Right the first time

Shift left – Shift Right (1st part out of two)

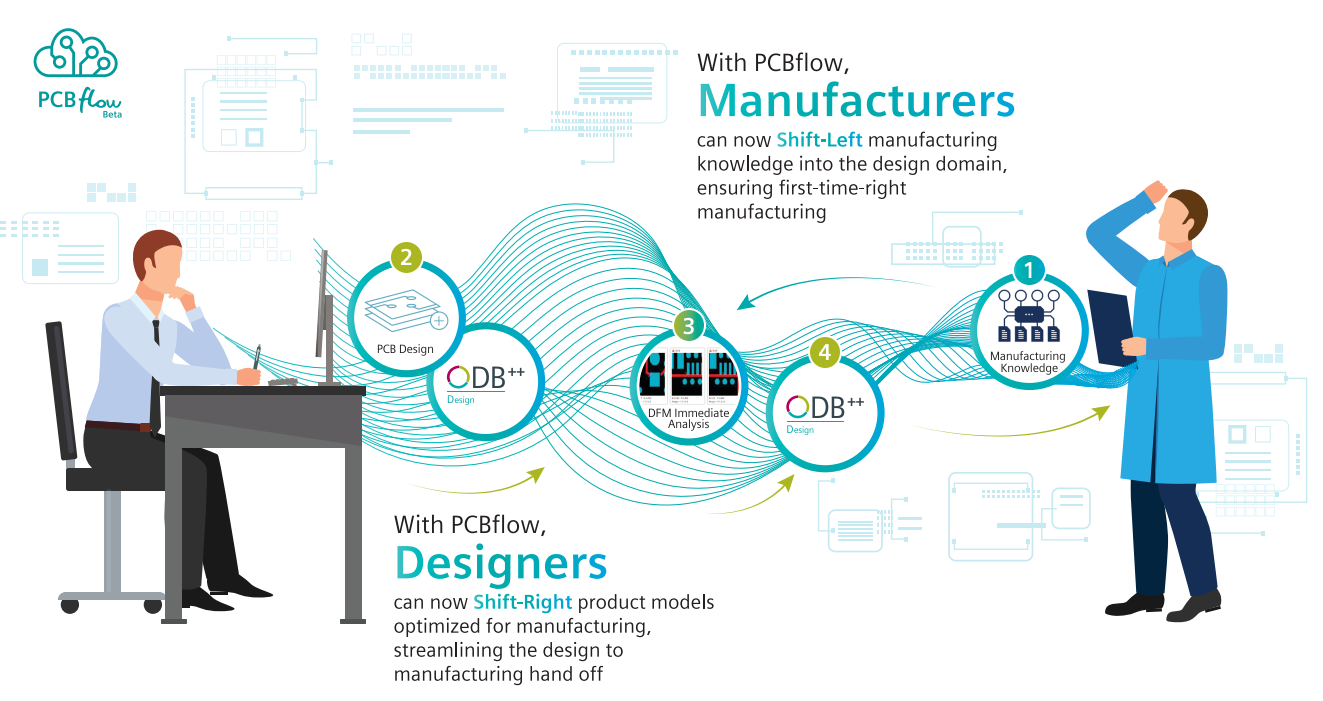

In 1887 the great city of Chicago in response to extreme weather decided to undertake a civil engineering project that was to alter the flow through their beloved city. The project was to reverse the direction of the Chicago River such that the water from Lake Michigan would flow ultimately into the Mississippi River minimizing concerns over flooding. For this accomplishment the hard workers of Chicago shifted their line of thinking in where the source of the water for the river began. This is not any different when pondering the PCB design to manufacturing transfer which needs to begin with manufacturing knowledge at the head water and then follows the flow of the water that fuels manufacturing downstream. With this in mind I had to ask myself a question, if we can change the direction of a river why is it we cannot enable PCB designers to target their manufacturing partners’ process capabilities over 130 years later?

The primary obstacle to enhancing quality of design entering into manufacturing the right-the-first time is often the reluctance on the manufacturing side to become as transparent as possible with their clients, the OEM’s. For years OEM’s have enabled their designers with best-in-class DFM applications and yet their suppliers are most often not readily willing to cooperate in a means that would be extremely effective. Instead only partial manufacturing needs is taken into consideration early in the design process, which results in many technical queries, inefficient data exchange and worst of all – avoidable revision spins each of which costs at least $20,000.

PCBflow, Valor’s best-in-class cloud DFM solution, was specifically created to enable the manufacturing process to swim upriver. PCBflow enables manufacturers to seamlessly and automatically provide their process capabilities in a secure and yet open manner. Access to process capabilities is controllable from a company, site and all the way down to individual design engineer. The method in determining which process capabilities should be applied is completely automatic and determined by the manufacturer which enables the designer to focus on getting the design ready for production while eliminating manufacturing delays and additional revision spins.

Designers can now begin to benefit through the use of PCBflow DFM analysis based on applying process capabilities of your chosen manufacturers. Upload your ODB++D product model into your PCBflow dashboard, select a manufacturer of choice and have the analysis performed – all online with no local software to install. PCBflow provides an interactive web-based analysis report along with a downloadable PDF report that is available for sharing.

The answer to my opening question is simple. The water had no choice, but you do, and my next question is are you finally up to enabling right-the-first time manufacturing? If your answer is yes then please join PCBflow and be part of the PCB right-the-first time revolution.