Unlock the full potential of your manufacturing execution system with low code

In today’s market, personalized manufacturing execution system (MES) software is crucial to success. One-size-fits-all interfaces do not provide the flexibility and nuance necessary to meet modern needs, making it difficult to meet specific operational requirements as industry demands evolve.

What’s needed is:

- Personalized and adaptable MES software powered by low code

- Industry-specific templates with intuitive user interfaces (UI)

- Seamless integration of these interfaces into various manufacturing systems

In a recent webinar, Opcenter and Mendix experts Benedetto Bozano and Kjelle Frederik Meudt demonstrated how discrete and process manufacturers can leverage low-code technology to unlock the full potential of their MES software.

This article reviews key takeaways from their presentation, including demos of Opcenter applications and Mendix functionalities. Read on for the presentation highlights and watch the entire on-demand webinar to discover more ways to leverage low code to your advantage.

Enhance manufacturing efficiency and user experience

Siemens Opcenter Execution is an MES solution designed to optimize manufacturing operations by increasing visibility and control of production and processes across the entire enterprise.

The software now offers embedded low-code capabilities from Mendix and out-of-the-box low-code templates tailored to serve various industries with high- and low-variance processes.

The modular framework is designed with flexibility in mind, allowing users to easily add apps that meet specific customer requirements as needed. This approach optimizes efficiency and productivity on the manufacturing floor, ensuring that the MES remains agile for unique or evolving operational needs.

The user interface of Opcenter Execution reflects this adaptability with UI templates that are persona-based, industry-specific and process-centric. These templates can be implemented using Mendix low-code technology, so you can use them directly out of the box or adapt them to meet specific requirements. The low-code technology facilitates and simplifies customization, making it accessible to users with limited coding skills.

The array of out-of-the-box low-code UI templates offered through Opcenter Execution is expansive and continues to expand, accommodating a wide range of industrial and process needs to ensure that your UI evolves alongside your products.

Enhance operational efficiency with low code

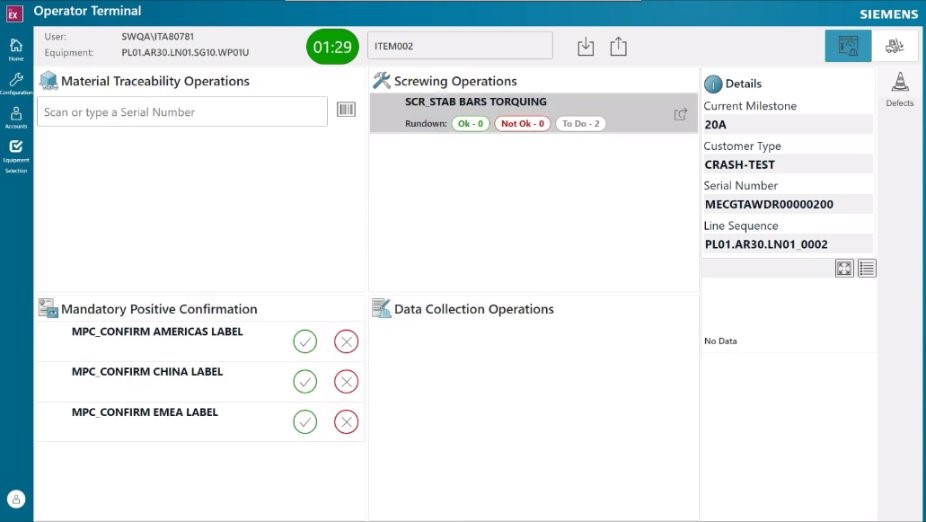

Opcenter Execution offers the one-piece flow app to help users enhance operational efficiency in fast-moving, highly automated manufacturing environments. Designed for productive operator interaction, this app provides lean operator terminal screens that display only the essential information needed for the task at hand. This streamlined interface ensures operators are not distracted by unnecessary data, allowing them to focus on immediate tasks.

Integrating the one-piece flow app with shop floor automation systems is crucial to its functionality. Information on the operator screens is automatically refreshed whenever a piece enters or leaves the workstation. This seamless update process eliminates the need for manual data entry or refresh, reducing the potential for human error and increasing the speed of operations.

