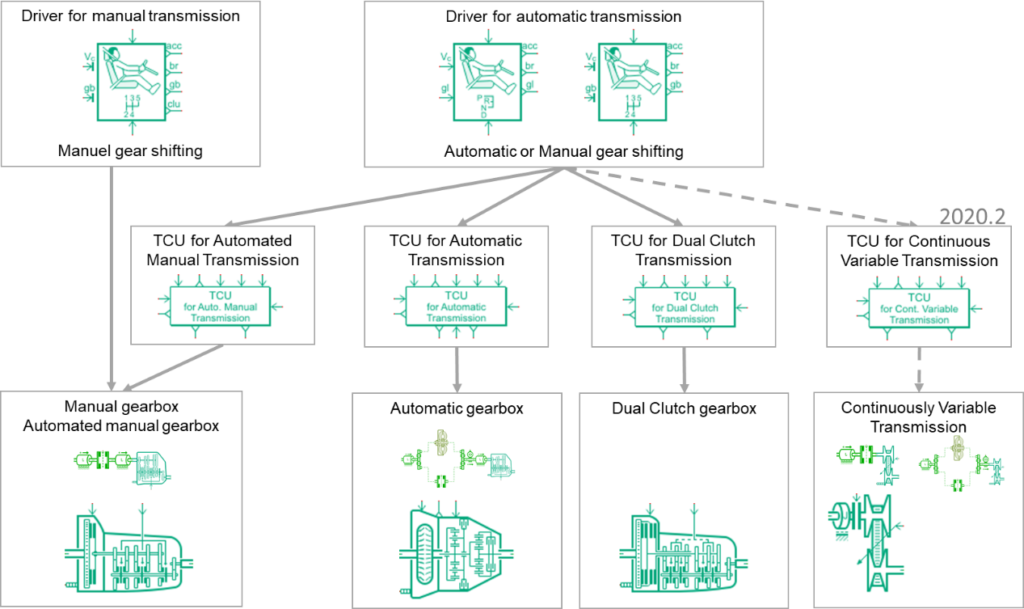

Simcenter Amesim offers three driver models for manual, manual automated and automatic transmissions. They address all kind of vehicles – from conventional to hybrid, fuel cell or electric, and cover all application domains – from light passenger cars to bus, trucks and off-highway vehicles.

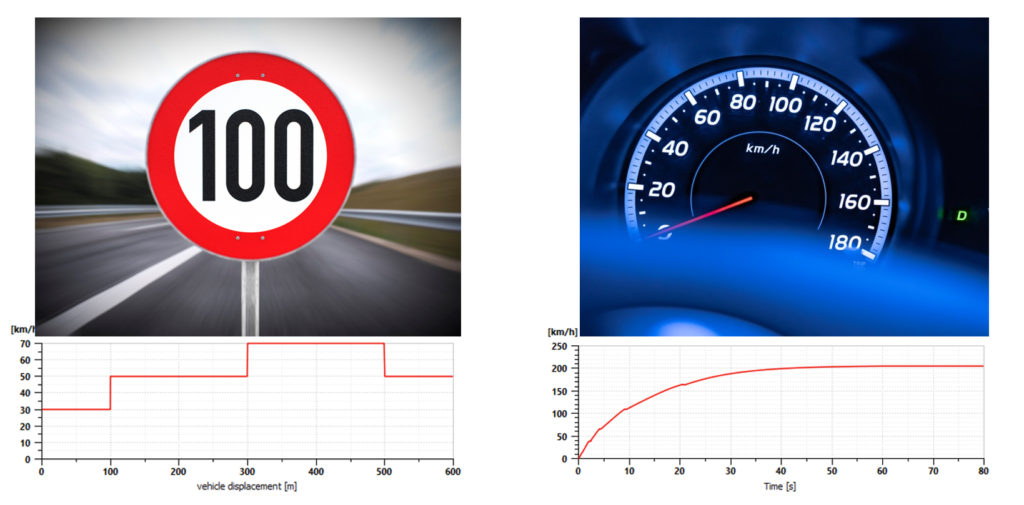

These models can deal with a large variety of scenarios from regulation-based driving cycles including RDE, to the handling of road speed limit segments, pure performance tests or application-specific mission profiles.

