What’s new in Opcenter Intra Plant Logistics 2210

Improving user experience for Opcenter Intra Plant Logistics.

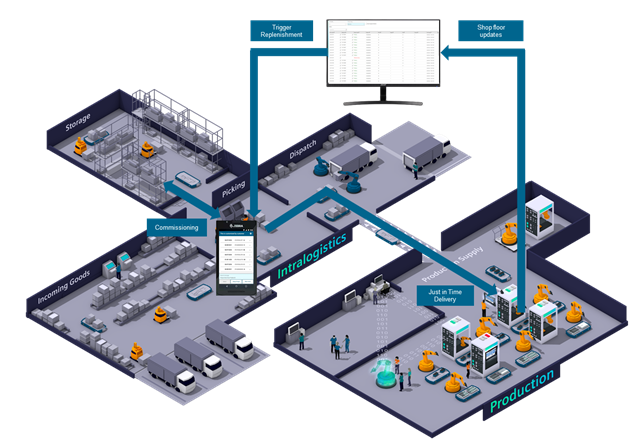

Logistics management inside of the factory occurs in different places and levels, requiring different types of support to efficiently keep track of your inventory. The Opcenter™ Intra Plant Logistics (IPL) solution addresses this need, providing kanban, changeover and just-in-time (JIT) principles to manage a consistent material flow to the production lines based on the schedule, actual demand and consumption.

It provides you with logistics capabilities including a flexible solution to address your production needs and significantly reduce inventory, maintain material specification, orchestrate your warehouse activities and ensure a smooth manufacturing flow.

Some features from this release:

- JIT and changeover support for Opcenter Execution Electronics manual and final assembly stations

- Opcenter Intra Plant Logistics configuration UI – smart settings

- New Opcenter Intra Plant Logistics portal for web applications

- New Opcenter Intra Plant Logistics web configuration pages

- AGV integration via SIMOVE

Benefits of Opcenter Intra Plant Logistics 2210:

- Improve configuration efficiency for Opcenter Intra Plant Logistics and MES

- Reduce inventory and costs while improving performance

- Improve user experience

- Reduce total cost of ownership

- Cut deployment time and cost

Already using Opcenter Intra Plant Logistics? See what’s new in version 2210.