What’s new in Opcenter Execution Process 2401

Leveraging quality checks to deliver product reliability, consistency, and success.

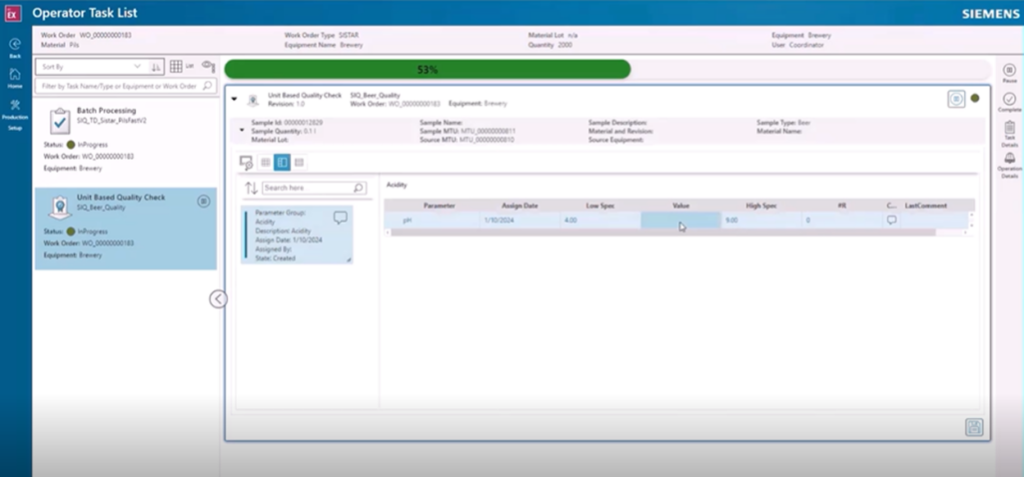

Ensure perfect quality

Opcenter Execution Process supports increasing traceability, raising order management efficiency, and the real-time monitoring of process manufacturing operations.

Institute a high degree of vertical integration

Orchestrate and manage the distinctive aspects of manufacturing consumer packaged goods (CPG), food and beverage (F&B) and chemical manufacturing. Meet both the special requirements of formulated product operations and the demands of secondary manufacturing operations, like packaging, labeling and palletizing finished goods, with a unified MES for process manufacturing.

Manage materials, formula, recipe and batch management

Reliably determine and track variable key performance characteristics of incoming raw materials (acidity or viscosity, for example) as well as time-sensitive parameters (ripeness, shelf life). Rely on close integration of our MES for process manufacturing and a specification management system to gain efficiency and accuracy in managing formulas, recipes and bills of materials (BOMs). Make product and process adjustments to account for supplier differences and improve final product consistency.

Opcenter Execution Process 2401 brings you the following benefits:

• Enable regular quality checks to make sure products consistently meet predefined standards and specifications

• Support continual product quality improvement

• Configure and execute at line and offline laboratory tests

• Integrate with Opcenter RD&L and SISTAR BRAUMAT (the innovative control system for the brewing industry)

• Synchronize business with manufactur¬ing, including integrating automation and batch execution

• Integrate quality tests in shop floor processes, including lot quality control and information exchange with labora¬tory personnel

Opcenter Execution Process 2401 brings a lot of valuable capabilities, here are some of them:

• Institute a high degree of vertical integration

• Manage materials, formula, recipe and batch management

• New Opcenter Execution Process migration Guide

• Export/import solution configurations – Roles and function rights, commands (pre-checks and post-actions) and worker roles

• AWS cloud practice documentation

Already using Opcenter Execution Process? See what’s new in version 2401.

Want to learn more? Using Opcenter Execution Process as a MOM platform enables seamless integration with scheduling, quality, and manufacturing intelligence, which delivers interactive dashboards for analysis of production data.

For New Product Development & Introduction, Opcenter Execution Process enables the transformation of recipes from “generic” specifications to detailed “master” instructions, ready for order scheduling and execution. Find out more about Opcenter Execution Process.