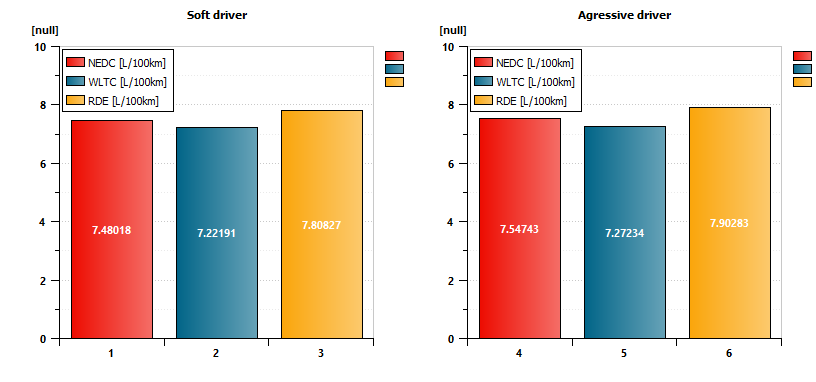

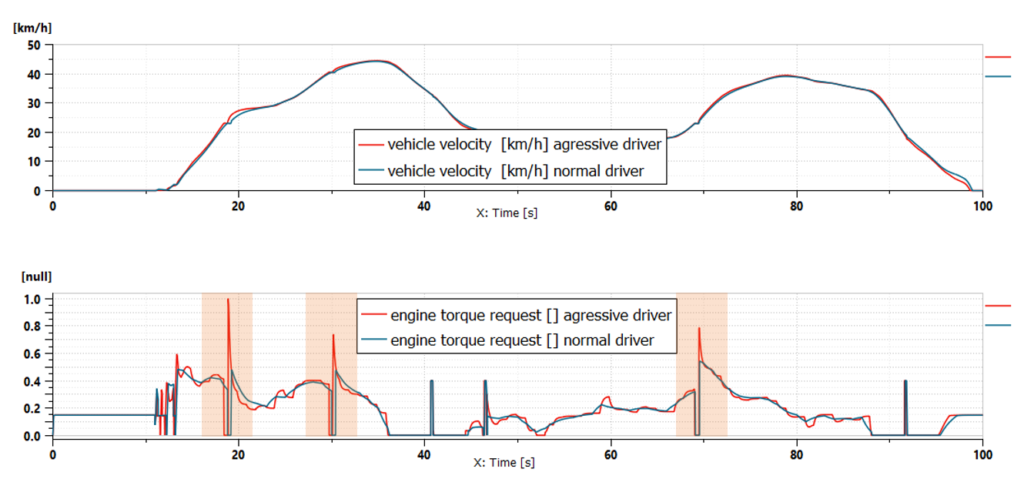

All drivers behave differently with an incidence on vehicle attributes. And you can now model various driving styles with an “aggressiveness” which can be easily set with understandable parameters. In addition, you can customize the driver time response during the transient phases of the cycle (gear shifting, clutch engagement…). All these “dynamic” aspects related to the driver profile impact fuel consumption: a few percent impact on the fuel consumption over standard driving cycles but a much more significant impact on the emissions directly linked to the engine load during transient phases.

The control logic implemented in this new generation of drivers is robust to changes in the vehicle environment (road slope, wind, road condition…) as well as vehicle characteristics (mass, tire dimension…), avoiding most of the driver model tuning efforts.

These improvements help you easily assess the influence of the driving style on vehicle attributes, such as fuel consumption and emissions. It also offers a robust framework for the quick evaluation of vehicle variants over complex mission profiles.

Extending transmission modeling capabilities

On the transmission side, the Simcenter Amesim IFP-Drive library offers a set of components to cover transmission types widely used in the automotive, truck and off-highway industries, with manual and automatic gearboxes, dual clutch and continuously variable transmissions. Electrified powertrains generally imply different architectures which can be fully addressed with Simcenter Amesim thanks to the Hybrid Optimization Tool.

The updated gearbox components present an improved usability and new capabilities toward a finer description of their operation during transient phases (clutch and friction plates actuation, synchronizer handling, lock-up). They are delivered with companion TCUs (transmission control unit) which are responsible for the realization of the driver requests through the control of the transmission actuators.

Whereas the gearbox components include mechanical considerations and require geometrical or function parameters, the TCUs pilot the transmission components and require more control-oriented parameters to set the control logics and actuation times.

Conclusion

We have demonstrated above the robustness and ease of use which we now offer in Simcenter Amesim to help you develop functional vehicle models. You can now address the simulation of close to real-life scenarios required for vehicle attributes evaluation. We have covered here functional modeling approaches, but you can extend the scope of your vehicle system simulation by using more advanced physical modeling capabilities of the Simcenter Amesim Transmission solution as well as the Powertrain library.

Want to know more about vehicle system simulation?

Watch our webinars:

- Optimizing exhaust systems for emissions reduction using simulation

- Evaluate your vehicle architecture to reach the best trade-off between performance, range and comfort

To learn more about other capabilities introduced to Simcenter Amesim 2020.1, read this blog post.

Authors:

Vincent Thomas: Senior Product Line Manager of engine and vehicle simulation within Simcenter Amesim.

Yohann Mangeot: Product Owner of the Simcenter Amesim internal combustion engine team; in charge of the development of the Vehicle Fuel Consumption and Performance library.