The automatic refresh feature ensures that the data displayed is always current and relevant to the specific piece at the workstation, further enhancing efficiency. This capability supports a lean manufacturing approach and contributes to a reduction in cycle times and an overall increase in production throughput.

Navigate complex manufacturing with a personalized MES

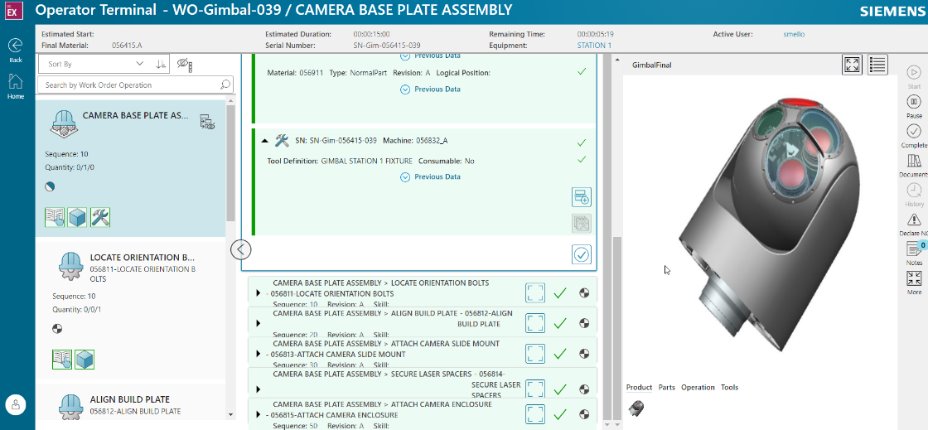

For operations in which products are often engineered to order — requiring operators to perform intricate assembly tasks manually — the need for robust MES is critical. Another application of Opcenter Execution, the complex manufacturing app, is designed to address these challenges.

To ensure efficiency and accuracy, this app is equipped with detailed screens that provide operators with comprehensive work instructions. These instructions are displayed in a vertical format, enabling operators to navigate through their tasks with ease. This format facilitates a smooth workflow and allows operators to preview upcoming tasks and review those already completed.

The system enhances task visibility with consistent color coding and iconography, marking completed tasks clearly, helping to maintain operational flow and reduce errors. Additionally, the vertical layout is designed with sequence and collapsibility to simplify navigation, allowing operators to concentrate on current tasks by minimizing distractions from non-relevant information. This application is a game-changer in scenarios where each piece’s uniqueness requires precise, guided operations.

Check out the video below to see the complex manufacturing app in action:

Level up MES capabilities with low code

Mendix is a low-code platform offered by Siemens to help organizations develop personalized applications and integrate their existing manufacturing systems.

Using connectors and APIs, Mendix makes integrating data from various systems easy, ensuring that data flows seamlessly across platforms. It offers tools to help users develop applications on top of those systems, allowing organizations to fluidly manage their manufacturing processes and extend their MES capabilities.

To further accelerate the app development process, the Mendix marketplace offers reusable assets that allow organizations to implement solutions more rapidly and efficiently. The marketplace is continually updated with new and improved assets from a community of partners and developers.

Streamline materials management with a Kanban board

Material Kanban, a Mendix application, can be integrated with Opcenter for effective materials management. This synchronization enables real-time, automatic handling of material requests, simplifying and enhancing the efficiency of warehouse processes. Utilizing a Kanban board within an MES serves as a pivotal tool in streamlining operations, making the management of materials more accessible and less prone to errors.

The automatic nature of material requests reduces the need for manual intervention, producing a more streamlined workflow. The system is meticulously designed to keep all stakeholders updated in real time, ensuring that material levels are adequately maintained and replenished efficiently. This proactive management tool prevents the typical delays and errors associated with manual handling, promotes a more agile and responsive operational environment, reduces inventory costs, and conserves storage space.

Watch the video below for a material staging demo using the Material Kanban app:

Take your MES to the next level with low code

No matter your industry, low-code apps can help your organization extend your MES capabilities and optimize production processes. For even more applications and use cases supported by Opcenter and Mendix, watch the full on-demand webinar here.

Interested in learning more? Check out these additional resources:

- Ebook: Personalized and adaptable MES accelerates innovation, improves flexibility and increases efficiency

- White paper: Meeting ambitious production goals

- Analyst report: Siemens recognized as a leader in MES